Challenges in cocoa processing

Both during the intake of raw cocoa beans and the processing into the final product, iron contamination is present in the product flow. This occurs during harvest, during packaging, transhipment and transport. But also in the production process of chocolate we see iron particles end up in the product through various processing steps.

Larger metal particles between cocoa beans cause significant damage to machines, mills and presses, resulting in costly production downtime. But small metal particles are also extremely undesirable in the final chocolate.

Raw cocoa beans and cocoa powder always contain iron particles

Strong magnetic separators for separating coarse and fine iron particles from cocoa

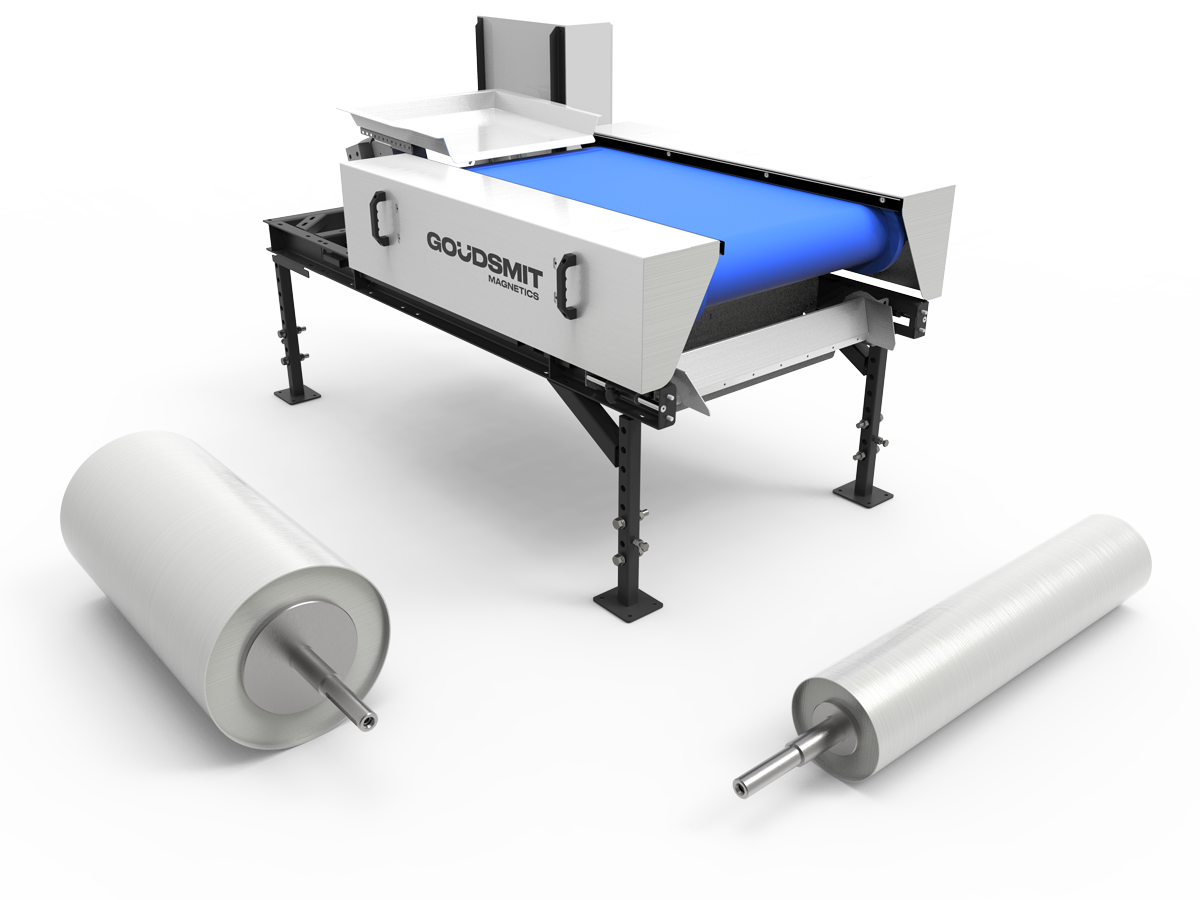

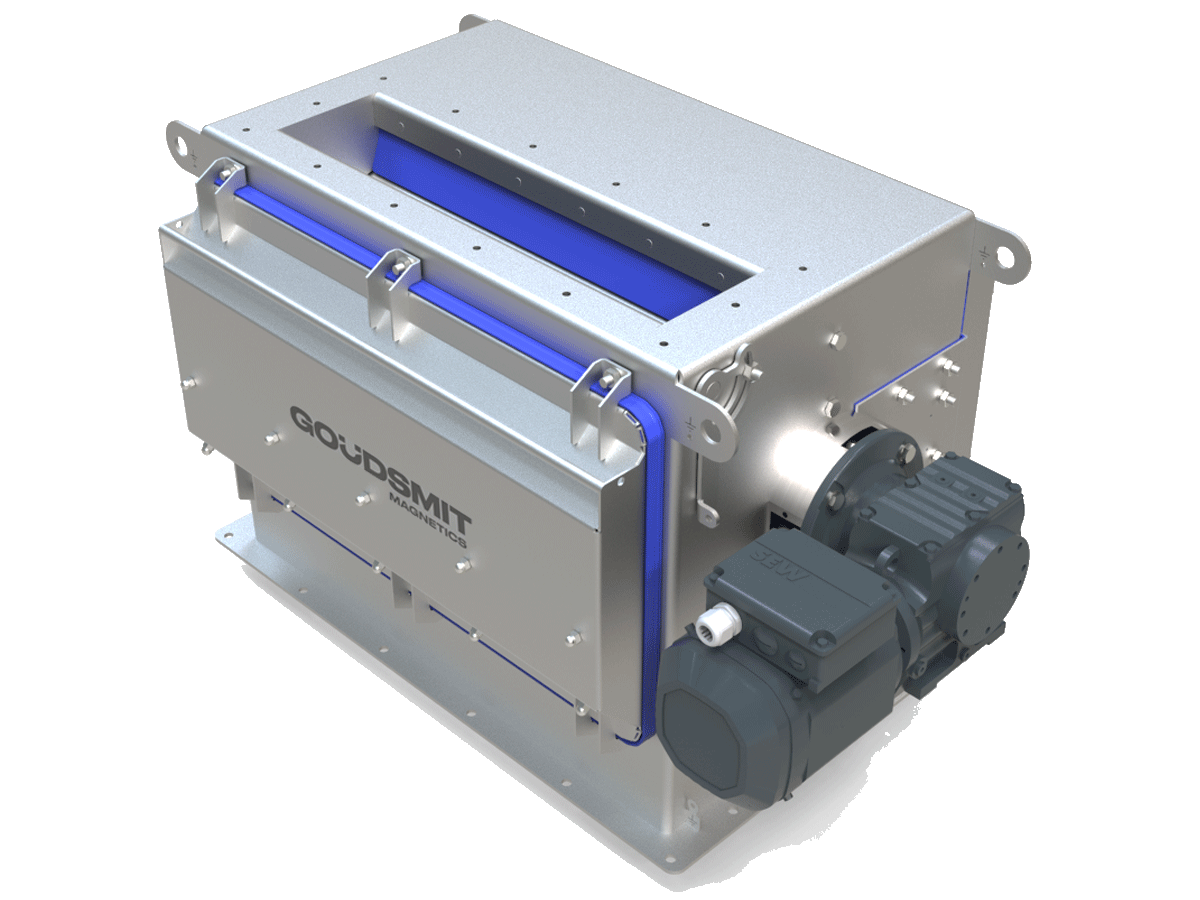

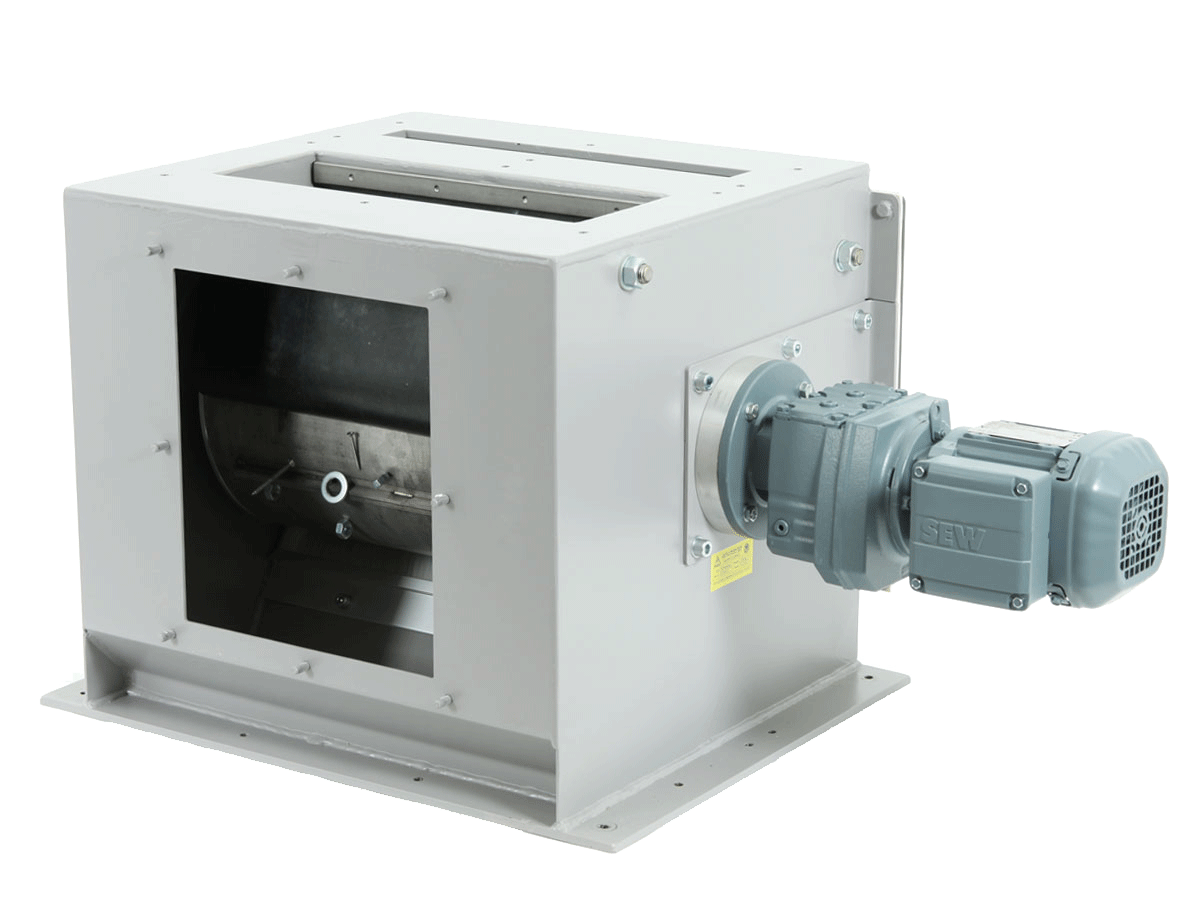

The metal particles in cocoa beans and powder vary in amount, shape and size. To be able to magnetically separate these parts, we use different magnetic separators. There is a lot of iron in the intake of bean unloading. During this phase, magnetic drum separators remove the unwanted, larger iron particles from the bulk flow of beans.

