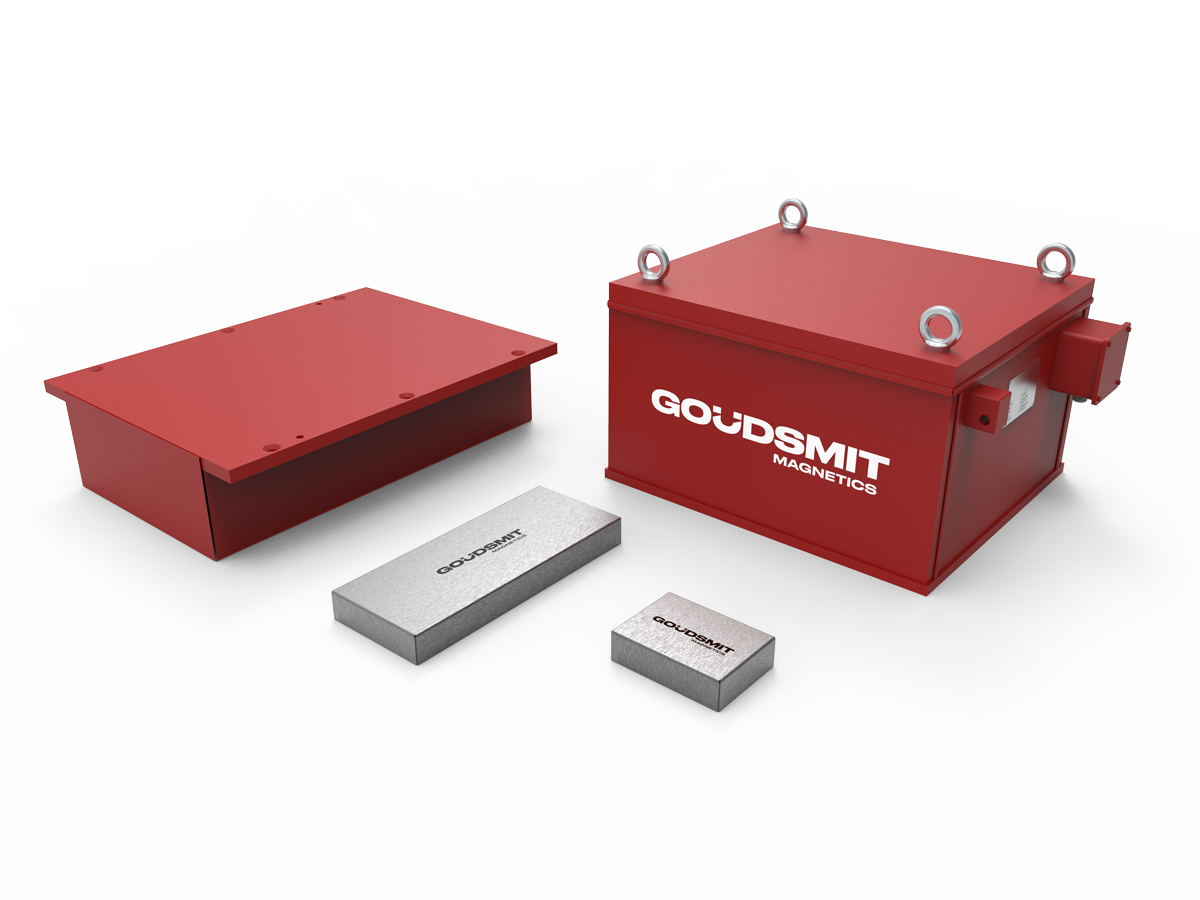

Suspension magnets

Installation above conveyor belt in bulk loading or recycling industry. Extract metal parts from raw material flows with little ferrous contamination....

