Sugar beet

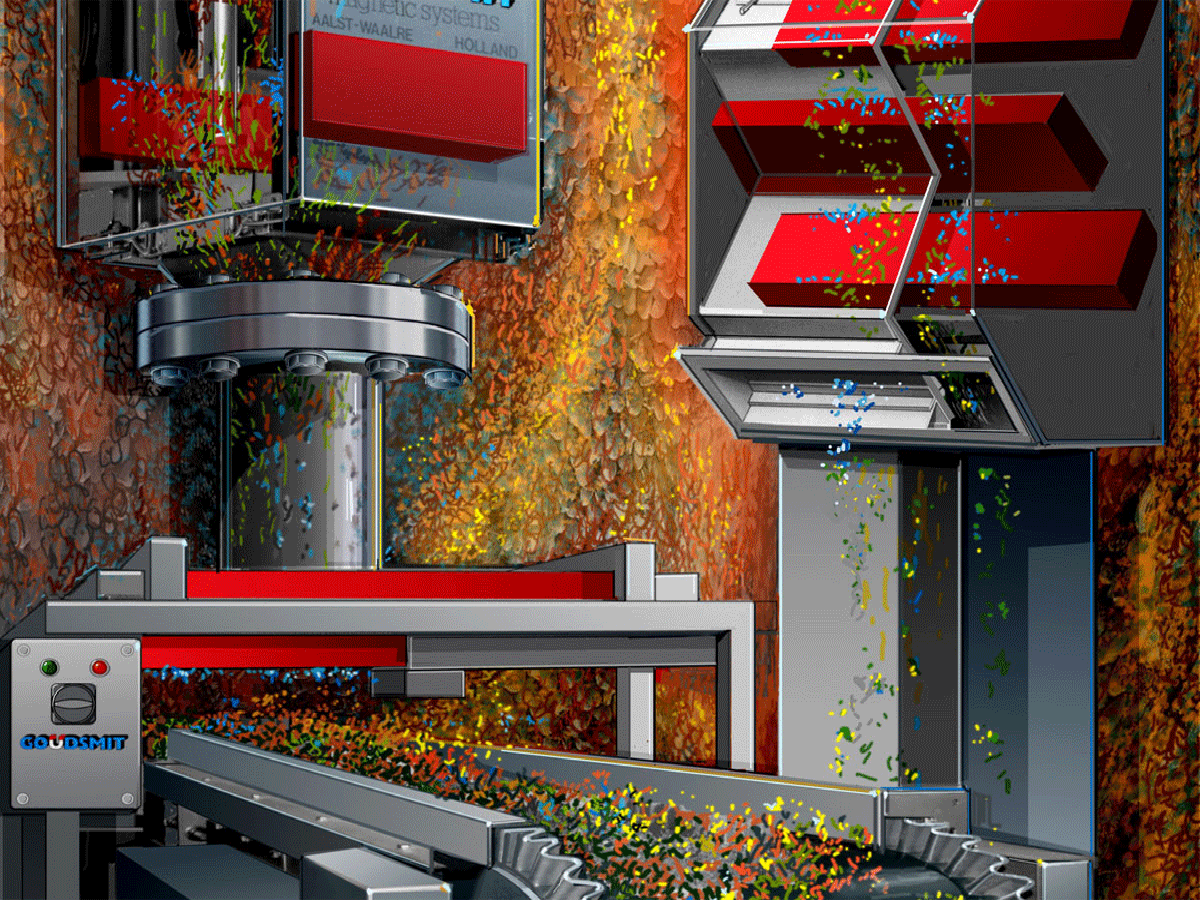

Sugar beet often contains pieces of iron and stainless steel, or even whole pieces of steel, after the mechanical harvest. This comes from the ground or harvesting machine and tool parts.

These cause major damage to the machinery, such as crushers and grinding mills that get stuck or broken. This results in costly production downtime.

