Mobile MetalXpert - Eddy current separators

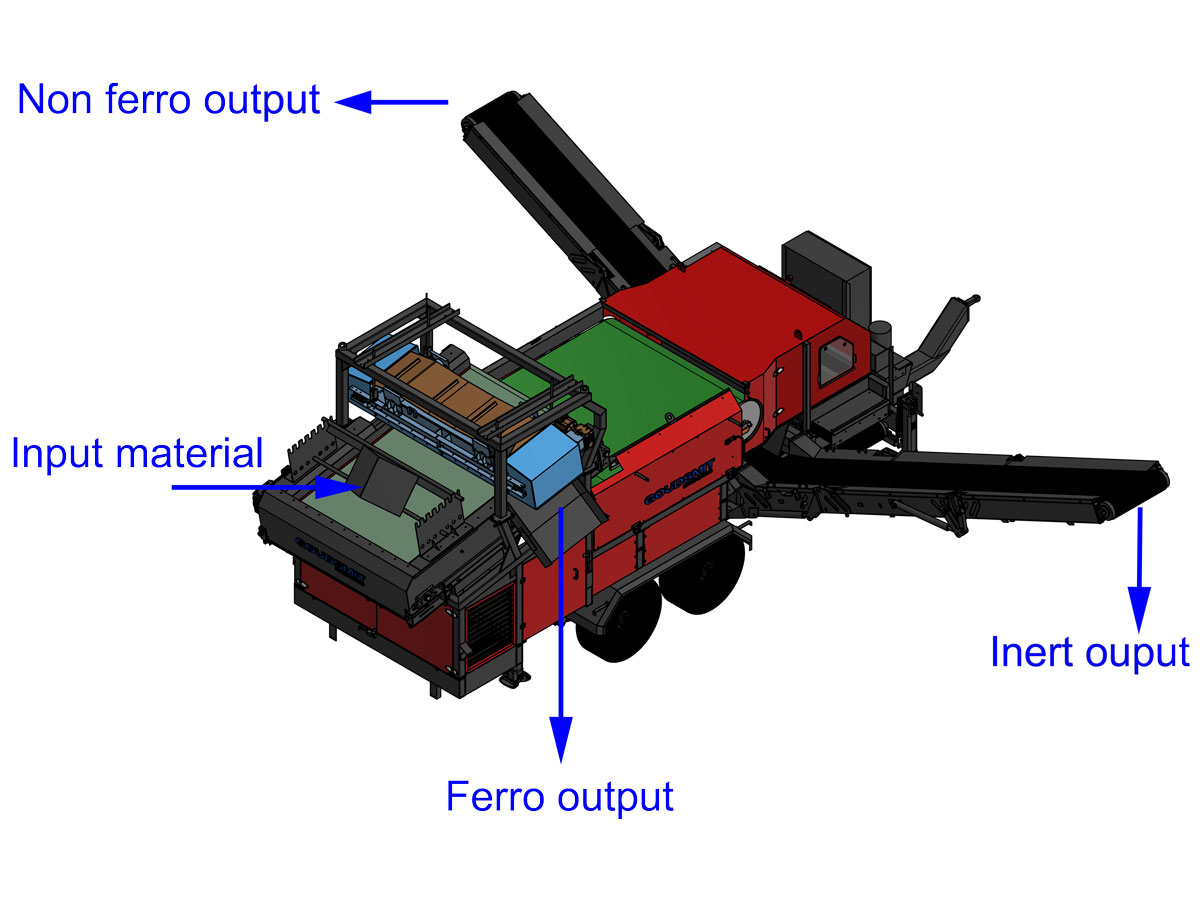

A mobile magnetic separator is designed to be installed at a building site or in the field. It separates both ferrous and non-ferrous metals in one step from large bulk flows. This leaves you with three separate material flows: ferrous, non-ferrous and clean (inert) bulk material which is suitable for reuse.

- 12 or 22HI -pole eddy current magnet roller

- Combined ferrous and non ferrous separation

- Separating NF particles 5-200+ mm

- Quick and efficient

- Easy to install

Application

Mobile eddy current separators are often placed behind mobile shredders or sieves as the final purification step. But we also use them stand-alone to recover metals from large piles of material on site. They process high capacities because the conveyor belt separates and disposes of non-ferrous metals continuously and fully automatically. You can place them anywhere at a building site or in the field. The mobile separator is built on a tandem trailer and is certified for towing on public roads.

The built-in generator unit makes it possible to operate in places where there is no power supply. Of course, you can also connect the machine directly to the mains.

Applications of the mobile eddy current separators include for instance the recovery or purification of ferrous and non-ferrous metals from:

- shredded wood

- construction and demolition debris

- refuse derived fuel

- industrial waste

Design

The separators are very compactly built. This makes certification for towing on public roads possible.

There are many options available to tailor the mobile separators to your needs, such as:

- diesel power generator

- 12- or 22HI-pole eddy current rotor

- ferrite or neodymium overbelt

Operation

For a good magnetic separation of ferrous and non-ferrous metals, an even supply of material is important. The ideal situation is a mono-layer. Here the supplied layer thickness is about as thick as the largest piece, and thus that there are no pieces lying one on top of the other. This ensures optimum magnet performance.

The mobile Goudsmit separator has a distribution plate at the material inlet point. This plate ensures an even spread so that the material lies in the breadth across the slanted feeder belt.

As a first step, the overband magnet extracts all the iron parts from the flow and disposes of the ferrous parts to the left or to the right as required. After the iron parts are removed, the bulk is transported to a two-metre-wide eddy current separator. There, a powerful 12- or 22HI-pole rotor separates the non-ferrous metals from the bulk material.

The metal separator has a working width of 2,000 mm. This results in the case of shredded wood in a capacity of approximately 100 m³/hour.