Metal contamination

The assessment of the incoming material makes it clear whether you as a supplier have delivered on what was agreed.

The timely removal of unwanted metals prevents metal contamination of products.

The consequences of this contamination are often difficult to predict. Think of end-user damage claims. Or costly product recalls that damage your reputation.

But also disruptions, wear or damage to the machinery that cause stoppages of entire production operations as well as delays.

Magnets separate metal from seeds and grains

Solution

Goudsmit offers a customized magnet solution for each product and associated transportation. Whether it be the loading or unloading of ships, tanker trucks or silos.

Of course we take into account the product’s properties, the level of contamination, the speed of flow, discharge, cleanability and the accessibility of the systems.

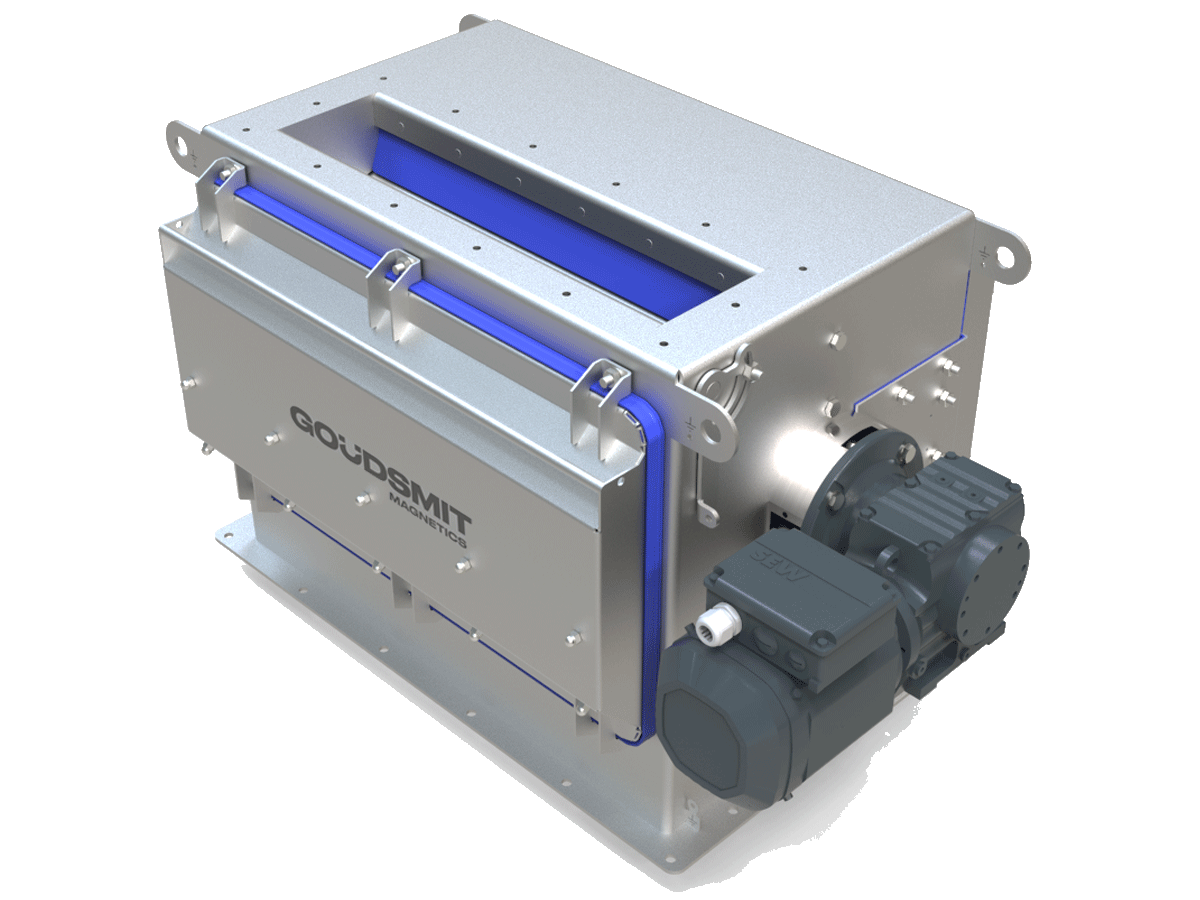

High-Gradient magnetic separator

We have designed a special magnet, namely a high-gradient magnet, for removing metal particles from seeds. It distinguishes the good, healthy seeds from unusable seeds. Its functionality is based on the use of a strong separation roller and works as follows:

