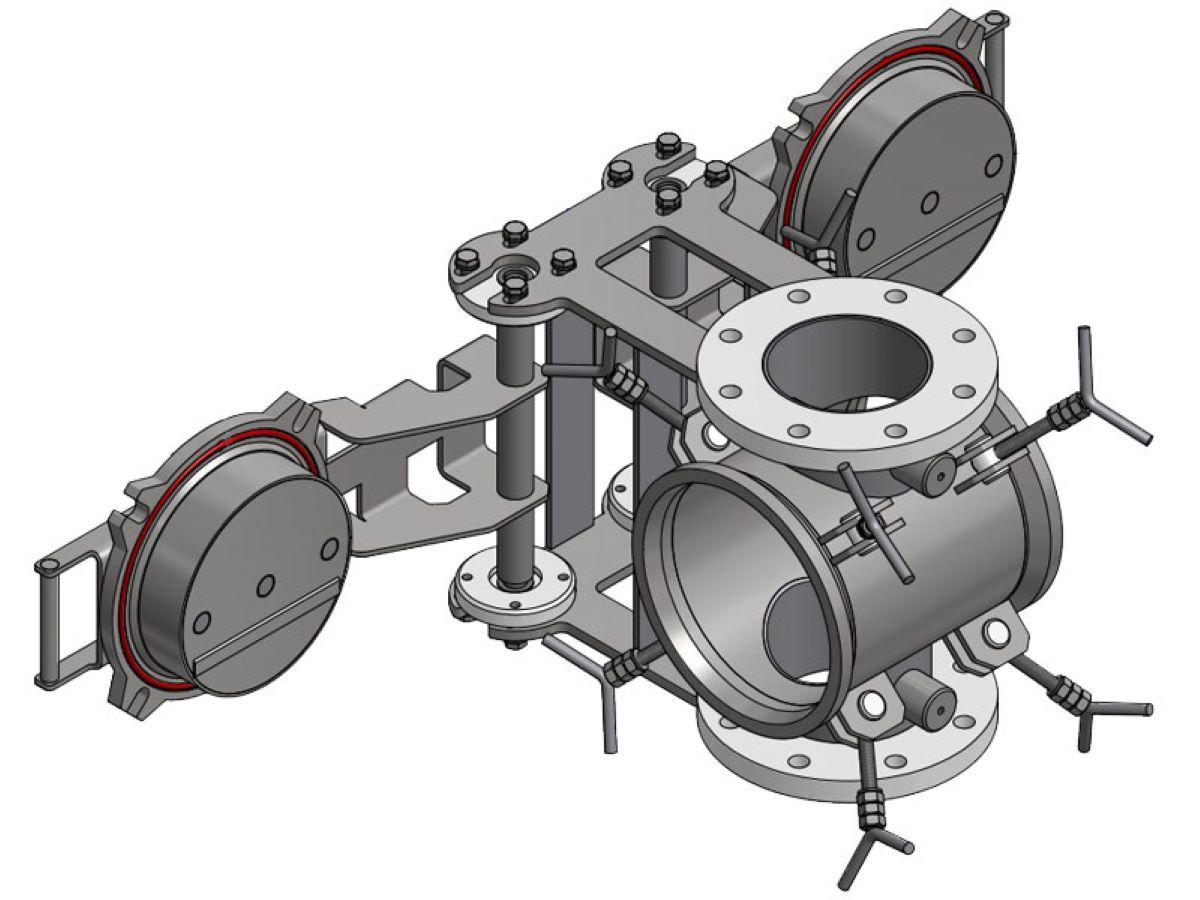

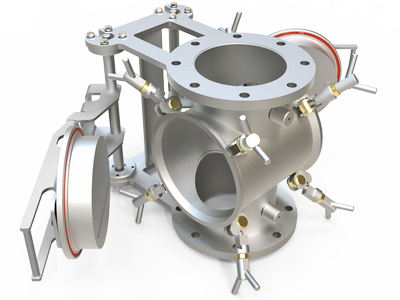

Magnetic filters - industrial - external pole

Very robust filter, suitable for filtering large ferrous contaminants of 1-50 mm out of coarse or high-capacity product flows under pressure, such as pulp in the paper industry. The magnets are placed on the outside of the product channel. Therefore the passage is completely free, enabling large parts to pass unobstructed.

