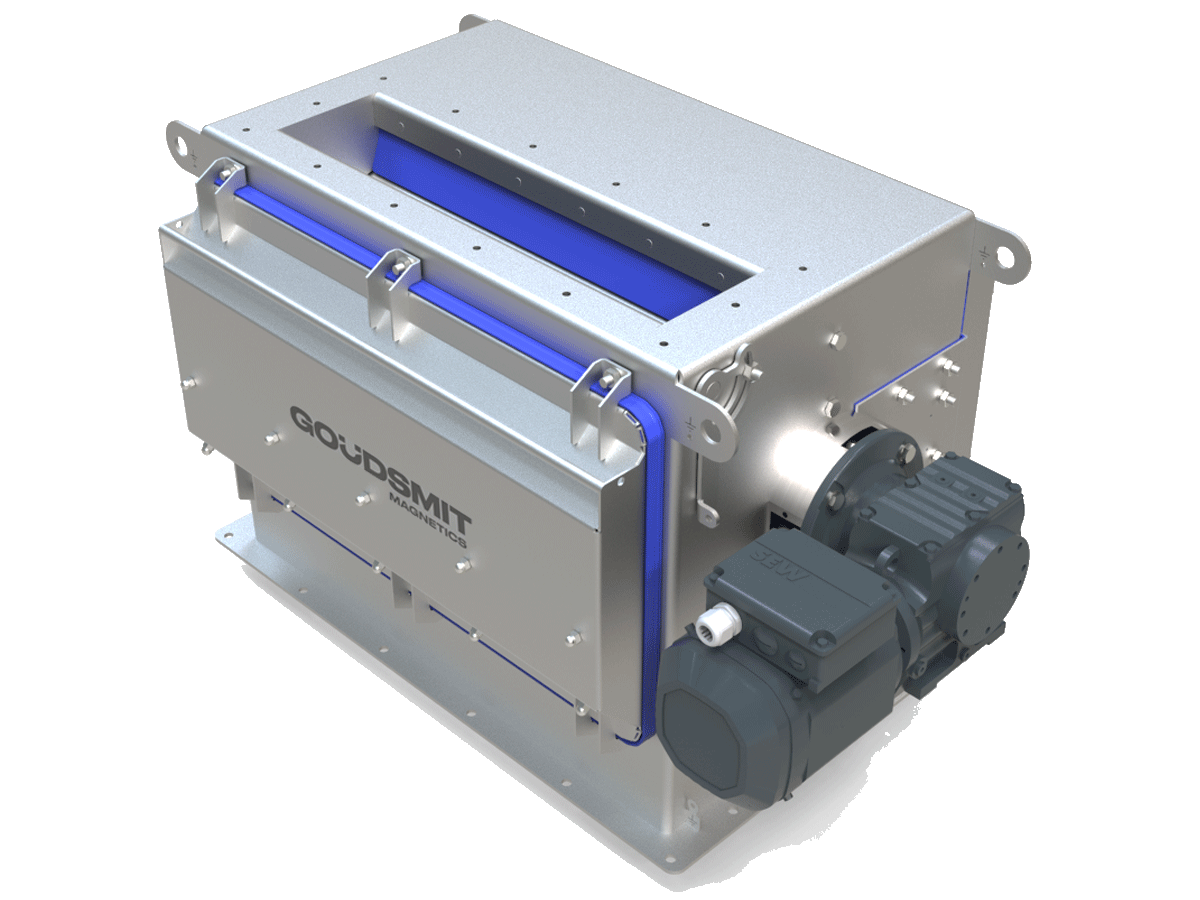

We have recently developed a new series of magnetic drum separators especially for the intake of foodstuffs. These magnets remove ferrous particles and weakly magnetic particles as small as 0.03 mm from free-falling granular products in the said industry. The ever-increasing demands on magnetic force and material certifications have led to this modified design.

The drum magnet, which is made entirely of stainless steel, has an EC1935/2004 certified seal and a magnetic force that varies optionally from 1,800 to 8,000 gauss. Magnetic drum separators prevent metal contamination of end products, as well as unnecessary damage to, for example, mixing or grinding machines. They are suitable for product flows with a lot of magnetic contamination.

Continuous process

The advantage of a magnetic drum separator is that the metal separation can take place in a continuous process and that this system can process large capacities. The product flow does not have to be stopped to clean the magnet; the new version has ample inspection options. The magnet makes direct contact with the product, attracts the magnetic particles and carries them to the bottom of the drum. Here the particles drop off and are collected and/or carried away.

Design

The magnetic drum separator has a hygienically finished housing; there are no points where product can stagnate and the whole is smoothly finished and non-stick. This unit contains a complete neodymium magnet system and removes ferrous and even weakly magnetic particles particles from 0,03 mm from raw materials with a maximum particle size of 50 mm. For the removal of small, slightly magnetic particles such as Type 304 stainless steel, we advise placing a vibratory feeder for the supply of materials.

Heavy magnetic particle contamination

Due to the continuous cleaning, magnetic drum separators are very suitable for product flows with heavy magnetic particle contamination. You can use them for dry powders and granulates in free-fall pipelines, or after a vibratory feeder in belt conveyors. The magnet is available in various sizes. We supply magnetic drum separators for coarser raw materials such as granulates and fibres in the plastics or ceramics industry.

More information?

Please use the contact form.