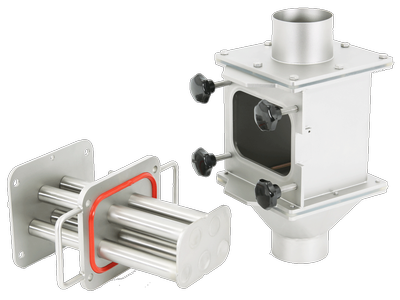

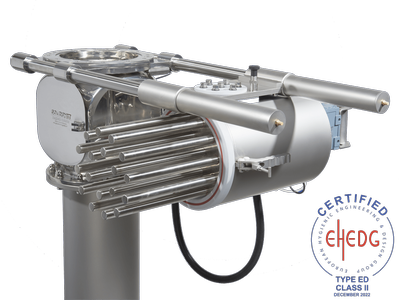

Cleanflow drawer magnets

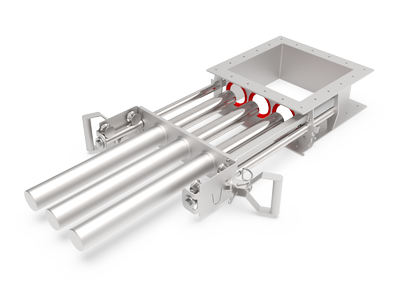

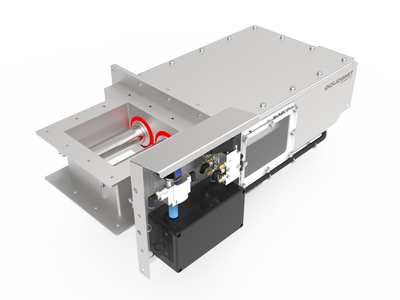

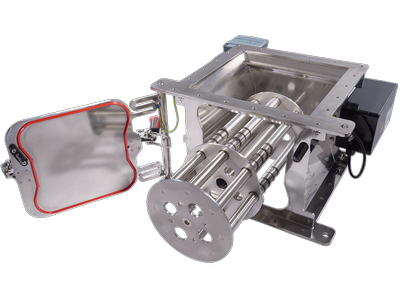

Goudsmit Cleanflow drawer magnets are magnetic grid separators in a housing, equipped with strong neodymium magnetic bars. They filter small ferrous contaminants from powders and granulates in free-fall and low-pressure transport pipes. Because the magnetic bars are placed inside the product flow, optimal magnetic contact and optimal removal of ferrous contamination is achieved.

Possible applications: plastics, food products, pharmaceutical and ceramic industries.

- Optimal magnet contact

- Capture Fe and weakly magnetic particles from 30 µm

- Max. particle size 10 mm

- Types basic/food/pharma

- With neodymium magnetic bars