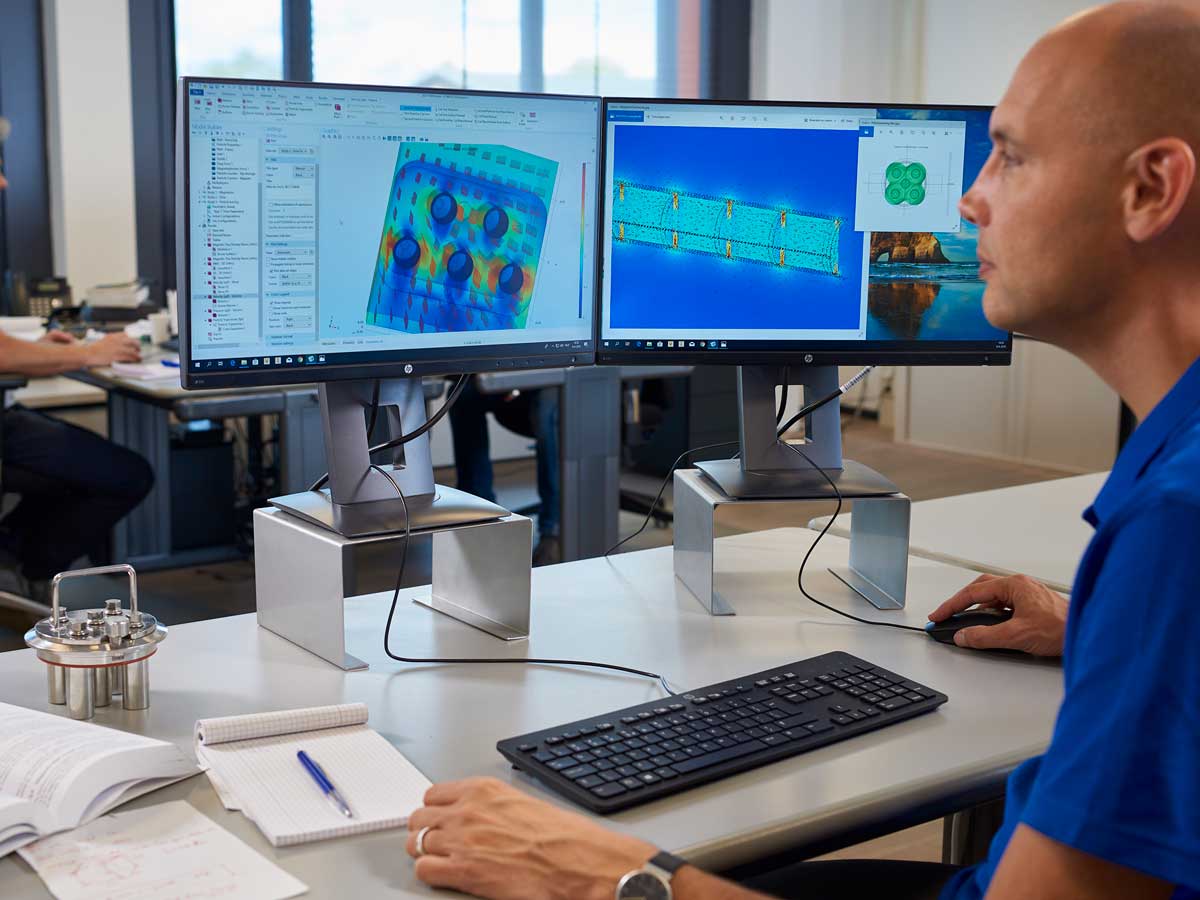

With the recently purchased software for magnetic calculations, Martijn Leskens, R&D engineer at Goudsmit Magnetics, uses the finite elements or FEM method to show how a product behaves in a magnetic system and quantify the magnetic performance. Martijn: ‘We can efficiently optimize this product performance with magnetic calculations. This allows us to accurately predict how a magnet will behave in terms of depth of the magnetic field, which is called the “magnetic flux density”, and in terms of force on another ferromagnetic object.

Separation efficiency of magnets

We can also estimate the separation efficiency for removal of steel and stainless steel particles from a powdered, gaseous or liquid product flow, as can be found in the food industry for example. We use the Comsol calculation program for this. It provides a very accurate estimation of the real-world situation.’

Magnetic field

The following video shows how both steel and stainless steel particles in the product—in this case water, but this could also be a liquid foodstuff—behave in the magnetic filter and how they flow through the magnetic field and are captured. This provides insight into the effectiveness of the magnetic field and the influence on the separation efficiency of magnetic properties, as well as on the size of the particles to be captured and the flow profile. The metal pollution must pass through the magnetic field. We demonstrate this with calculations. By comparing several videos we can also demonstrate the difference in separation efficiency as a consequence of particle size.’

Video 1 - FEM calculation for magnetic filter (for steel particles)

Video 2 - FEM calculation for magnetic filter (for stainless steel particles)

Magnetic Flux density

Why is demonstrating this separation efficiency so important? We asked colleague Guy Mutsaerts, expert in the field of magnets for the food industry. Guy: We know that to capture iron, or Fe, you need at least 155 gauss, and for grade 304 stainless steel you need at least 1100 gauss. This simulation allows us to see whether this is theoretically achieved. We are currently testing the theory in practice to achieve a definitive separation guarantee. These tests take a lot of time. We have set ourselves a minimum requirement of >300 gauss for the capture of ferrous particles. Goudsmit is the only magnet supplier in the world that uses this program for magnet calculations and can provide this guarantee.

Magnet measurements

Guy continues, ‘When measuring the magnetic field strength, we not only recommend the correct flux density, cleaning and implementation are also important criteria. Take, for example, a situation in which there are no stainless steel pipes around the magnets (open-pole systems); they will rust, and bacteria will grow between the magnets. The performance is also affected by the distance between the bars. These are often placed farther apart to attain a large capacity.

This results in a gap in the magnetic field, making it impossible to capture all of the iron particles. To overcome this deficiency, I advocate including the minimum flux density in the HACCP specifications in the food industry. After all, it is the minimum flux density value that determines whether it is possible to capture an iron particle at all. ’

FEM-modelling-whitepaper.pdf

Need more information? Please use our contact form.