Magnetic bars

Part of many magnetic separators. Filtering of small ferrous particles and even stainless steel contamination from powder or granulate.

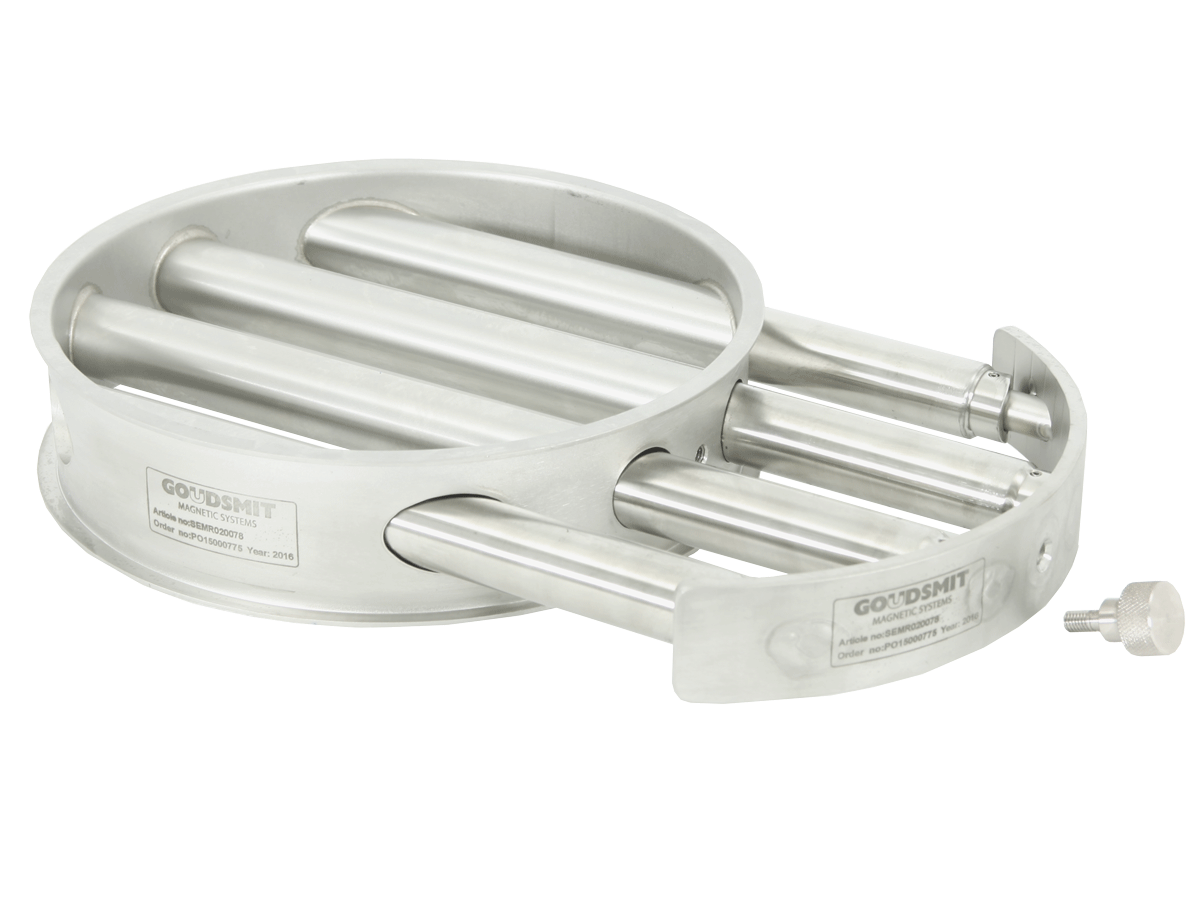

Magnetic grids

For good flowing powder and granulate. Often placed at a dumping point, as a control function. Manual quick-cleaning with extractor system.