To prevent this during this phase, we use large magnet systems such as overband magnets and block magnets before the processing continues.

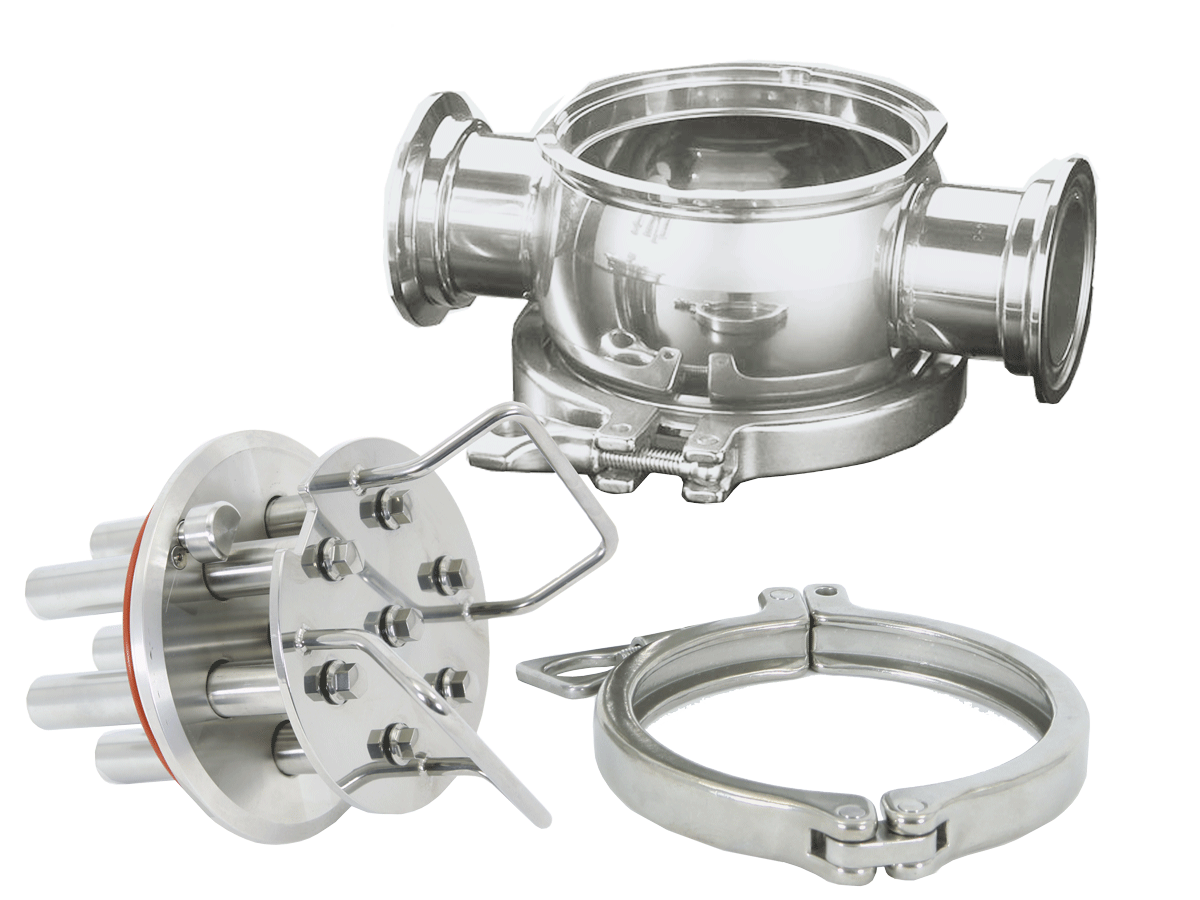

Plate magnets applications in pipe and belt transport

Wear and tear of machines

Machine wear also occurs during the follow-up process in sugar production. The result is that iron grindings remain in the sugar.