- Manual cleaning (wipe off)

- Capture Fe particles from 1 - 50 mm

- Flanges DN100-250 (EN 1092-1)

- Max. 10 bar / 60 °C

- Plate magnets on side (6000 gauss)

High-capacity & coarse product flows

This very robust magnetic filter is designed especially for larger capacities and coarser product flows. An example of a common application is pulp in the paper industry.

Because the magnets are located outside the product stream, this filter permits better flow than filters with magnetic bars. However, the magnetic contact is less, so that only larger ferrous particles will be filtered out.

We can calculate the precise pressure drop with these filters in your situation for gaseous or liquid products using our FEM software. The pressure drop depends on the physical properties of your product flow (viscosity) and its speed. Please contact us about this.

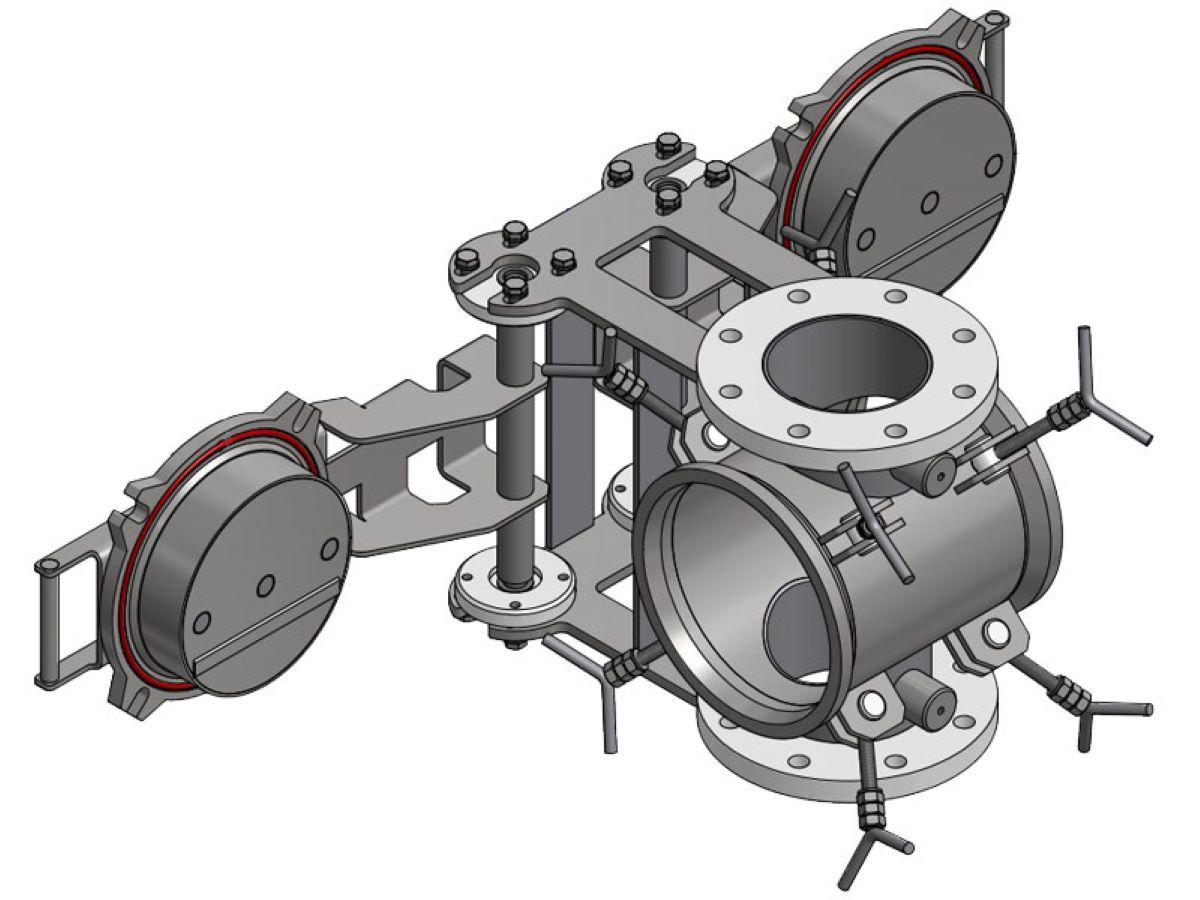

Construction & materials data

Click on a product variant to find the data sheet, drawings and other downloadable product information.

Short description

This industrial magnetic filter is equipped with plate magnets, placed on the sides of the product channel. This permits a better flow than filters with magnetic bars, because they are placed in the middle of the product flow.

- 2 Plate magnets outside product channel