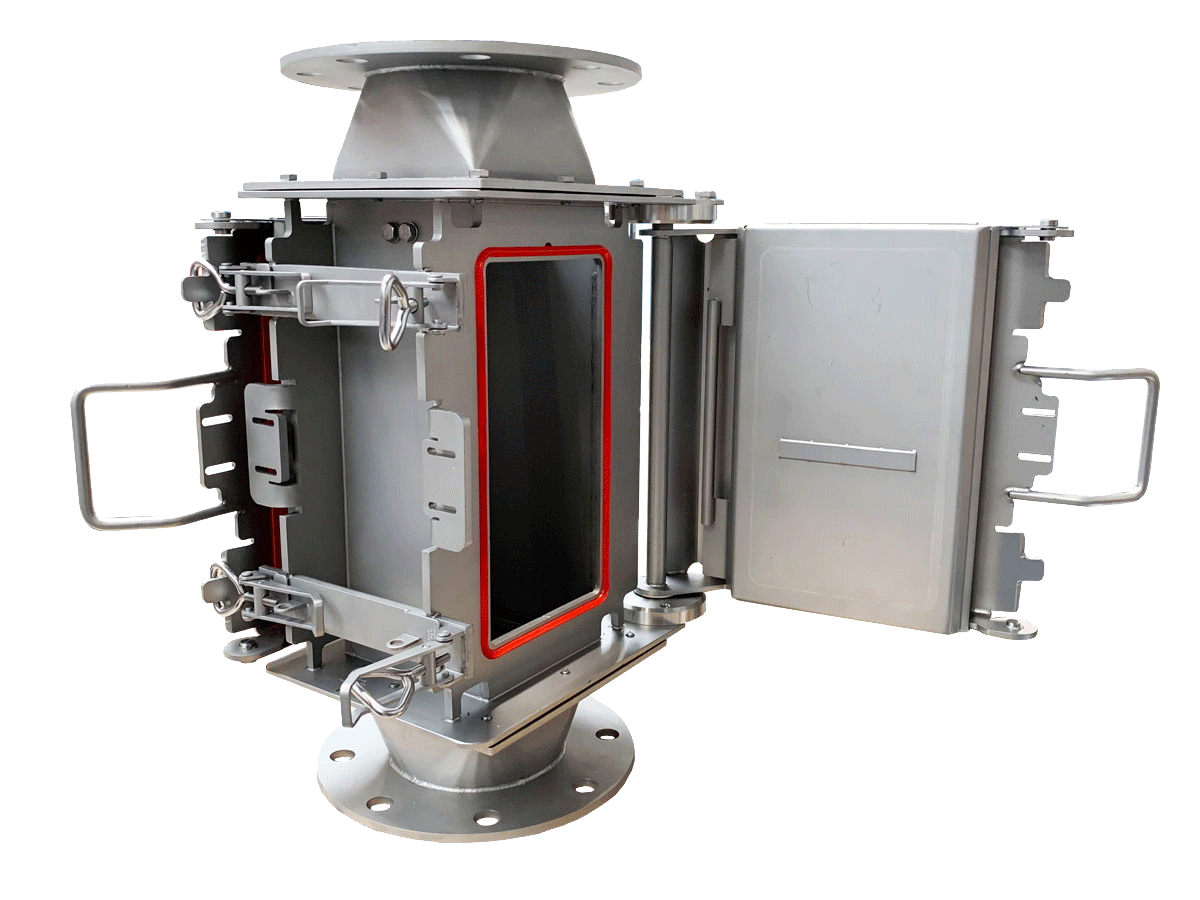

Cleanflow magnets

For powder and granulate, installation in free-fall pipes. Various types, from manual to continuous and automatic cleaning systems.