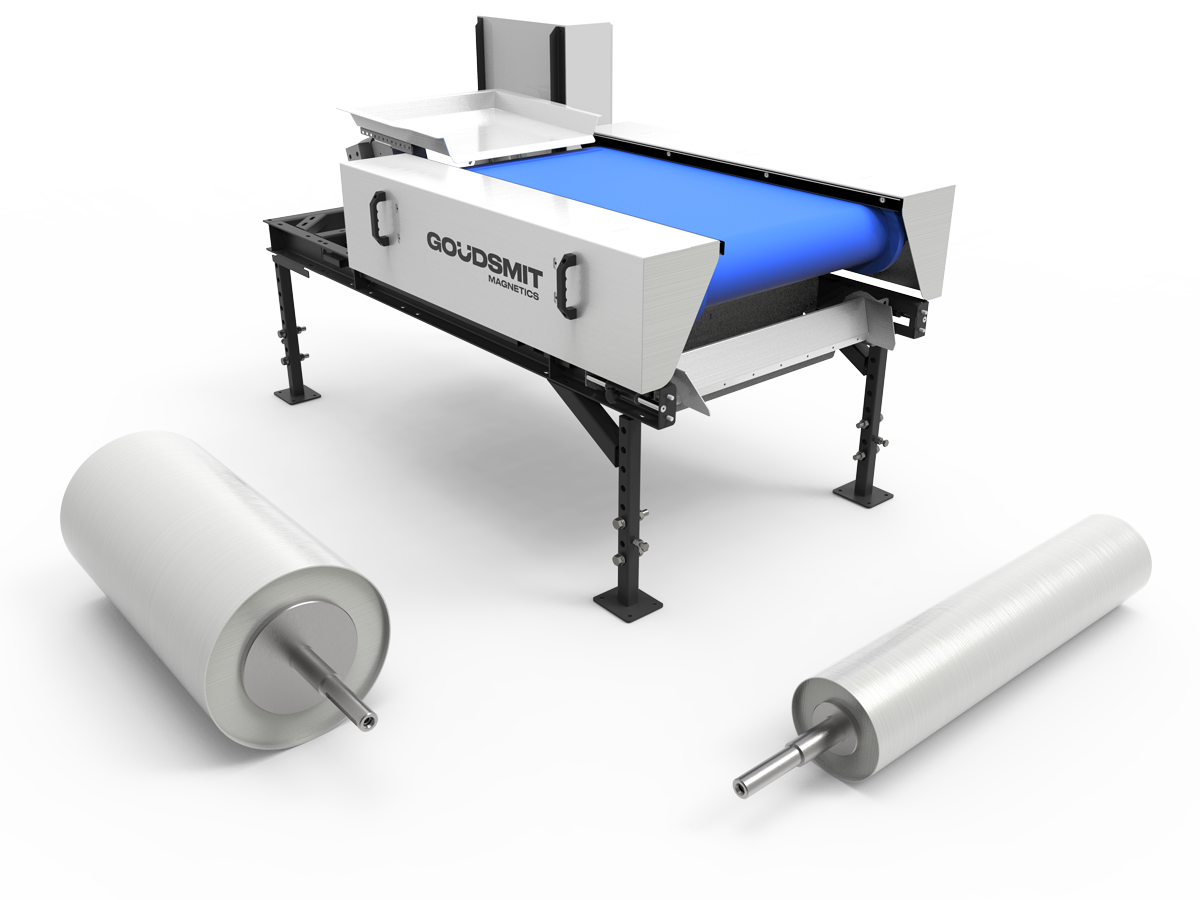

Magnetic head pulleys

Installation in an existing conveyor belt system in bulk loading or recycling industry. Filtering of difficult shapes of ferrous and weakly magnetic p...

Magnetic drum separators

Installation in an existing process or as an independent system. Automatic and continuous filtering of large amounts of ferrous and weakly magnetic pa...

Overband magnets

Installation above conveyor belt in bulk loading or recycling industry. Automatic removal and disposal of large amounts of ferrous contamination.

Eddy current separators

Filtering, separation and recovery of non-ferrous metal parts such as copper and aluminium. Adjustable magnetic field, robust construction.

Tools

Magnetic tools help you with simple operations. In this way, you can measure, clean up, pick up or fasten things yourself.

Magnets for recycling & sorting

Magnetic separators separate and sort metal parts from waste flows. This often concerns valuable metals, which means that the payback time of separators for recycling is short.

In this way, waste products are made reusable for new applications. Examples include Green Deal, Urban Mining, E-Waste recycling or the EU Waste Directive 2008/98/EC; the trends for the future.

Magnetic separators are intended for:

Separation/recovery of ferrous metals, such as iron, steel and weakly magnetic metals such as machined stainless steel

Overband and suspension magnets are distinctive in terms of service life, robust construction, magnetic force and magnetic field depth.

For product flows with sharp metal parts, where a conveyor belt is a poor choice, we recommend (scrap) drum separators. These are extra robust, which makes them almost maintenance-free and durable. When there is little space available for installation, magnetic head pulleys are the best solution for removing ferrous metals from a bulk or other product flow.

Separation/recovery of non-ferrous metals, such as aluminium, copper, zinc, gold, silver and magnesium

Eddy current separators separate and sort non-ferrous metals such as aluminium and copper from primary or secondary raw material flows. We often use a combination of these separators one after the other. For the best separation efficiency, the fraction has a certain bandwidth in terms of particle size.

There is an optimal magnet system for every fraction distribution. By strategically placing these in the process line, you can optimally recover valuable metals. Goudsmit’s specialists are happy to advise you on the most effective placement of these machines.

Purifying product flows

With magnetic separators you can purify or clean up unwanted ferrous or non-ferrous parts from (bulk) product flows. For example, shredded plastic bottles/flasks, which contain (stainless) steel balls and springs in the spring mechanism. For a clean, reusable plastic flow, you want to remove these unwanted parts.

More info?

View all applications on the Recycling industry page.