This is on top of the metal contamination that occurs in the event of damage to bearings, conveyor screws and pumps.

Magnets remove this contamination during the process. In addition to preventing damage to machines or filtering iron contamination from sugar, magnets are also a good indicator of problems with the machinery.

Magnetic inspection rod with iron contaminants in sugar

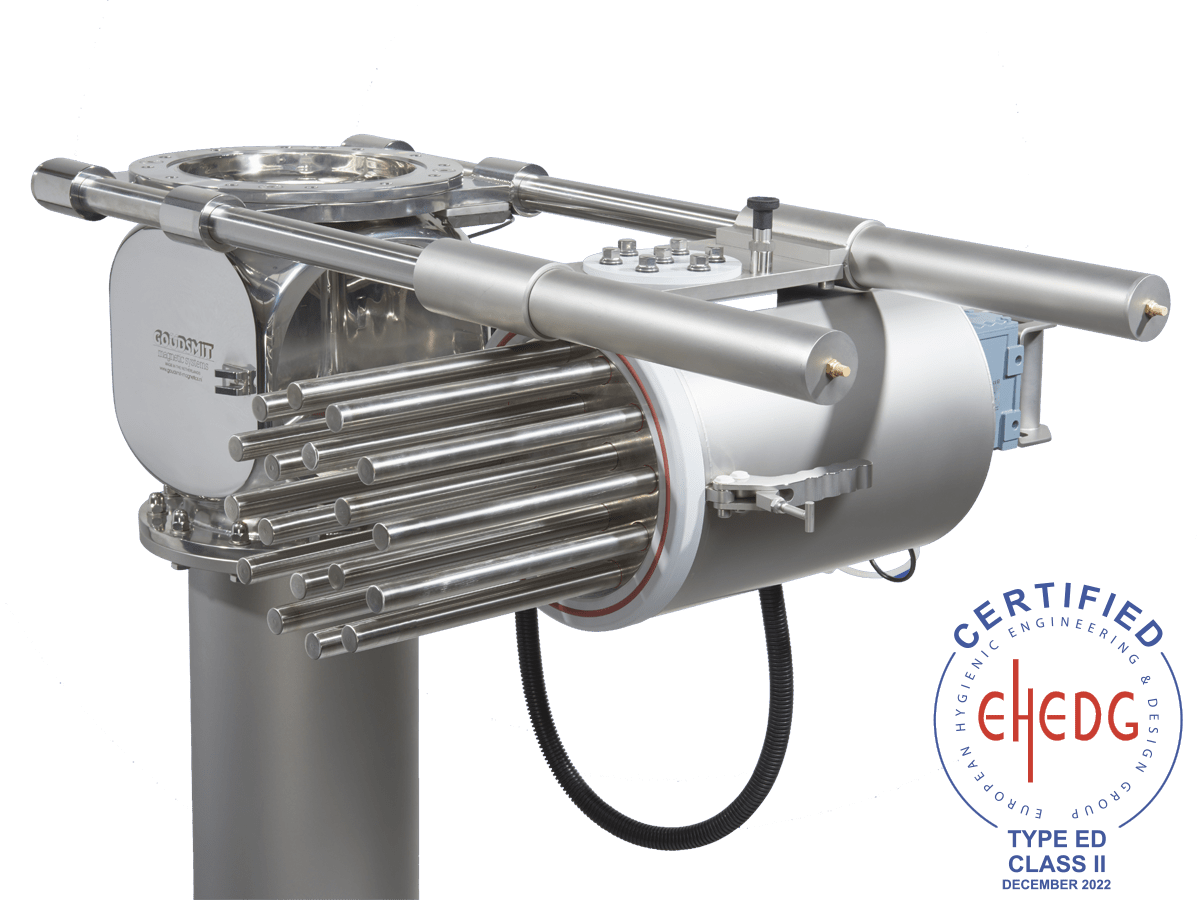

Fine metal particles

Metal contamination remains a risk throughout the entire production process. But a pure end product is important.

