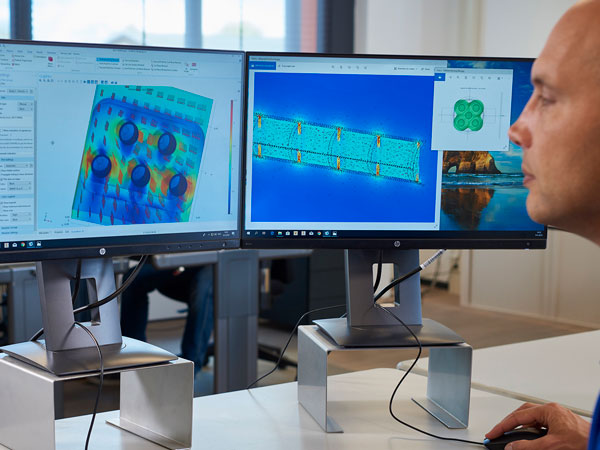

FEM simulations & magnet calculations

With FEM simulations & magnet calculations we can design the best magnet system for you. We combine your concept with our magnet knowledge and thus accelerate your innovation and development process. This saves you valuable time and unnecessary costs.

FEM simulation

Do you want certainty about the operation of a magnet system?

By means of FEM (Finite Elements Method) simulations, our engineers design magnet assemblies, both in 2D and in 3D. The early application of simulations and calculations prevents design errors, makes your product cheaper and gives you direct insight into the operation of your prototype or end product.

The advantages of FEM simulations for you:

- accelerates your time-to-market;

- prevents design errors;

- quick insight into the operation of a prototype, magnet or assembly;

- an optimized, cost-effective product;

- reduced risk of production errors;

- saves time and money.

Optimizing magnetic performance with FEM

Magnet material such as neodymium is precious. This makes it extra important to use this material optimally. FEM simulations plus our experience and knowledge of magnetism allow us to accurately predict how the magnet will behave in terms of:

- depth of the magnetic field;

- effect on a nearby sensor and the associated switching action;

- peaks and troughs in the magnetic field over a surface;

- maximum force of the magnet on another ferromagnetic object;

- 'residual magnetism' present when switched on and off for switchable magnets;

- separation of particles from a product flow of powder or liquid, for example.

Want to learn more? View our Whitepapers.

Magnet quality determination

Are you looking for the right grade or magnet quality for your application?

Goudsmit can help you calculate the right magnet quality for your application. Magnets can lose their magnetic attractive force over time. This has a variety of causes, such as temperature fluctuations or opposing magnetic fields that exert pressure. To prevent your magnet assemblies from losing their strength or becoming undesirably demagnetized, our experts carry out magnet quality determinations.

