About magnetic separation & filtering

Information on metal contaminant separation with magnetic filters.

Magnetic separator vs metal detector

When do you need a magnetic separator and when do you need a metal detector?

A magnetic separator filters metal contaminants from the product flow and removes them.

- practically no product loss

- suitable for removing both sporadic and common metal pollution

A metal detector only detects. If you want to remove the metal particle, the production line has to be stopped, or the metal particle has to be ejected by a rejection mechanism.

- a lot of product loss

- mainly suitable as a means of inspection for sporadically occurring metal contaminations

Magnetic separator types

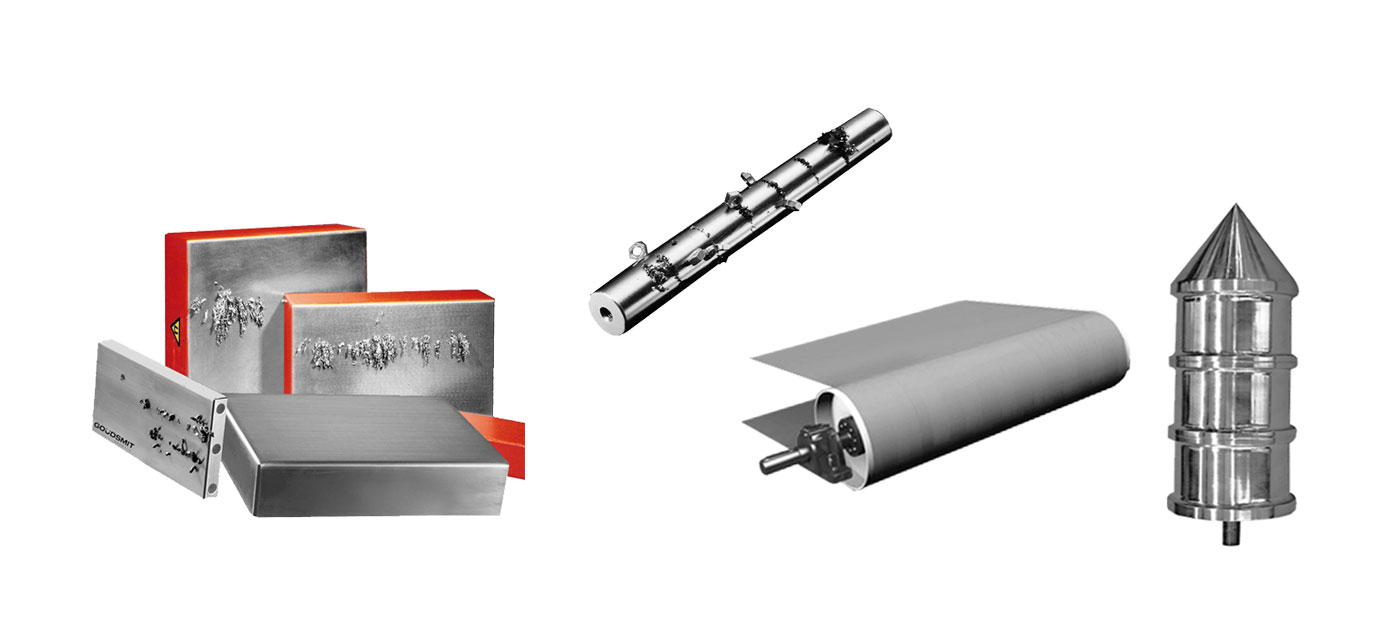

4 magnet systems with specific properties:

1. Magnetic separator with magnetic plates

The plate magnets are mounted on the outside of the pipe channel. Plate magnets and chute magnets are used in pipeline transport. These systems are always permanently magnetic.

2. Magnetic separator with suspension magnets

Suspension magnets are large block magnets without or with a band system (overband magnets). They pull metal parts from a material flow on a passing belt. Very suitable for magnetic recycling & sorting. These systems are permanently magnetic or electromagnetic.

Magnetic separators with plate or block magnets have a deeply penetrating magnetic field for capturing ferromagnetic metal particles as small as 1 mm.