The further along the sugar processing takes place in the production process, the finer the metal particles to be removed.

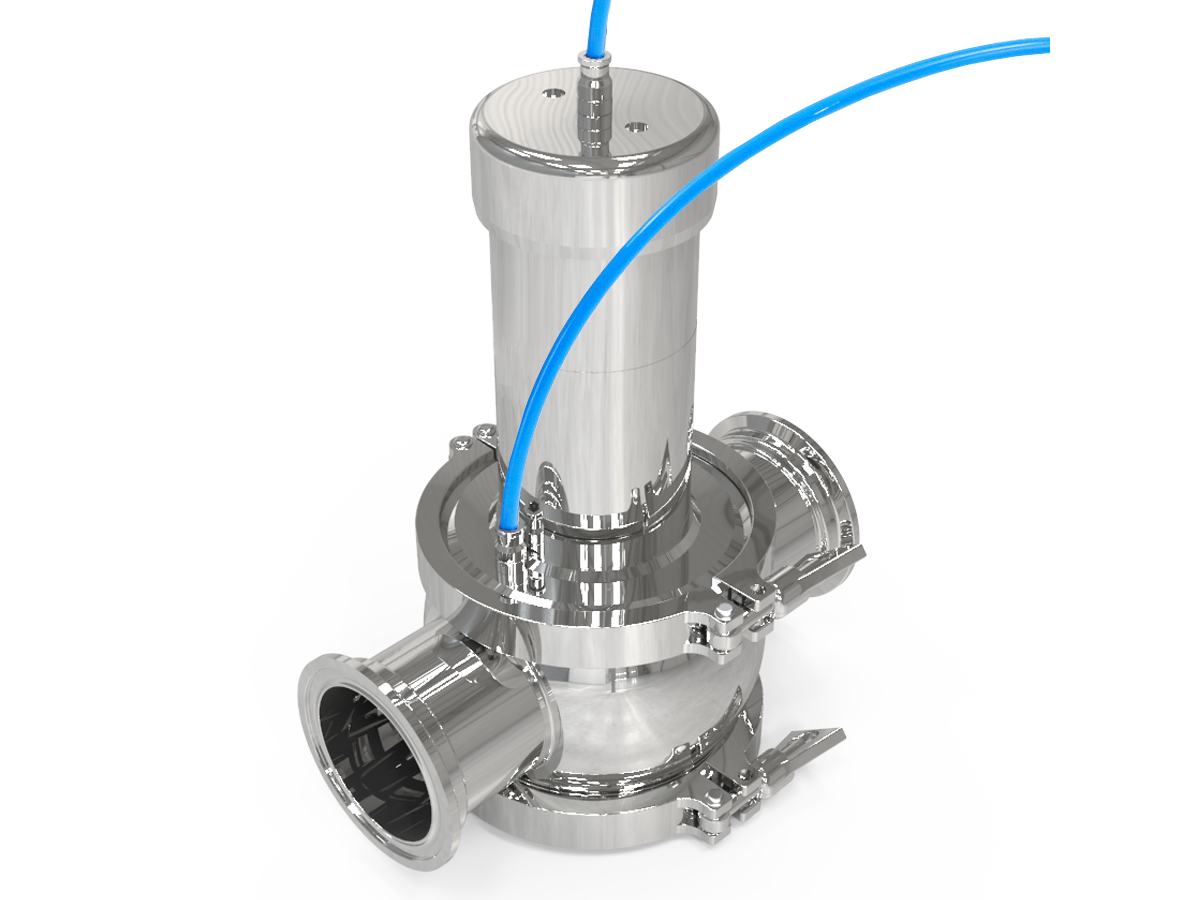

Strong Cleanflow magnets are the solution. They remove iron particles of only a few microns, with production continuing even during cleaning.