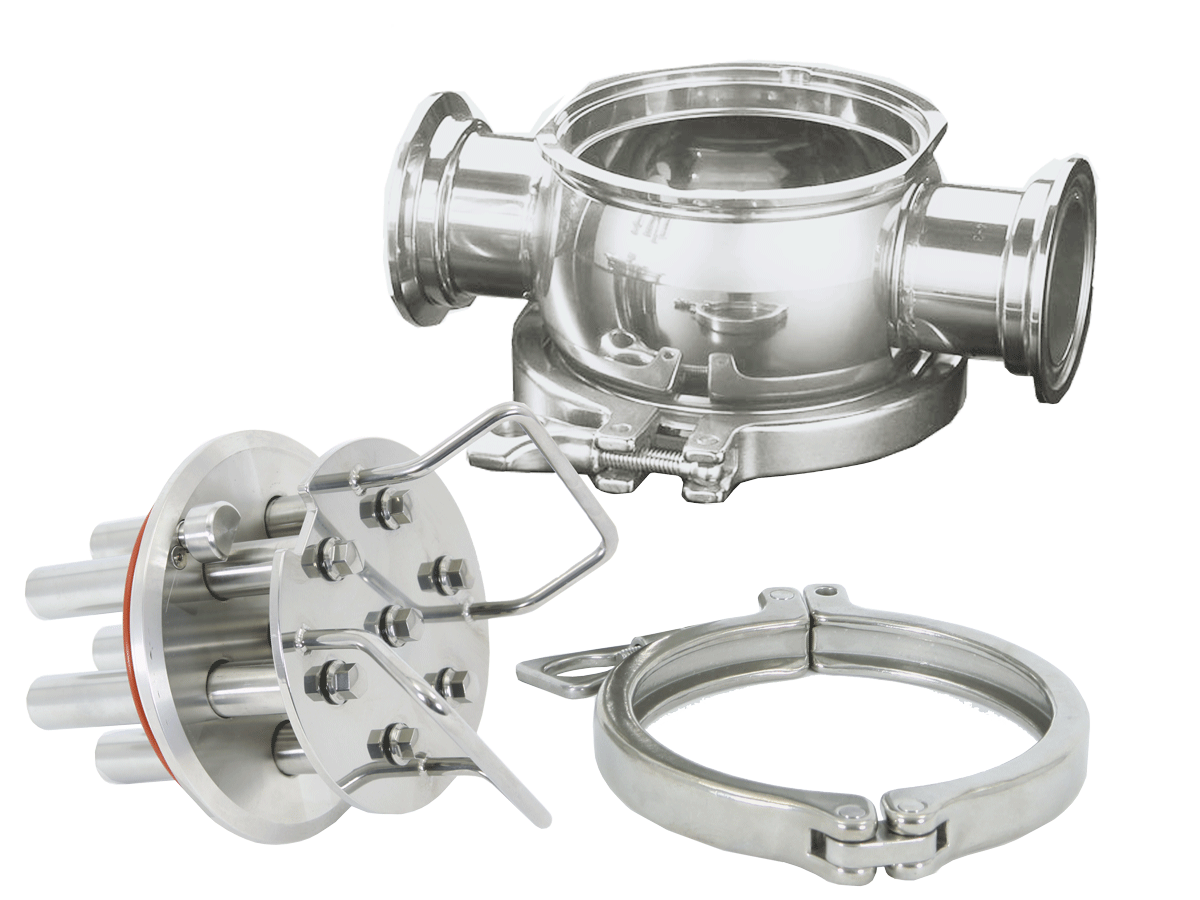

Magnetic filters for pressure lines

For liquid and powder in pipes under pressure up to 10 bar. From industrial to food/pharma, from manual to automatic CIP/SIP cleaning.