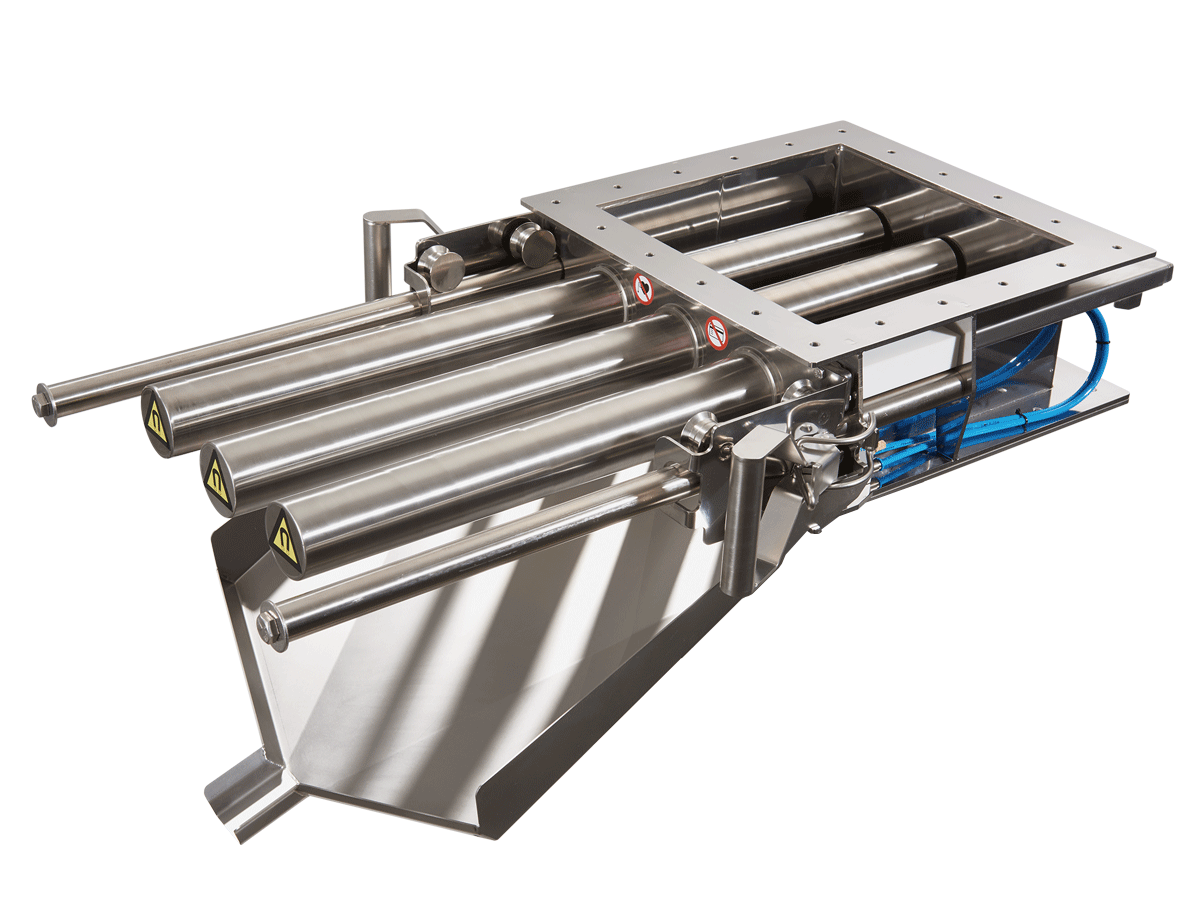

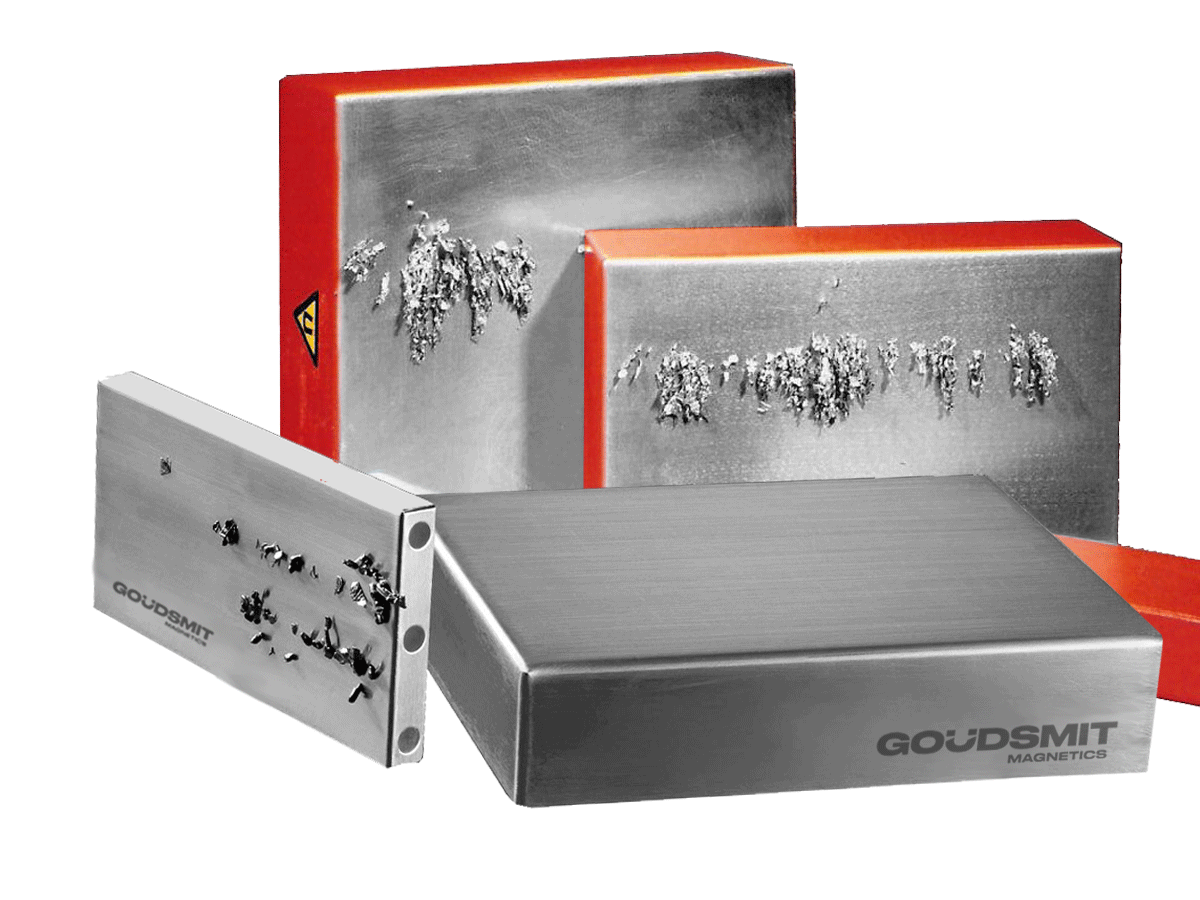

Further on in the process, where increasingly less iron is present, other types of magnetic separators are suitable. For example, during the processing step where the cocoa beans are unshelled. For this we offer powerful cascade, plate or external pole magnets that have been specially developed to capture this type of iron particles.

