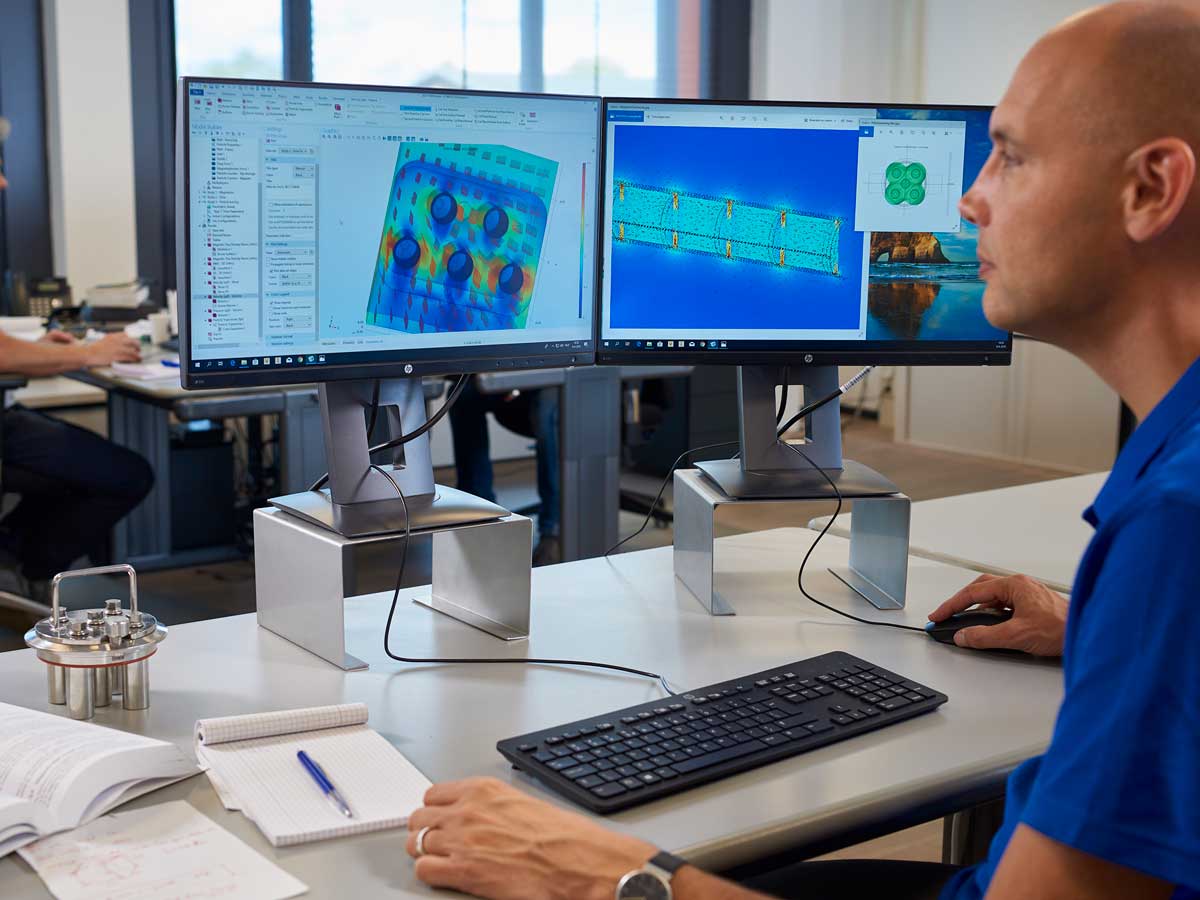

Goudsmit: driven by magnetism

Мы разрабатываем, проектируем и изготавливаем высокотехнологичные магнитные компоненты и промышленные магнитные системы.

Мы поставляем эти системы предприятиям пищевой, автомобильной, перерабатывающей, металлургической, фармацевтической, химической, аэрокосмической промышленности и шельфовой нефтегазодобычи, а также наукоемким отраслям, во всем мире.

- Разработка, производство и обслуживание

- Индивидуальный подход

- Соответствие международным стандартам безопасности материалов

- Сертификаты ISO9001 и ISO14001

- Сертификаты IATF1694

Нужна дополнительная информация?

Для получения дополнительной информации обращайтесь по телефону: +420 318 599 550

или по электронной почте: info@wamag.cz.

Вы можете найти нужный контакт Goudsmit на нашей странице контактов.

Linkedin – Facebook – Youtube