‘Magnetic measurements give automotive suppliers the guarantees they need,’ is Marc Teeuwen's answer to this question. ‘Firstly for ourselves, because these measurements are simply a standard part of the ISO/TS process, and above all for our customers in the automotive industry.’

CPK Value

These measurements are used to calculate what is called a 'Cpk value', which is necessary to guarantee a reliable magnet for products such as actuators, sensors and electric motors. The Cpk value is part of the statistical process control and provides information about how well the manufacturer controls their process.

Control the process

The higher the Cpk value, the better the magnet supplier's control of the process. This makes the statistical chance of non-conforming products negligible. And since our final inspection is also our customer's inbound inspection, this also reduces the chance of failure in cars, machines and systems after delivery.

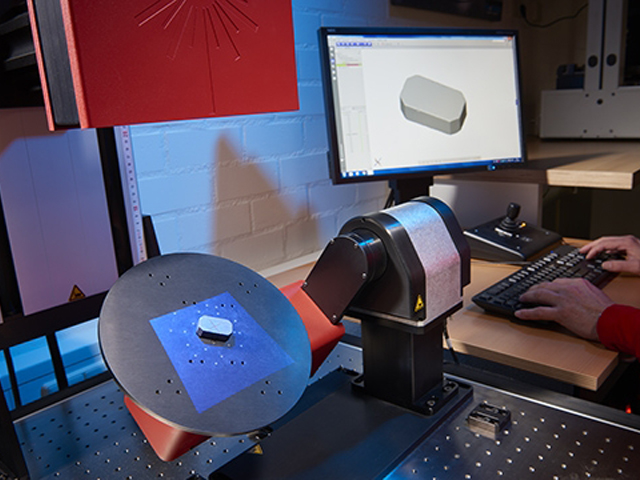

GOM 3D Scanner

Marc explains: ‘Let's say you have the nominal dimensions of a magnet with a plus or minus tolerance. When the value measured by the GOM 3D scanner is very close to the nominal size you get a high Cpk value, which shows that a manufacturer has their process well under control. This means that the statistical probability of obtaining a magnet that lies outside the tolerance band, and would therefore be rejected, is very small. The GOM 3D scanner measures the magnet and automatically generates a report in which the Cpk value is derived from the measurement data. This is very important to our customers.’

Magnet tolerances

‘When you have a block magnet in front of you, you see the dimensions: L x W x H. Suppose the length is 20 mm and the standard tolerance for this dimension is ± 0.1 mm. This means that the length of the magnet we deliver must always fall between 19.9 and 20.1 mm. It is also important that the tolerances do not vary too much: they should all be right around 20 mm, with as little deviation as possible. The smaller the deviation from 20, the higher the Cpk value is.

No rejects

This also reduces the chance that a magnet will be out of tolerance. If the tolerance line is flat, a manufacturer process has good control over their process and there is little chance of rejects. The GOM 3D scanner presents this visually in the measurement report. For an automotive supplier this is extremely important: it serves as their proof that the products they deliver meet the highest requirements. Moreover, many automotive suppliers make this report and the Cpk value a contractual requirement.

Magnets in cars

Where are magnets found in cars? Marc: ‘In the gearbox, sensors, brakes, water pump, engines, ignition coil, alternator and starter motor, but also in the increasingly popular lane departure warning system, which produces a warning beep or vibration signal if you stray outside your own driving lane. This is achieved with magnets, and they must do their job properly or motor vehicle accidents can occur. Measurements are therefore crucial.’

More information? Please use the contact form