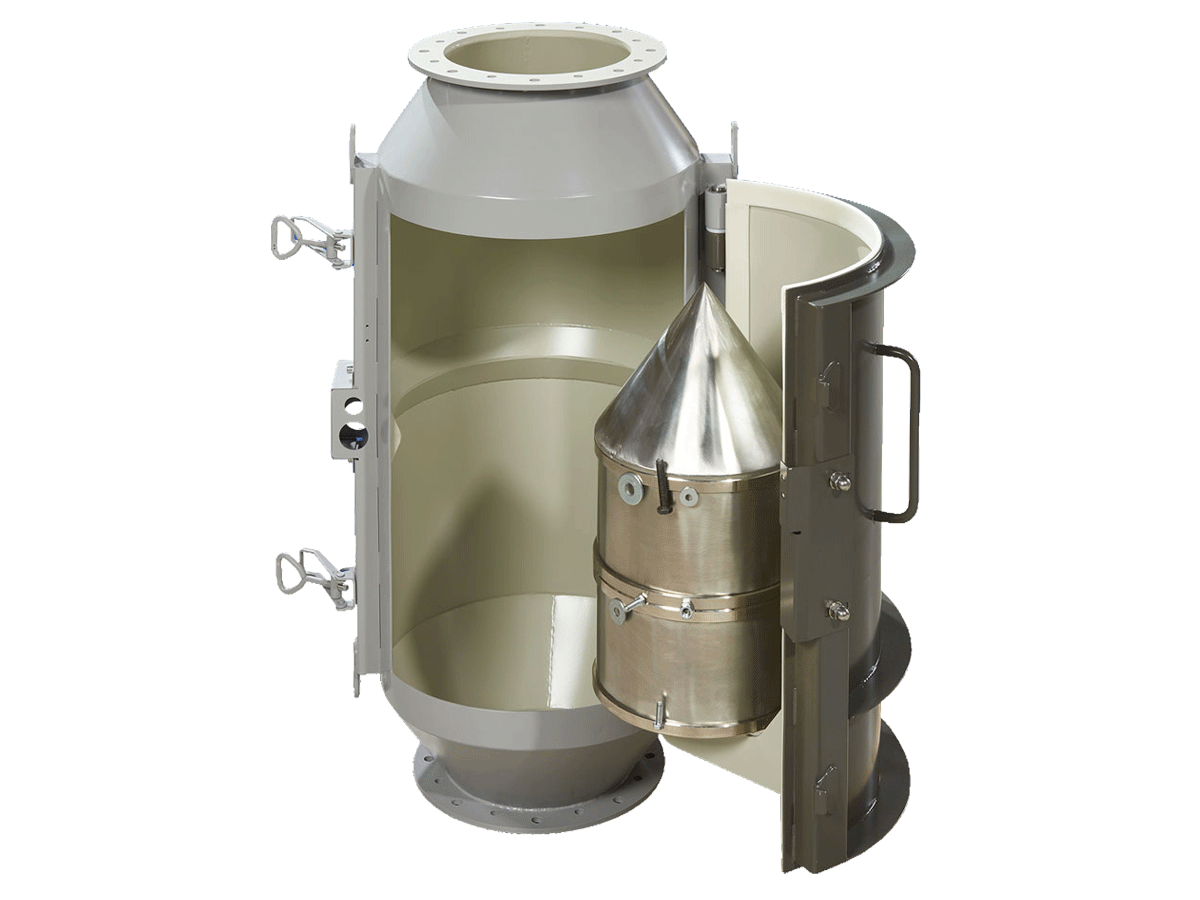

Bullet magnets

For coarse raw materials in free-fall processes. Good flow, high capacity. Manual cleaning (wipe-off) or automatic cleaning (electromagnet).