Drum magnetic separator - continuous automatic cleaning

Iron capture in the powder line

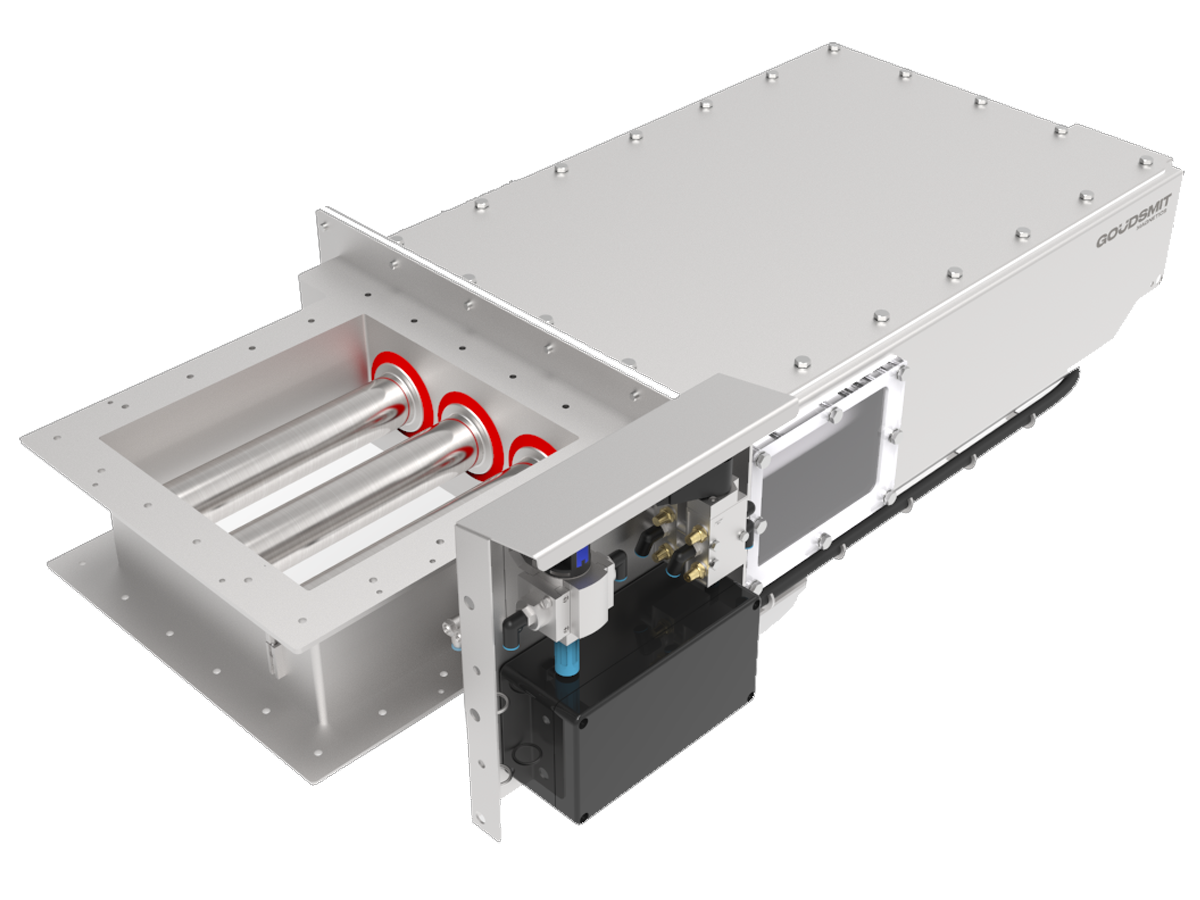

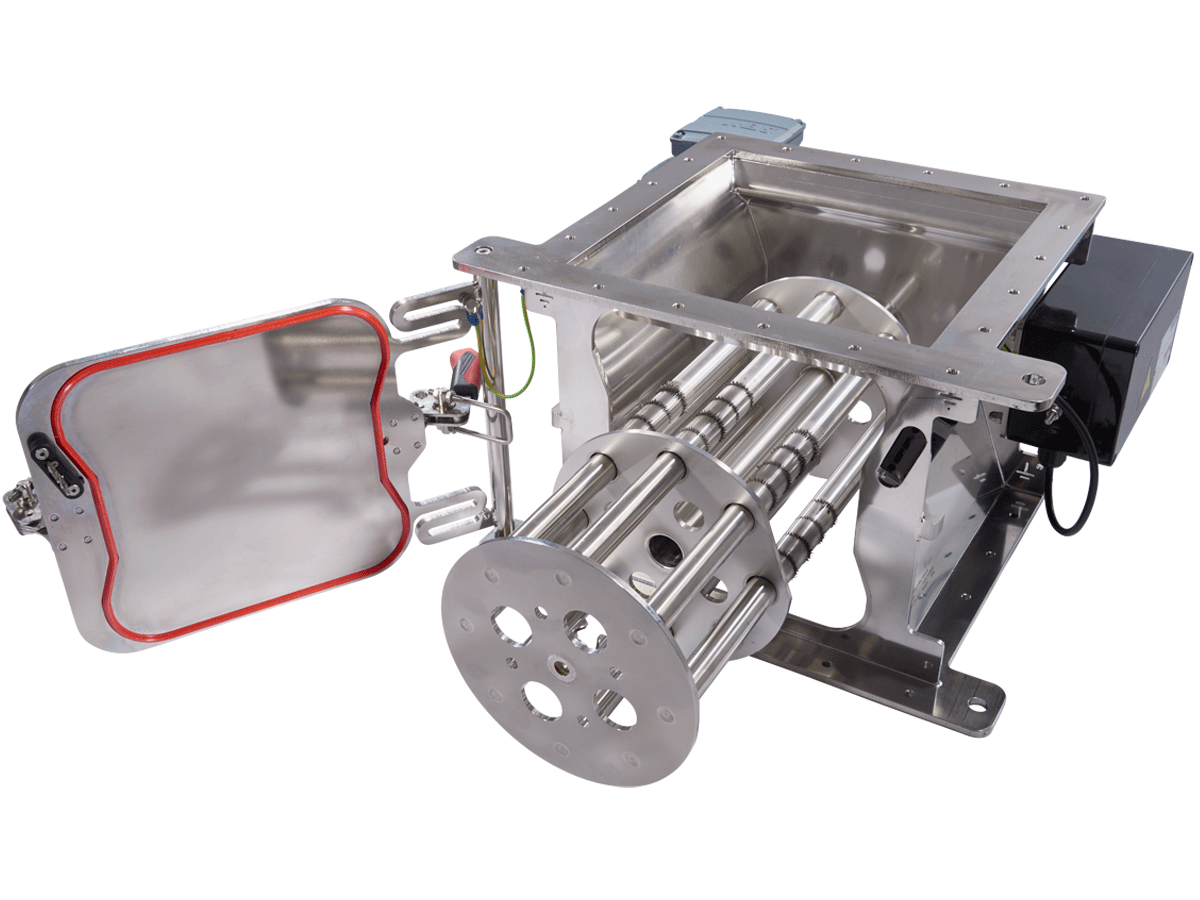

In the powder line, external pole magnets capture the unwanted iron particles most effectively from the product flow. These magnets are also very suitable for the cake dump, after the cocoa has been pressed and when the large pieces of cake come out of the press. Easy Cleanflow magnets remove iron particles after grinding the cocoa cake. The magnet choice depends on the particle size of the undesirable iron particles. We are happy to advise you on the possibilities.

Powerful magnetic separators also remove fine iron particles from fatty powders

Magnetic final inspection of the cocoa powder

During final inspection of the cocoa powder we use rotating Cleanflow magnets. The rotating movement of the magnetic bars ensures that the greasy cocoa powder does not accumulate or remain stuck to the bars. This way the flow remains consistent and the capacity of your line is maintained. Ultimately, these magnet separators guarantee the quality of your end product and protect your reputation against iron contamination in the end product.