3. Magnetic separators with magnetic bars

Magnetic separators with magnetic bars have an extremely powerful yet less deeply penetrating magnetic field. By placing them in the product channel, they make direct contact with the passing product. Magnetic bar separators are therefore best suited for trapping small ferrous contaminants as small as 30 µm and even weakly magnetic contaminants such as processed stainless steel from bulk flows in filling openings and pipelines.

Magnetic grids, Cleanflow magnets and magnetic filters make use of magnetic bars.

4. Magnetic separators with cylindrical magnets

Cylindrical magnets are usually found in separators that directly and automatically remove the captured metals. They are therefore capable of separating or sorting large quantities of metal contaminations.

You will find them in:

- Recycling & sorting applications:

· robust types of drum magnets

· magnetic head pulleys

· eddy current separators - Filter applications:

· bullet magnets

· drum magnets

Magnetic separator options

Magnetic separators come in many versions and with many options.

This means that there is almost always a suitable product for your metal issue. If you cannot find the right solution, our engineers can assist you.

1. Food/Pharma

- Magnetic filters that meet the strict European foodstuffs directive EC 1935/2004 and the EHEDG guidelines

- Magnetic filters suitable for Cleaning in Place (CIP)

2. Dust explosion-proof

For dust explosion risk areas: ATEX-certified magnetic separators.

3. Finish

- painting (only for products that are not made entirely of stainless steel)

- abrasive grit blasting – Ra 3 µm (standard - non-food/pharma finish)

- drum polishing / hand polishing – Ra ≤ 0.4 µm (standard food/pharma finish)

- electrolytic polishing - Ra ≤ 0.6 µm (less attractive, not always possible due to shape)

- wet blasting – Ra ≤ 0.6 µm (new – better resistance to powder adhesion than polishing)

4. Cleaning/removal of trapped metal particles

Bar and plate magnet systems

- manual cleaning: manually wiping off iron

- manual quick cleaning: with extractor, iron falls off after moving the extractor plate away from the magnet

Bar magnet systems

- easy cleaning = semi-automatic cleaning: manual action triggers automatic cleaning cycle

- automatic cleaning with production stop / filters with CIP cleaning

- automatic cleaning without production stop

Drum magnets and belt separators (mostly recycling & sorting)

- automatic, continuous cleaning without production stop

5. Magnet material choice: strength and temperature resistance

Most separators contain very powerful neodymium magnets. Sometimes separation with cheaper ferrite magnets - or a combination - is sufficient.

- Neodymium magnets are the strongest magnets on the market. This makes it possible to filter out small and weakly magnetic parts.

The downside of neodymium is that the standard versions can only withstand temperatures of up to 60°C. - Ferrite magnets are around 10x less strong than neodymium magnets, but cheaper and suitable for high temperatures (up to around 200°C).

For high temperatures and high magnetic holding power you can opt for:

- Temperature-resistant neodymium magnets: up to 250°C.

- Samarium cobalt magnets: up to 350°C.

6. Coating or hardening – for abrasive product streams

For abrasive bulk stream applications, the magnets and possibly other contact parts are given a wear-resistant finish.

For industrial applications, this is often a tungsten carbide coating. Another option is hard inchromizing, also when a hygienic finish is desired.

7. Control

Most magnetic separators can be fitted with safety sensors to detect whether they are closed. If necessary, with a detection that checks whether the magnets are in the product channel when you start production.

Automatic cleaning systems have simple controls. You can integrate these into your system so you can control the cleaning from your control room. Some systems have a PLC control so that they can be operated from the control room and directly from the machine.

Types of metal pollution

Most metal pollution is magnetically attractable or repellent.

There are three types of metal pollution:

- Iron and steel particles (ferrous metals). Through the ferritic or martensitic structure they have a high relative magnetic permeability, making them strongly magnetic. These particles are powerfully drawn to magnets.

- Stainless steel contaminants. These are often wear particles from your production line. Stainless steel has a structure that, in principle, is not attracted to magnets. Mechanically processed or deformed stainless steel, such as a wear particle, is, however, magnetic because the structure changes. With the strongest magnets we can now often also filter these weakly magnetic stainless steel particles from your product stream.

- Non-ferrous metals, such as aluminium and copper. These are not magnetic and are therefore not attracted by a magnet. However, you can often separate these metals magnetically with eddy current separators.