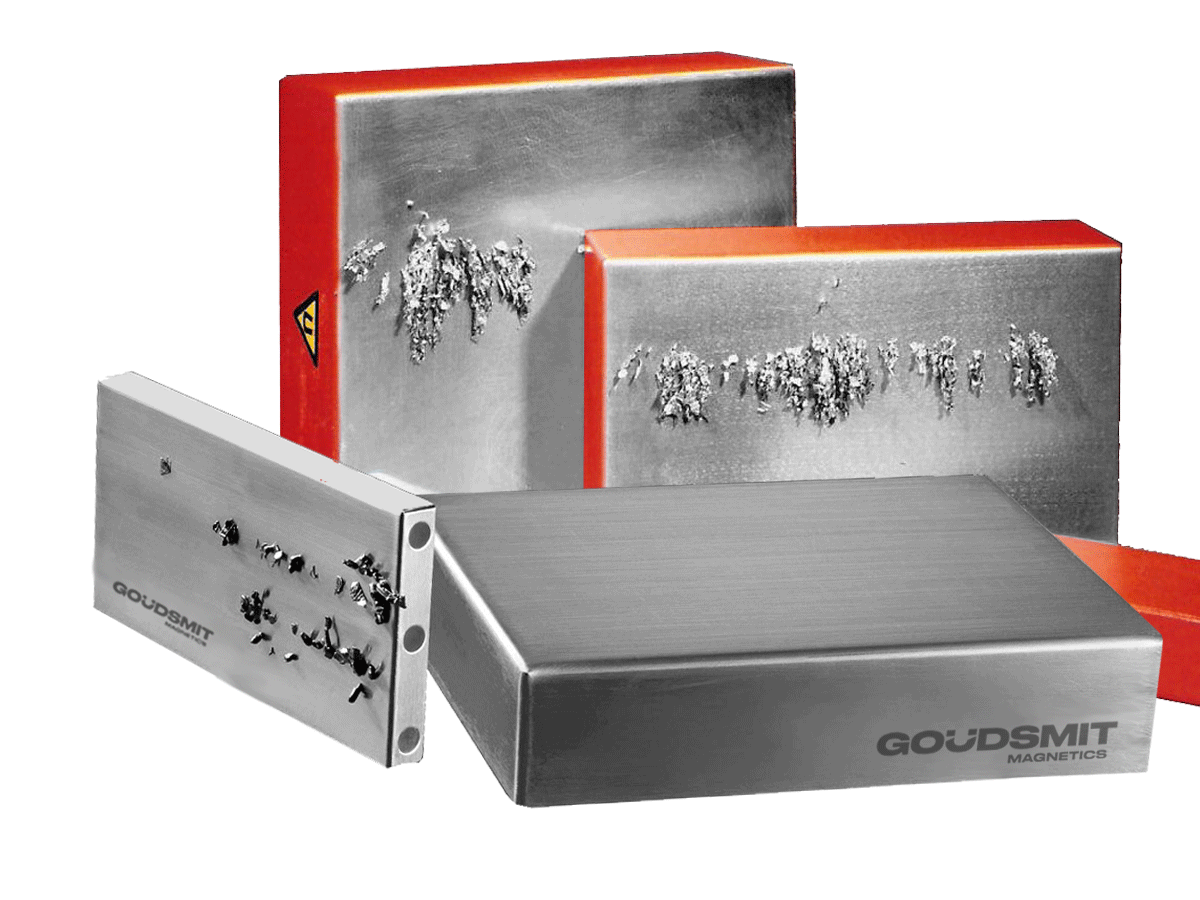

Plate & block magnets

Filtering of larger ferrous contaminants from coarse product flows. Component for magnetic separators in various designs. Manual cleaning.