Magnetic final check to separate the last micro iron particles

Remove unwanted iron from liquid chocolate

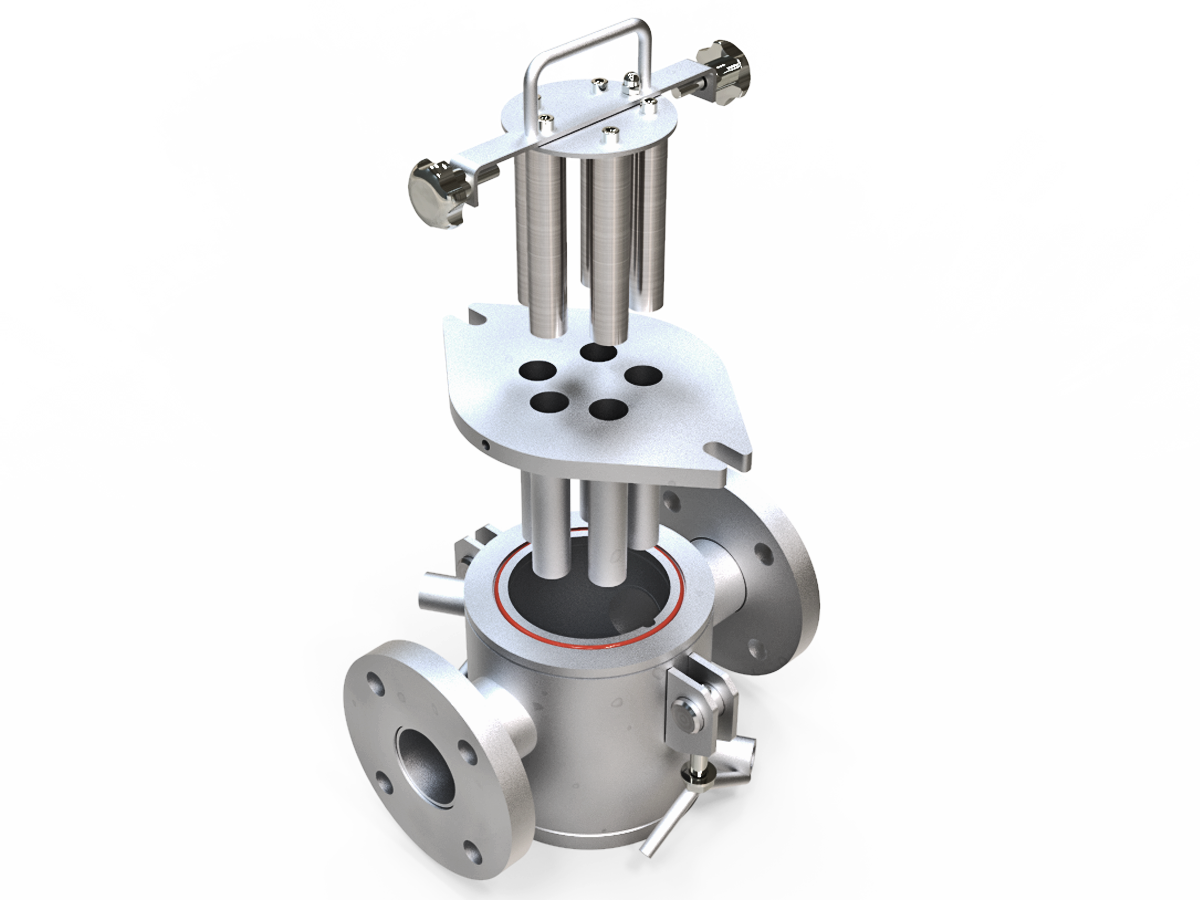

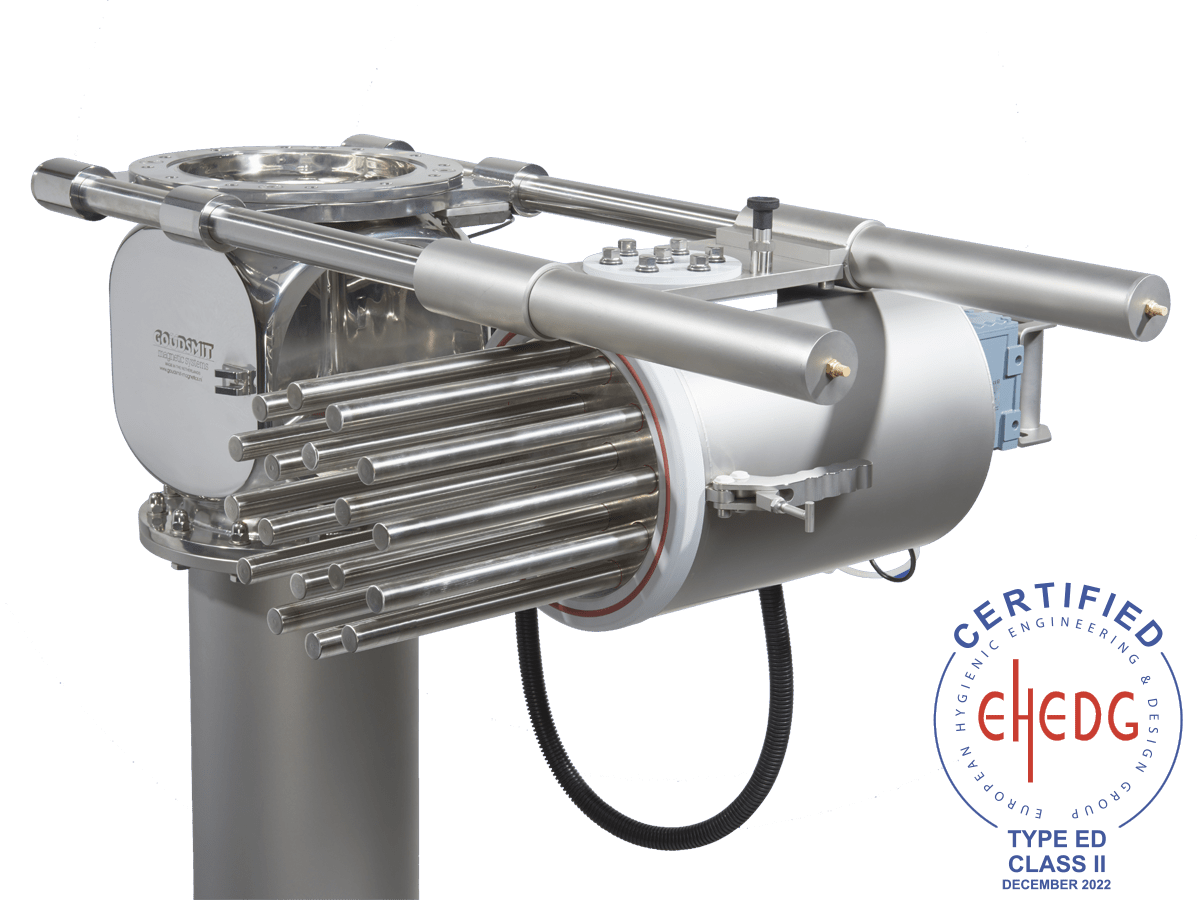

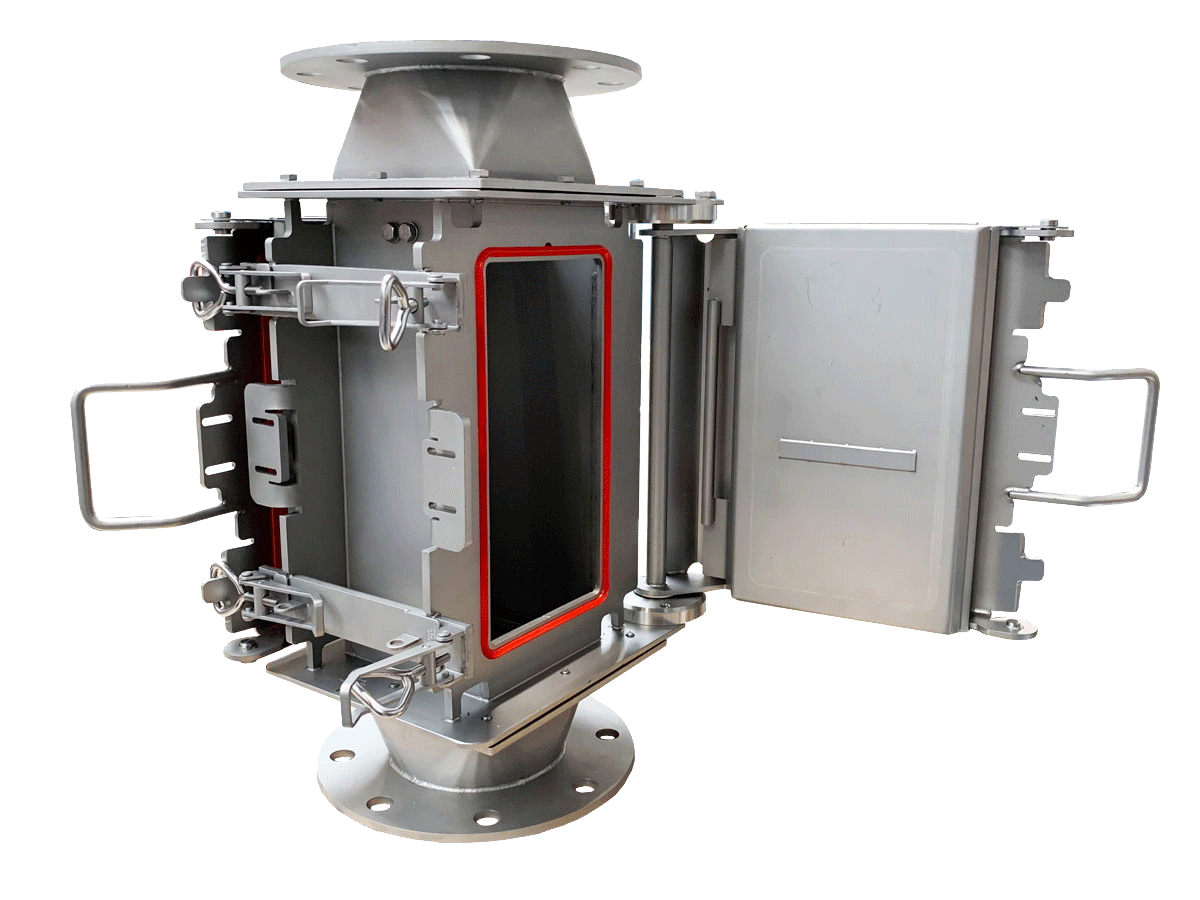

Special double-walled magnetic filters are the solution for separating very small iron particles from cocoa in liquid form, such as cocoa mass or chocolate. These filters are designed to operate under pressure. The double wall allows you to heat the housing with liquid. This prevents the liquid chocolate from solidifying.

These filters can optionally be equipped with a sieve with various mesh sizes to also filter out non-magnetic parts.

Custom advice: the right magnet in the right place

At Goudsmit, we always strive for the best separation result. By using different magnetic solutions in succession. Or by filtering the metal particles at different stages of the process. If magnetic technology is not enough, we will also tell you.

We often see differences in various product flows, also in the chocolate industry. In order to guarantee the correct degree of separation, we can determine and test the properties of your product in our extensive test centre. Practical tests give you and us quick insight to determine the right separator and location in the process. We will gladly advise you after an analysis of your situation. This way, you are guaranteed the best metal separation and product quality.

Chocolate processing plant