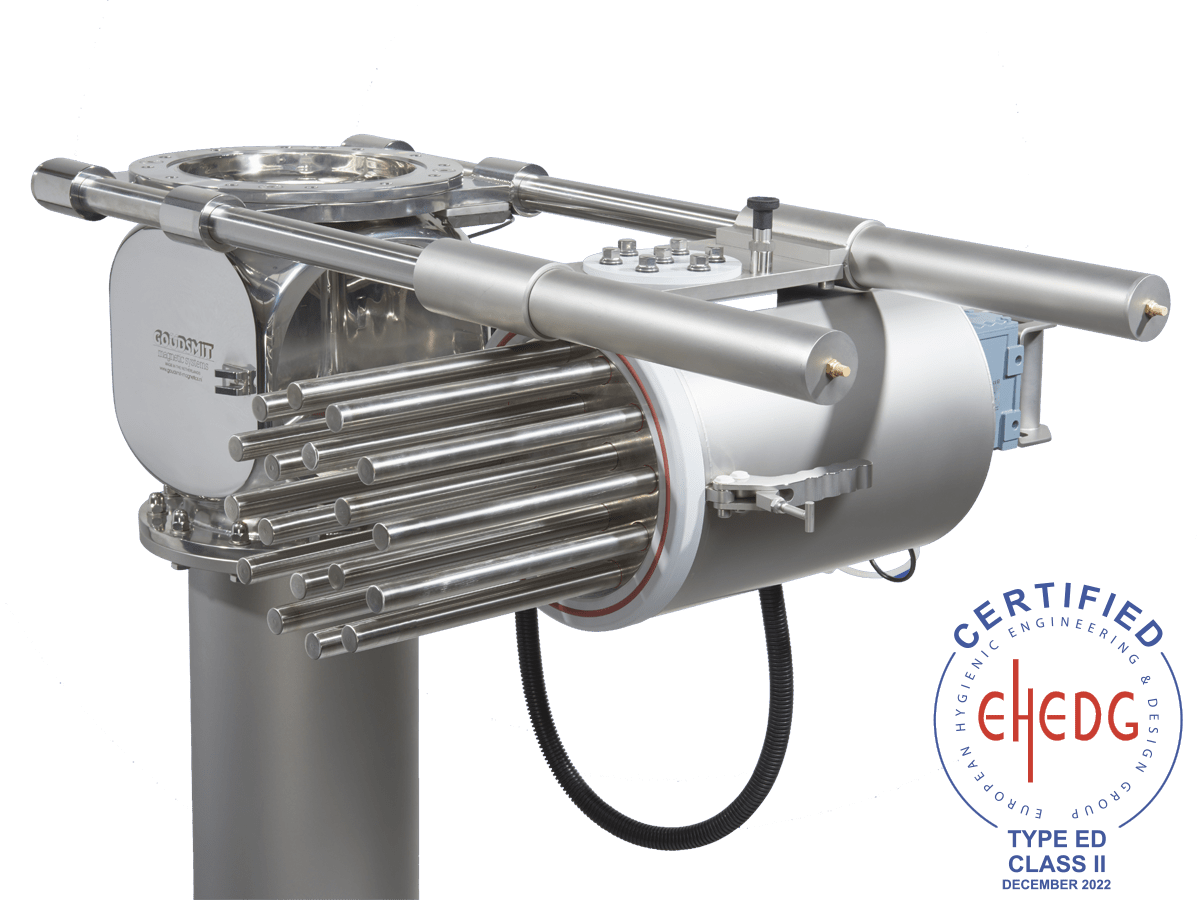

Cleanflows - semi-automatic cleaning - rotating (EHEDG)

This hygienic Cleanflow magnetic separator - type 'Hydrohansu' - is the only Cleanflow to have EHEDG certification. It has a hydroformed, polished housing without reclining surfaces and blind spots.

Designed for the magnetic filtering of small amounts of ferrous contaminants from poorly flowing food and pharma powders with a high risk of bacterial growth. Rotating the magnetic bars prevents bridging and blockages.

- Semi-automatic cleaning

- EHEDG certified hydroformed housing

- Rotor with magnetic bars

- Magnetic bars in pneumatic tube (Ø25 mm, 11,000 gauss)

- Atex II 1/3 D

Filtering of ferrous contaminants from poorly flowing Food/Pharma powders

The rotating Cleanflow magnetic separators are specially suited for poorly flowing powders, because the rotation prevents bridging and blockages. See also 'Working principle'.

This 'Hydrohansu' type is the only rotating Cleanflow to be EHEDG-certified, and thus meets the most stringent requirements in the pharmaceutical and food industries. It has a smoothly polished hydroformed housing, free from horizontal surfaces or sharp/dead corners. This greatly reduces the risk of bacterial growth.