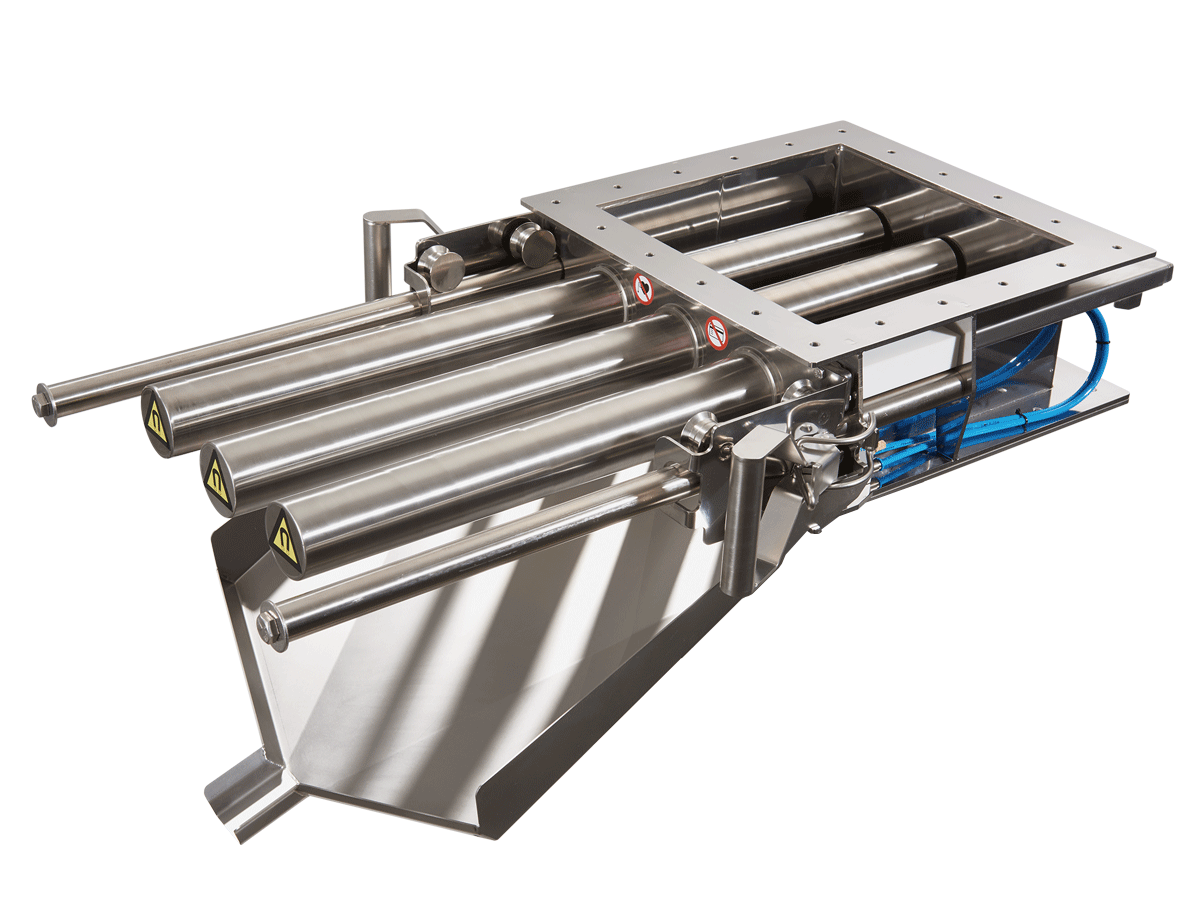

Chute magnets

For coarse powders and granules in free-fall processes. Very robust, free passage. Manual or automatic cleaning.