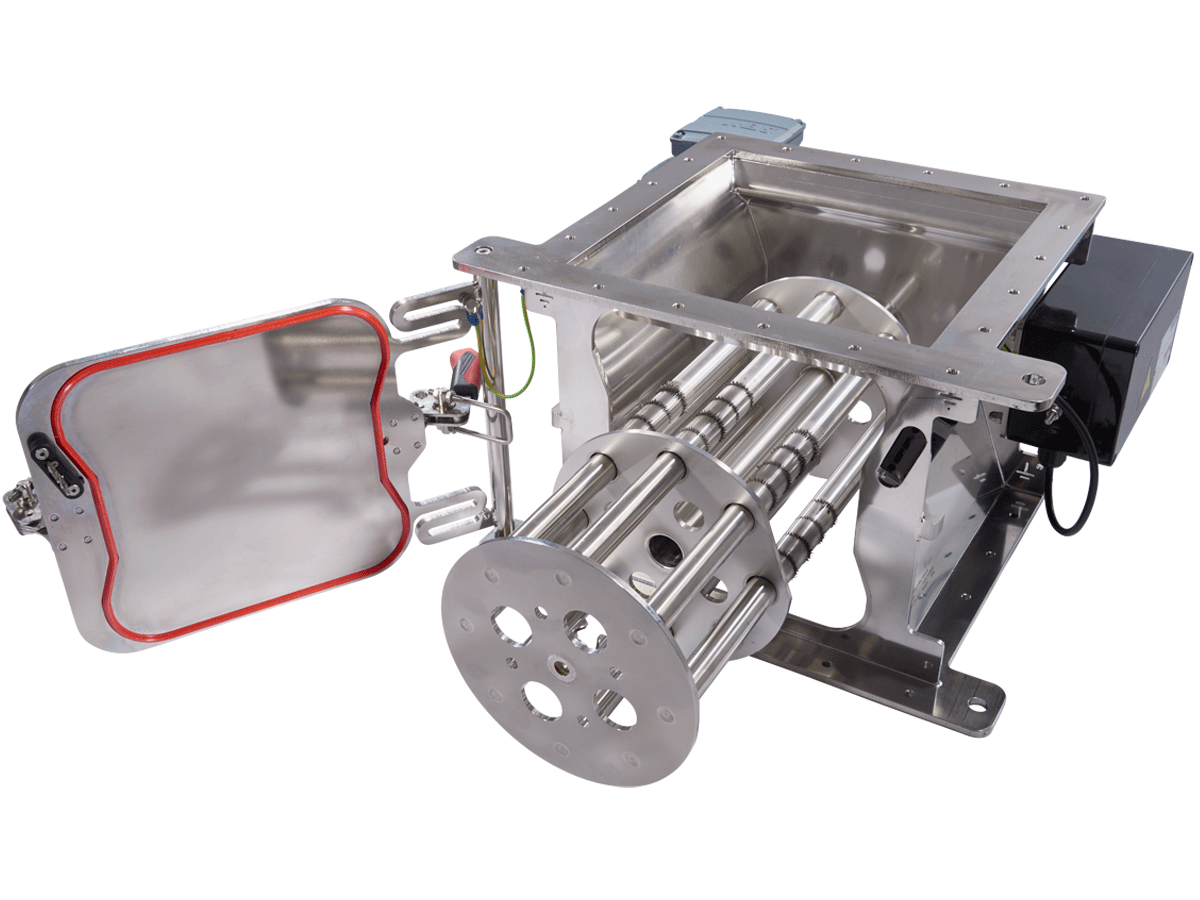

A magnet for every process

Depending on the types of sugar, we can apply static or rotating magnet systems: for smoothly flowing granulated sugar, a static catching magnet is sufficient, while for finer, sticky icing sugar, we use rotating magnets.

For pneumatic transport systems (overpressure or underpressure), we use powerful magnetic filters.