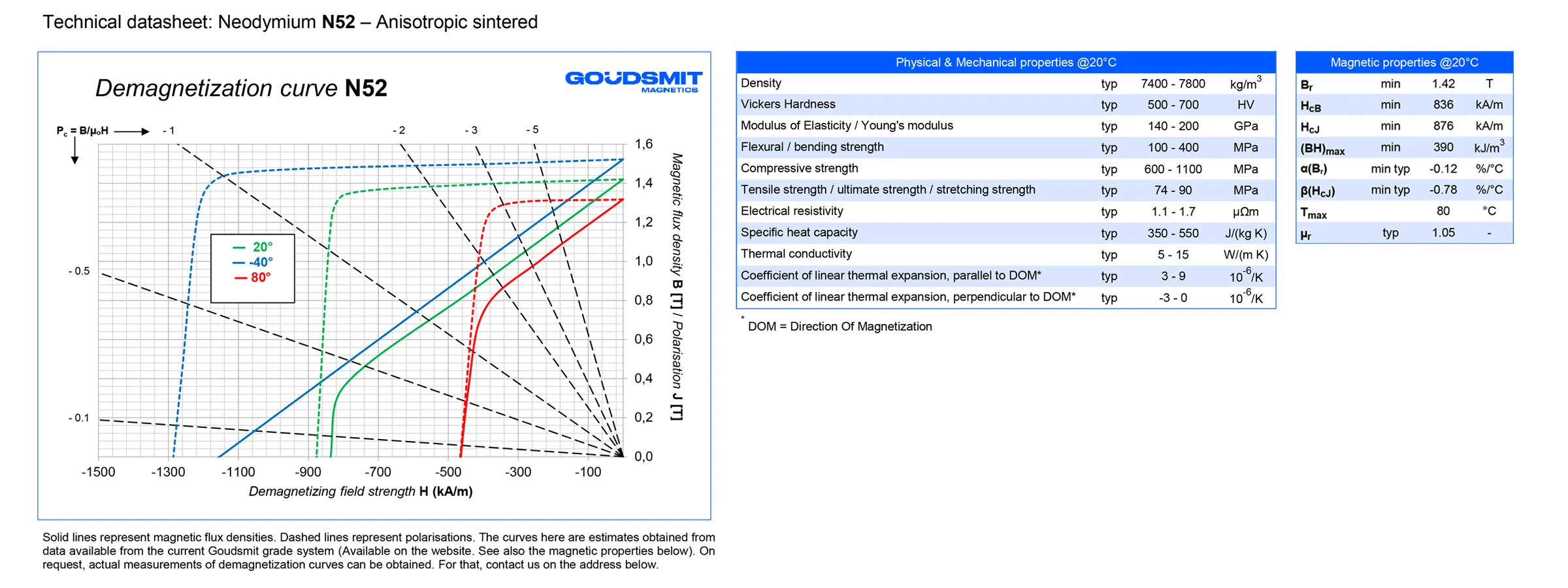

Quality rating from N35 to N52UH and beyond

The different magnetic materials each have their own quality rating. Our experts help you determine the quality of your magnetic material. This is expressed in quality names that indicate the height of the maximum energy product. This is often in the unit MGOe (Mega Gauss Oersted). The maximum energy product is a measure of the strength of the magnet. For neodymium magnets this is reflected in Nxx ratings. The higher the N value, for example N52, the higher the maximum energy product and the stronger the magnet.

What determines the maximum energy product?

We determine the optimal quality of your magnet, and thus the maximum energy product, by calculating the effect of the selected magnet quality on your application. We compare the magnetic properties of the chosen magnet material, such as the demagnetization curve, in the calculation software. We also take temperature into account, as it can significantly change the magnet properties. For instance, neodymium is the strongest material at normal temperatures, but samarium cobalt is often the strongest magnet at higher temperatures.

Which magnetic materials are there?

We distinguish different types of magnet materials, each with its own rating (grade) and therefore Max. energy product:

Magnet material - Max. energy product

- Neodymium - 35–52 MGoe

- Samarium cobalt - 20–32 MGoe

- Ferrite - 1–5 MGoe

- Alnico - 5–9 MGoe

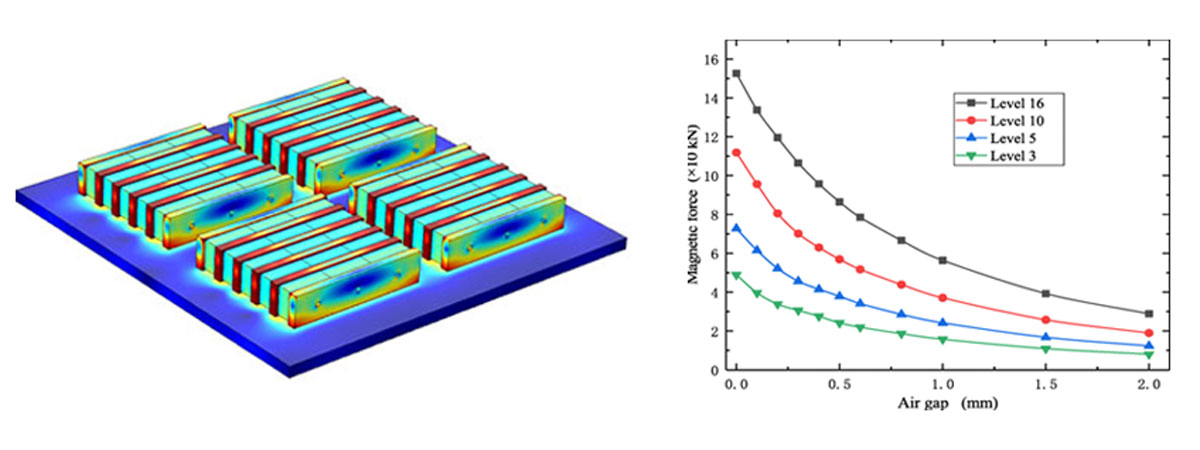

Magnetic holding force calculation

Do you want to know exactly what the magnetic holding force is of your magnet or assembly?

