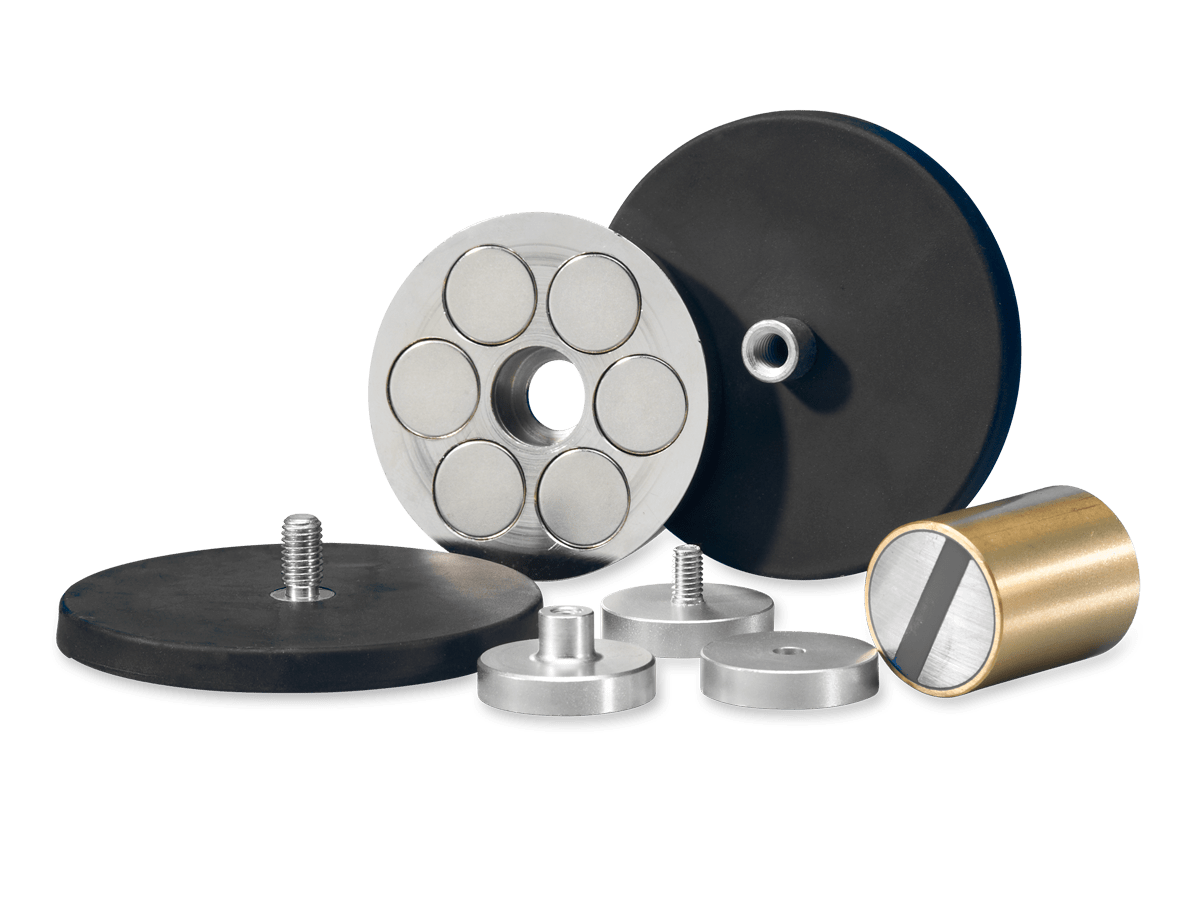

Flat pot magnets

Compact flat magnet systems available in neodymium, samarium cobalt and ferrite. Suitable for gluing. Thanks to the shell of these magnet systems, the magnetic field strength increases and the pot magnets are more resistant to corrosion or chemicals. Pot magnets have a single attracting surface. This precludes dispersion of the magnetic field.

The specified holding forces are measured under optimum conditions: perpendicular, on a piece of grade 37 steel that has been ground flat with a thickness of 5 mm, without an air gap.

- Deliverable from stock

- Available in various sizes

- Available with extra strong magnet

- Buy magnets online

What does a neodymium pot magnet consist of?

These super-strong pot magnets are made of the alloy neodymium-iron-boron - (NdFeB) - which Goudsmit markets under the brand name Neoflux®. The shell provides magnetic shielding. Goudsmit supplies neodymium pot magnets with a brass or steel shell. The holding surface is covered with a protective coating to prevent corrosion.

When does loss of magnetic strength occur?

Neodymium cylindrical, flat pot magnets have a maximum operating temperature of up to 80 °C. When heated to this temperature, the magnet loses 15 to 20% of its magnetic force. This is not permanent; the force is restored when the magnet returns to the normal ambient temperature.

External magnetic fields may also cause loss of magnetic force. An air gap or non-magnetic materials located between the magnet and workpiece reduce the tensile force.

Magnetic short circuit

To prevent loss of holding force due to magnetic short-circuit, neodymium magnets with a brass shell may not be pressed directly into steel. Always maintain a minimum distance between the brass shell of the pot magnet and the steel. Contact Goudsmit for specific recommendations.

E-mail or call +31 (0)40 221 3283.

Good magnetic properties, affordably priced

Ferrite pot magnets, also referred to as ceramic pot magnets, are fitted with a steel pot that provides shielding of the magnetic field. Flat ferrite pot magnets require only a minimal installation height. This provides constructive advantages.

Ferrite pot magnets are corrosion-resistant and therefore do not require additional coating on the magnet surface.

When does loss of magnetic strength occur?

Ferrite pot magnets have an operating temperature of up to 200 °C. When heated to this temperature the magnet loses 30 to 40% of its magnetic force. This is not permanent; the force is restored when the magnet returns to the normal ambient temperature.

External magnetic fields may also cause loss of magnetic force. An air gap or non-magnetic materials located between the magnet and workpiece reduce the tensile force.

Corrosion-resistant

Ferrite pot magnets do not corrode and are suitable for outdoor use.

Second strongest type of magnet

Samarium-cobalt pot magnets offer the unique combination of high magnetic force and high operating temperature. These super-strong pot magnets are made of an alloy of samarium and cobalt. The holding force at room temperature is 5 times higher than that of ferrite pot magnets.

With the exception of Neoflux® pot magnets, samarium cobalt pot magnets are the strongest that we have in our product range.

When does loss of magnetic strength occur?

Samarium cobalt pot magnets have an operating temperature of up to 200 °C. When heated to this temperature, the magnet loses 15 to 20% of its magnetic strength. This is not permanent; the force is restored when the magnet returns to the normal ambient temperature.

External magnetic fields may also cause loss of magnetic force. An air gap or non-magnetic materials located between the magnet and workpiece reduce the tensile force.

Installation and demagnetization

Samarium cobalt pot magnets are very stable and are difficult to demagnetize in a strong alternating current field.

The steel pot does not provide any magnetic shielding. Therefore, these pot magnets may not be built into steel components without taking special measures. The distance between the steel component and the samarium cobalt pot magnet must be 1.5 to 6 mm, depending on the size of the pot magnet.