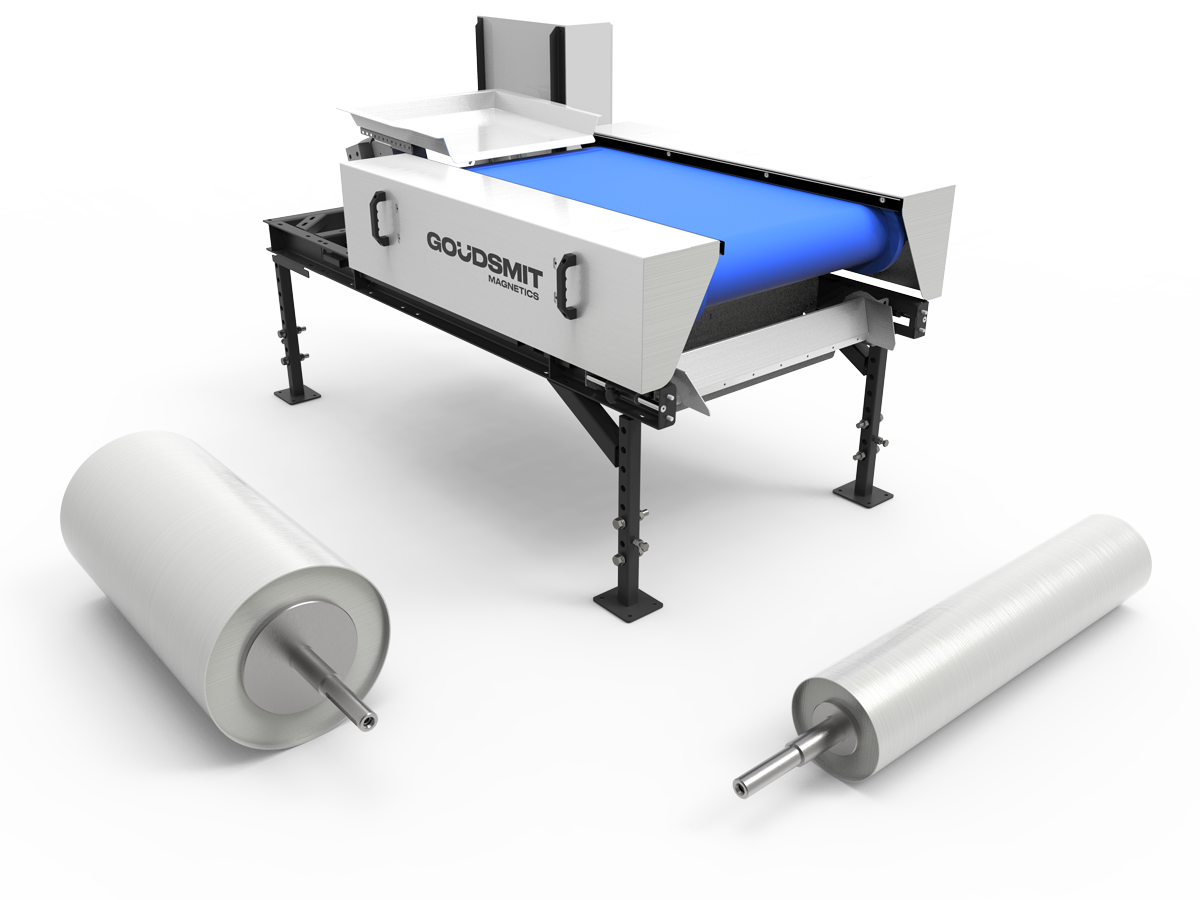

High-gradient magnetic head pulley separator

Separate good from bad seeds

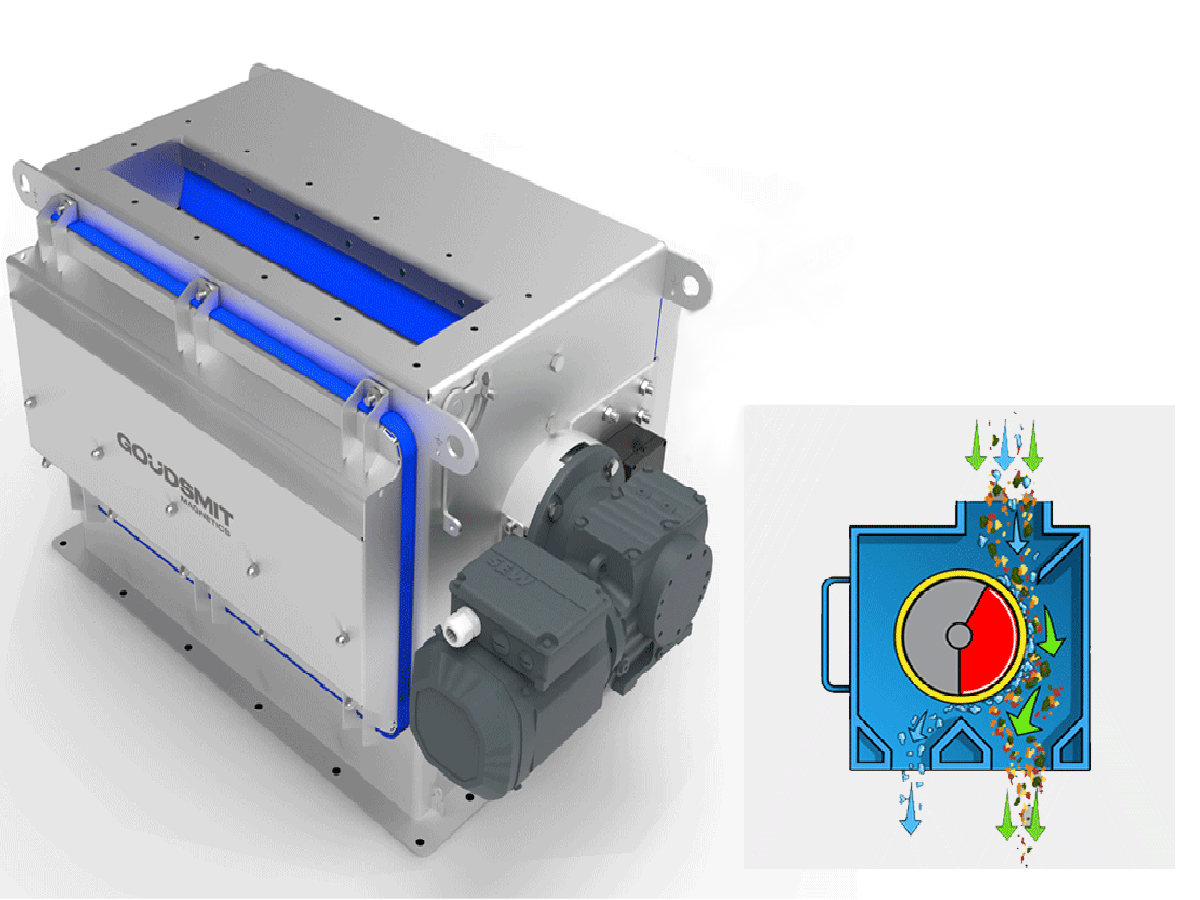

The (vegetable) seeds are first dipped in a bath of Fe powder and then washed and dried. Any open seeds pick up iron particles, and become magnetized. The particles that are in good condition and still shut, remain metal-free. this process requires a very strong magnet of 10.000 gauss.

Increase your product quality

The high-gradient separator is such a strong magnet. It enables you to quickly and easily improve the quality of your bulk flow finished product.

High gradient separators are only suited for low capacities. For higher capacities in free fall processes we advise you to use magnetic drum separators.

They are excellently suited for bulk flows like maize, grain, malt, barley, sugar, cocoa beans, sunflower seeds, rape seed, tapioca or soya.

Drum magnet separator for food applications - working