Our engineers can help you determine the exact holding force. This avoids surprises when testing prototypes.

What is magnetic holding force?

Magnetic holding force is the force required to detach a magnet from another magnet or steel plate. Another definition is: the maximum weight that can be hung perpendicular to a magnet, converted from kilograms to Newtons. Several factors influence this force, for example:

- magnetic material

- volume of the object – for example, the thickness of a steel plate

- temperature

- the coating with which the magnet is finished.

Why do we calculate holding force?

Our experts use complex calculations and simulations of your product design to determine exactly what the magnetic holding force is under different circumstances. This ensures the correct operation of your product. For different applications, motions and variables, the magnetic holding force may be lower than expected, resulting in your product not meeting specifications. The force can also be greater than the specified force, so that a less strong or smaller, therefore more cost-effective magnet may also be sufficient for your application. So don’t end up with any surprises and ask our experts to assist you with the choice of magnet with simulations.

It may also be that the holding force is not important to you, but the force between the magnet and another object at some distance, referred to as the 'air gap', is important. We can also calculate this force for you.

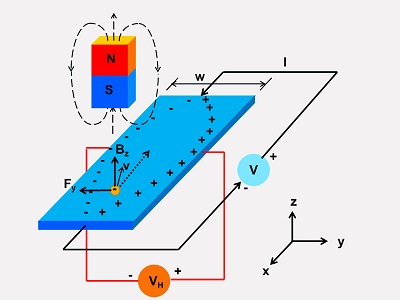

Magnetic field calculation

Do you want to know exactly what the magnetic field strength is for your product design?

Our engineers are happy to calculate this for you. They will also help to determine the best magnet for the required magnetic field strength. This ensures that you do not have to use unnecessary force to achieve your application target. It saves on costs when choosing the right magnet quality.

Calculating magnetic fields & flux density

Magnetic field strength is often expressed in terms of the magnitude of the magnetic flux density. The 'e' is a vector quantity with both a certain force and direction and with three components (in x, y, and z direction). We express the magnetic flux density in tesla or gauss. Tesla is the official unit but gauss was and still is widely used (Note: 1 tesla = 10,000 gauss).

Using industry-leading software, our experts can help you calculate magnetic field flux densities. This offers you certainty about the ultimate operation of your product.

Validate polarisation direction to ensure safety

We measure the polarisation direction of magnets to ensure that the North and South pole distribution meets the specified specifications. This way, we prevent switching too early or too late when using the magnet in combination with a sensor for example. Determining the polarisation direction is part of a series of magnet calculations that Goudsmit can perform for you.

Remanence determination

Do you want to know exactly what the remanence of your magnet is?

Remanence measure for magnetisation

The remanence is a measure of the magnetism left in the magnet when it is magnetized. Magnetization is done by applying a strong external magnetic field over the material to be magnetized. This field ensures that all internal areas with the same magnetization direction, also called Weiss areas, point in the same direction.

Only with such rectification of these areas, which has an amplifying effect, do we obtain a sufficiently strong magnet. If the external field disappears, as well as the rectification of the Weiss areas, we call this soft magnetic material. If the rectification remains, due to internal frictional forces of the material, then we call this a hard or permanent magnetic material. The remanence is a measure of the amount of magnetism that then remains in the material.

Coercivity determination

Do you want to know exactly what the coercivity of your magnet is?

The coercivity is a measure of the magnet’s resistance to demagnetization when an external magnetic field is present nearby. It is therefore the resistance of a material to reversal of the magnetization directions in the Weiss areas by such a field.

Our specialists can use the permagraph to determine exactly what the remanence (expressed in tesla) is for you.

Need advice?

Our experts are at your service!

Use the contact form to ask them to help you with simulations, calculations and tests in material selection and save valuable time during your development process.