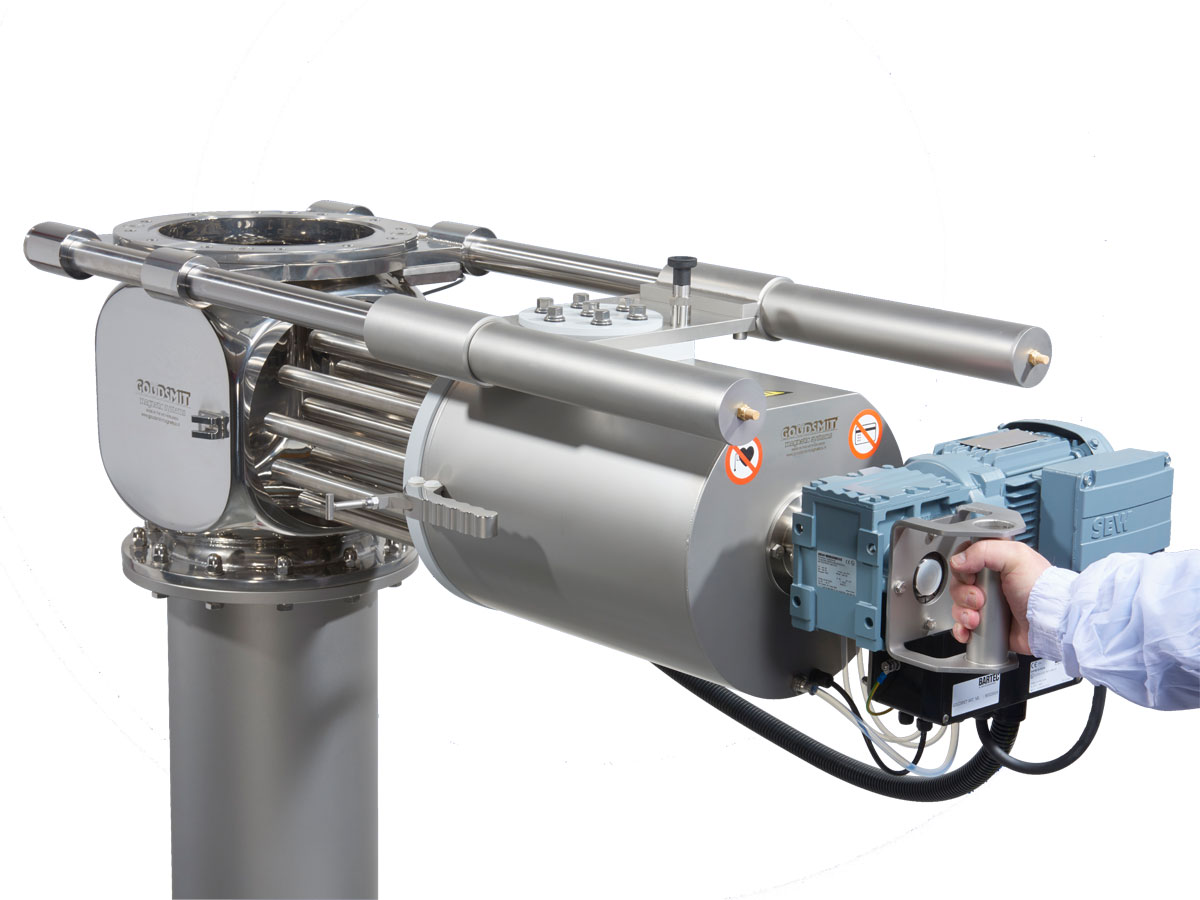

The Hydrohansu magnetic filter is cleaned semi-automatically. You manually pull the magnetic rotor out of the product channel over a guide. The magnets are thencleaned automatically.

Construction & materials data

Click on a product variant to find its data sheet, drawings and other downloadable product information.

Summary of important specifications

- Multiple pneumatically cleaning magnetic bars Ø25 mm mounted in a rotor.

- The entire rotor – including the drive motor – can be manually slid out over a robust guide.

- Magnet quality: neodymium N-52, 11,400 gauss on the Ø25 tube.

- Materials housing + rotor: AISI316(L).

- Rotor mounted in hydroformed, completely smoothly polished housing.

- Door gasket silicone EC1935 / FDA.

- Robust, hygienic quick-release clamp for closing separator.

- Schmersal safety switch - monitors whether the separator is closed and switches the motor on/off when the door is closed/opened.

- Detection switches check for the presence of the magnets in the product channel so that production can be started again safely after a cleaning cycle.

Accessories & spare parts

Click on a product variant to find the online available accessories & spare parts.

Filtering & discharging of ferrous impurities

How does the magnetic filtering work?

The rotor with very strong neodymium magnetic bars is positioned in the middle of the product flow. The product with ferrous impurities passes several magnetic bars while flowing through the separator.

The magnets attract passing ferromagnetic contaminants. The captured particles stick to the magnets, while the purified product flows further.

Because the rotor rotates inside the housing, the product continuously falls off the bars. This prevents 'bridging', product accumulation and ultimately blockages. Moreover, the magnetic filtering capacity remains optimal, because the magnetic bars remain clean.

How does the cleaning / iron discharging work?

Each magnetic bar has a magnet package that pneumatically moves inside a closed tube, thus automatically discharging trapped ferrous particles.

During a cleaning cycle, first manually pull the rotor out of the product channel. Then rotate the rotor 90 degrees. After that, air pressure automatically blows the magnetic packages out (into the closed drum). Once the magnets are far enough out, the captured ferrous particles fall from the tubes. Collect and discharge them.

Cleaning / iron discharging sequence:

- Stop the product flow.

- Loosen the locking clamps.

- Grasp the grip and pull the drum / magnetic rotor completely outside.

- Rotate the drum 90 degrees anti-clockwise and secure it with the locking pin.

In this extreme position the magnets in the tubes slide automatically to the outside so that the captured metal particles automatically drop off the tubes. Collect and discard the falling metal parts. - Rotate the drum back into position and push the rotor back against the hydroformed housing.

- Fasten the locking clamps.

- Restart the product flow.