- Magnet quality N-35, 6,000 gauss on the magnet contact surface

- Max. 10 bar / 60 °C

- Inlet/outlet DN100 - 250 (EN 1092-1 PN16)

- Finish: grit blasted

- Materials - in contact with product: AISI316(L)

- Material gaskets: Silicone acc. EC1935 / FDA

Available accessories & spare parts

Click on a product variant to find the online available accessories & spare parts.

Filtering & discharging of ferrous impurities

How does the magnetic filtering work?

2 strong neodymium plate magnets are positioned on the sides of the product channel. Here they attract passing ferromagnetic contaminants. The captured ferrous particles stick to the magnets, while the purified product flows further.

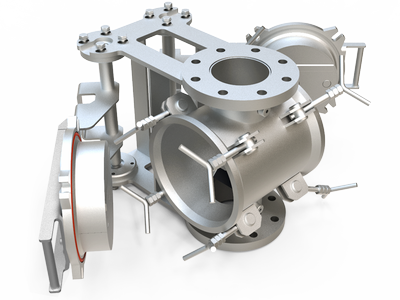

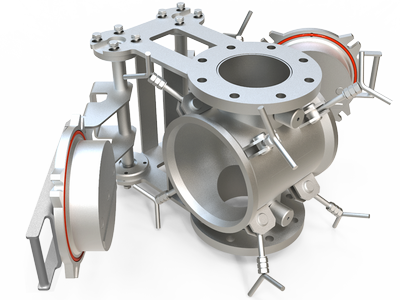

How does the cleaning / iron discharging work?

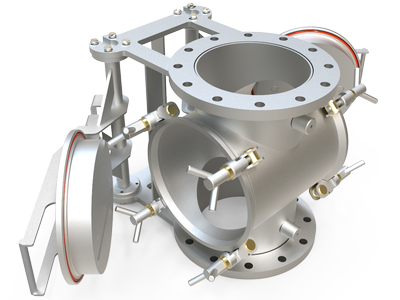

After the product stream is stopped, you swing the magnets outwards. Now wipe them clean by hand.

Cleaning / iron discharging sequence

- Stop the product flow.

- Loosen the srew connections of the magnet units.

- Swing the magnet units outwards as far as possible.

- Wipe clean the magnet with a soft cloth and - if necessary - a suitable cleaning fluid.

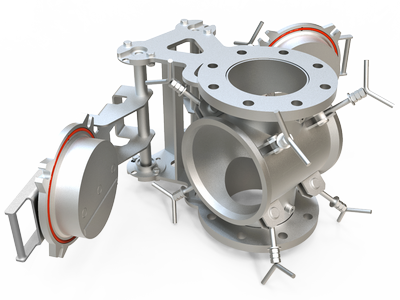

- Swing the magnet units back against the housing.

- Re-tighten the screw connections.

- Restart the product flow.