Goudsmit: Die Kraft des Magnetismus

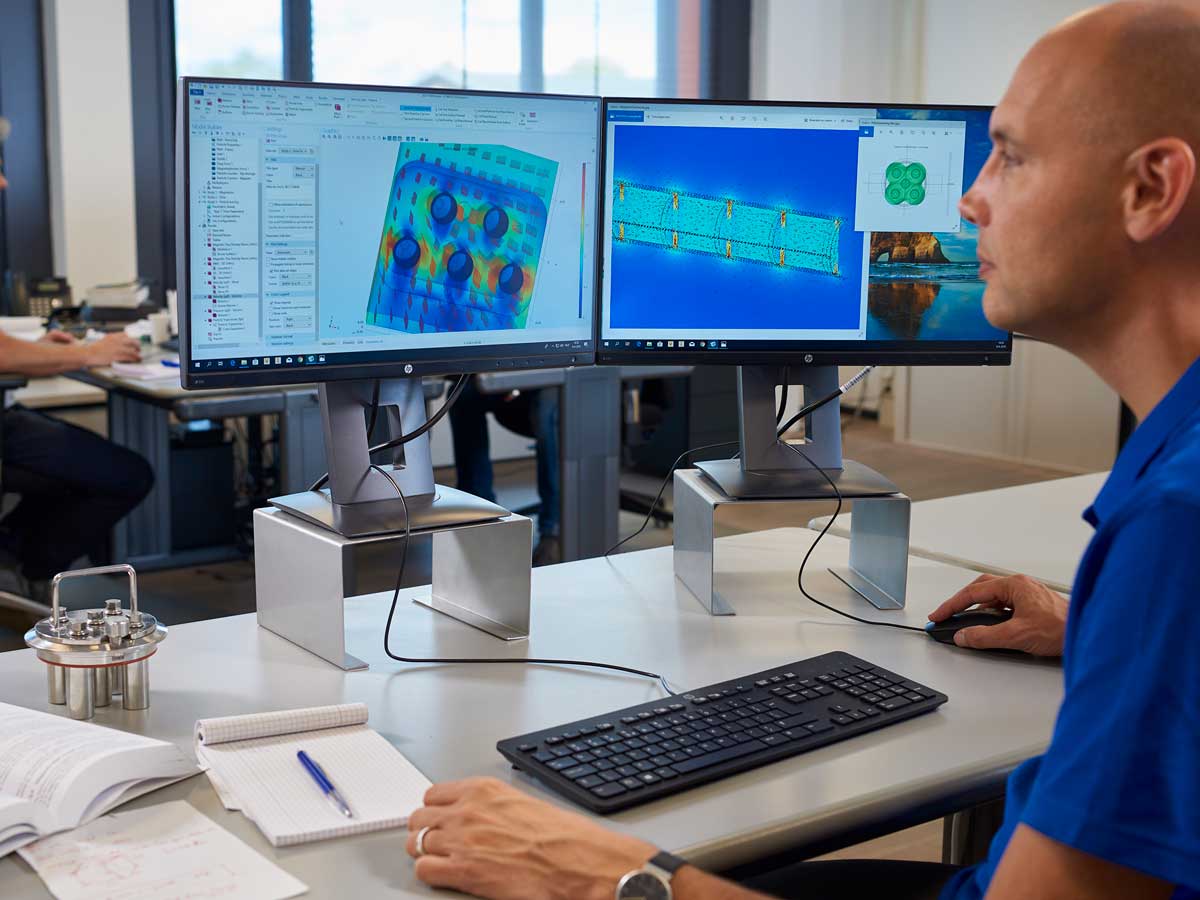

Seit über einem halben Jahrhundert entwickeln und bauen wir High-Tech-Magnetkomponenten sowie industrielle Magnetsysteme.

Wir liefern diese Systeme weltweit an die Lebensmittel-, Automobil-, Recycling-, Metall-, Pharma-, Offshore-, Chemie-, Hochtechnologie- und Luftfahrtindustrie.

- Engineering, Produktion & Service

- Auf Ihre Wünsche abgestimmt

- Einhaltung internationaler Standards für Materialsicherheit

- ISO9001 und ISO14001 zertifiziert

- Nach IATF16949 zertifiziert

Weitere Informationen?

Für weitere Informationen rufen Sie uns an: +31 40 2213283

oder schreiben Sie eine E-Mail an: info@goudsmit-deutschland.de

Die richtige Kontaktperson bei Goudsmit finden Sie auf unserer Kontaktfinderseite.

LinkedIn – Facebook – YouTube