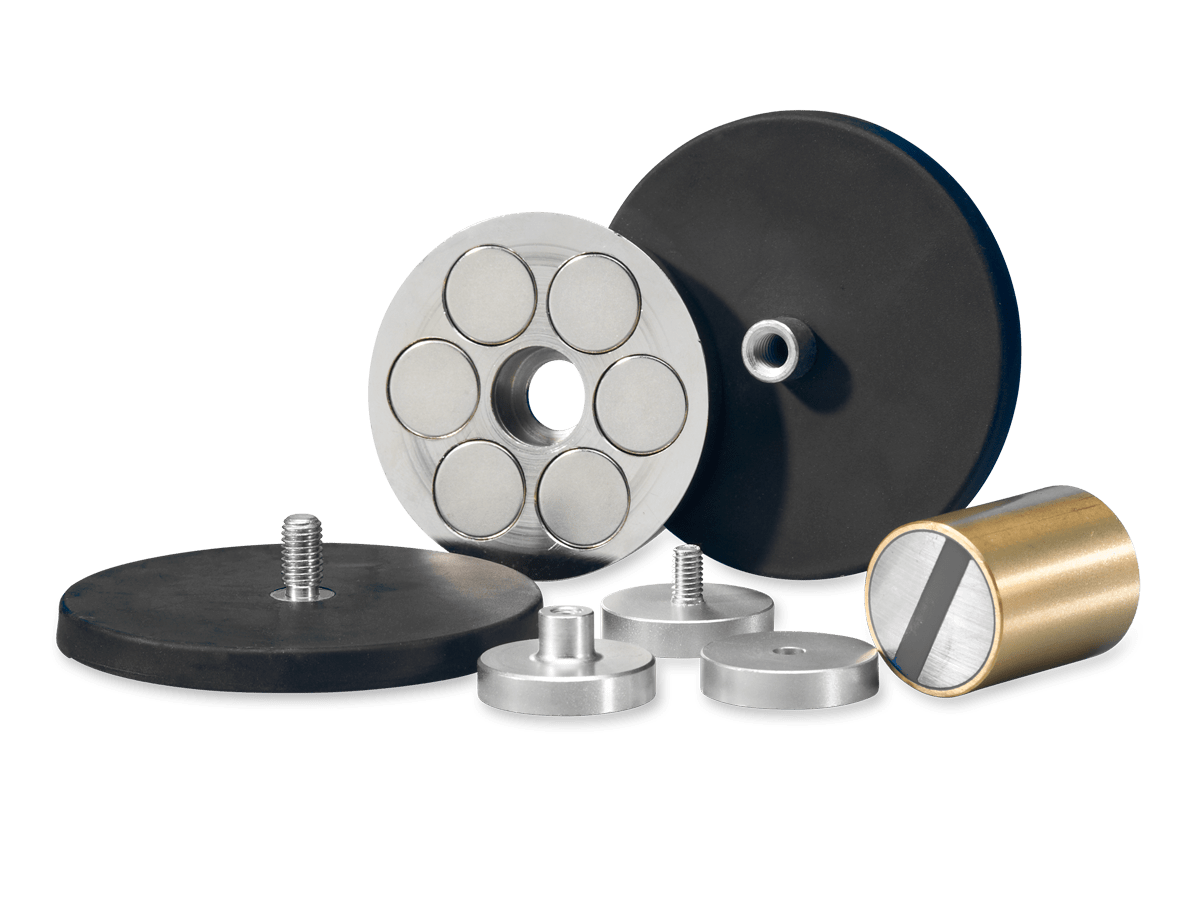

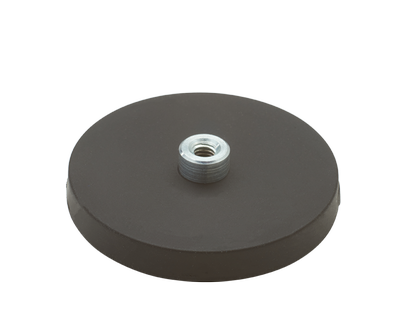

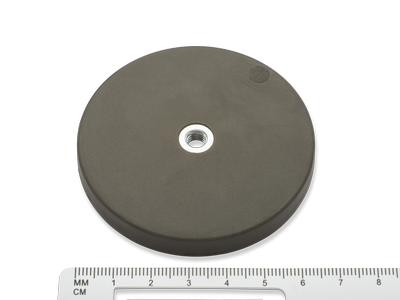

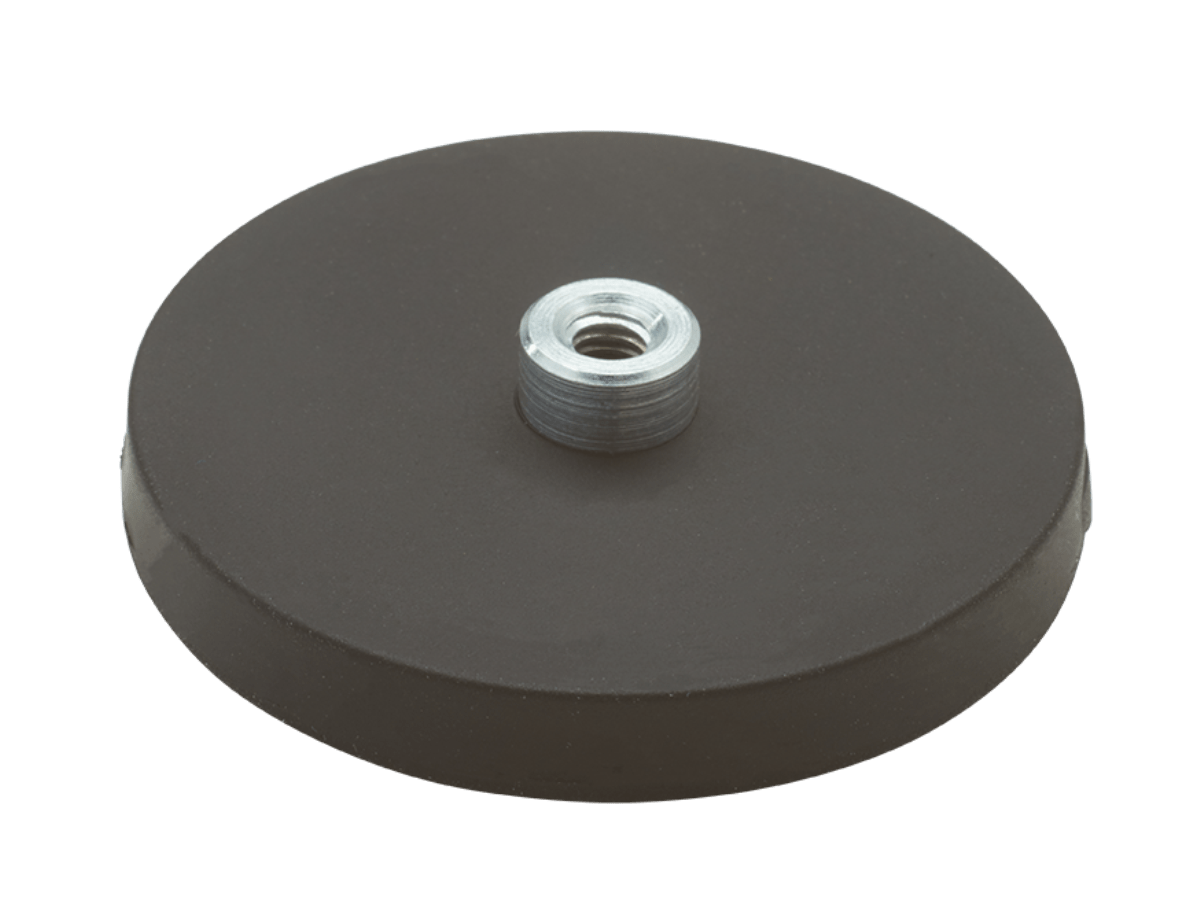

Rubberized pot magnets

Compact magnet systems with a steel shell and rubber coating for more shear force. Thanks to the shell of these magnet systems, the magnetic field strength increases and the pot magnets are more resistant to corrosion or chemicals. Pot magnets have a single attracting surface. This precludes dispersion of the magnetic field.

Rubber coated magnets are perfectly suited for easily damaged surfaces, to prevent scratches. Due to the powerful neodymium system, you can rest assured they will remain securely in place.

- Attach without drilling or screwing

- Moveable, reusable and non-scratch

- Deliverable from stock

- High shear force

- Buy magnets online

What does a neodymium pot magnet consist of?

These super-strong pot magnets are made of the alloy neodymium-iron-boron (NdFeB), which Goudsmit markets under the brand name Neoflux®. The shell or pot ensures magnetic shielding. The bonding surface has a rubber coating for a higher shear force and to prevent scratches.

When does loss of magnetic strength occur?

Neodymium rubber coated pot magnets have an operating temperature of up to 80 °C. When heated to this temperature, the magnet loses 15 to 20% of its magnetic strength. This is not permanent; the force is restored when the magnet returns to the normal ambient temperature.

External magnetic fields may also cause loss of magnetic force. An air gap or non-magnetic materials located between the magnet and workpiece reduce the tensile force.

Holding forces

The specified holding forces are measured under optimum conditions: perpendicular, on a piece of grade 37 steel that has been ground flat with a thickness of 5 mm, without air gap.