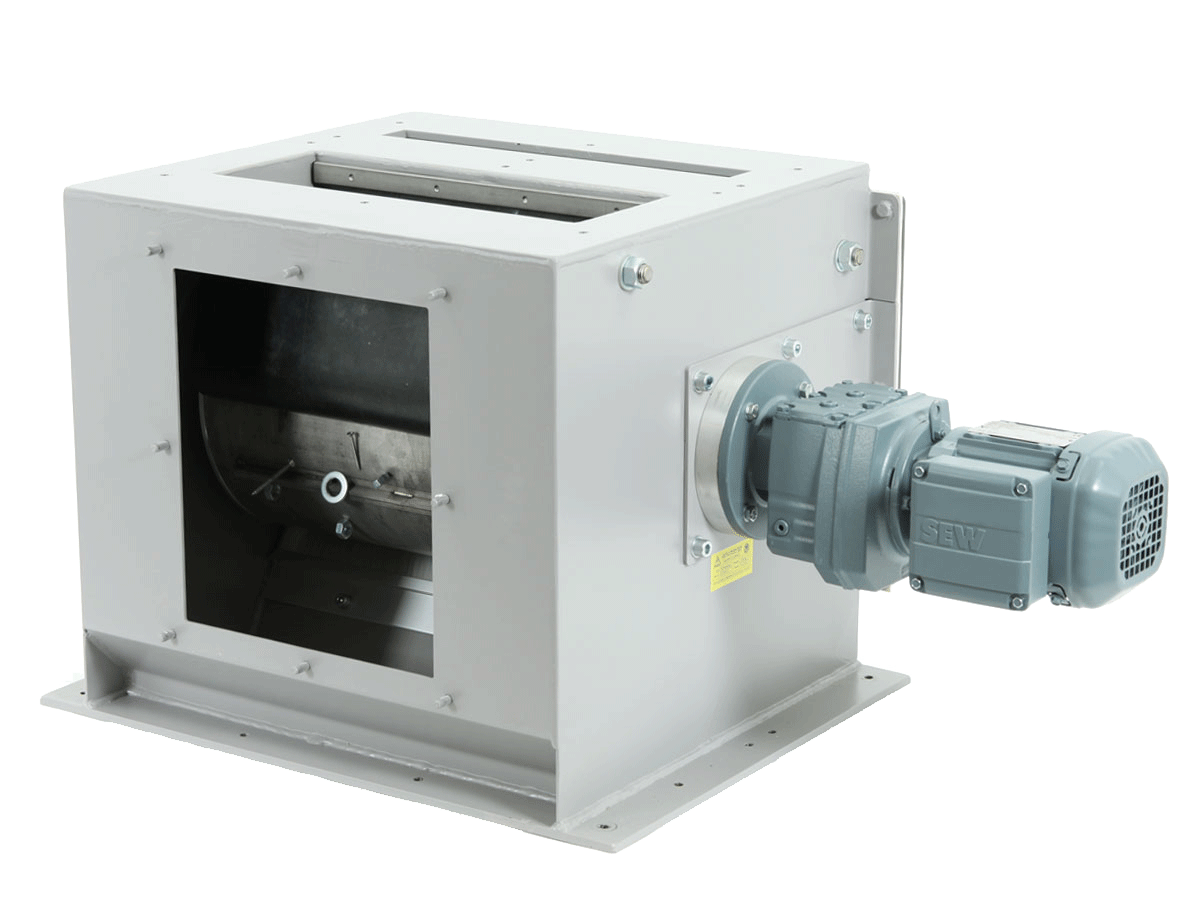

Drum separators

For product flows with a lot of iron particles in pressureless pipes. Aalso for weakly magnetic contamination. Continuous automatic cleaning.

Tools

Magnetic tools help you with simple operations. In this way, you can measure, clean up, pick up or fasten things yourself.

Application - removal of metal contaminants

Metal contaminants not only contaminate your product, they can also cause serious damage to your machines.

Magnetic separators filter large loosened parts to very fine worn particles. These can be removed in various ways: from manual wiping to fully automatic cleaning systems.

For every type of product transport

Magnetic filters and separators are suitable for any type of product transport:

- free-fall pipes

- pressurised pipes

- conveyor belts

Throughout the production chain

You can deploy magnetic separators anywhere in the production chain, from raw material intake to finished product processing. For example, placement in or near:

- conveyor belts

- dosing units

- fans

- filter units

- inlet and outlet of silos

- cyclones

- blenders

- inlet and outlet of sieves

- rotating valves

- sifters

- vibration units & shaking sieves

In every type of product flow

Magnetic separators are suitable for almost all conceivable types of product flows:

- Granular product flows, such as plastics, minerals and food products.

Examples: chamotte, quartz sand, glass, silica, corundum, plastic injection moulding pellets, cocoa beans, grains, sugar.

Magnetic separators: Cleanflow magnets | Chute magnets | Pipe magnets | Drum separators - Powdered product flows, such as food products, ceramics, minerals, pharma and chemical products.

Examples: cocoa, milk powder, flour, starch, tobacco, tea, coffee, spices, salt, lactose, baby food, talcum powder, lithium, aluminium oxide, titanium oxide, carbon black, animal feed, zinc oxide, calcium carbonate, medicine powders.

Magnetic separators: Cleanflow magnets | Chute magnets - Viscous product flows, such as fat and pasta.

Examples: butter, oil, melted chocolate.

Magnetic separators: Double-walled filter magnets - Liquids - flowing under pressure

Magnetic separators: Filter magnets

Three good reasons to install a magnetic separator

1. Magnets improve your product quality/purity

Not just in food products; even the smallest contaminants are undesirable in the pharmaceutical, chemical or ceramic industries as they lower the quality of the end product.

Rejected batches are costly, but it’s even worse if the contaminants are not detected and removed. You then run the risk of having to recall products. The consequence: huge costs and reputational damage.

2. Magnets prevent damage to your production machinery

You prevent damage and production downtime by installing a magnetic separator in bulk flows, in front of the inlet of your production machines. In machines such as grinders, ball and pin mills, calenders and crushers.

3. Magnets prevent dust explosions

Fine dust in combination with oxygen and a source of ignition can result in dust explosions. Filtering metal particles from the process prevents metal on metal from acting as an ignition source. You avoid serious injuries and damage to your machines.

Many of our magnetic separators are suitable for use in ATEX zone 20/21.

Goudsmit is a certified manufacturer of ATEX equipment. The quality assurance system is externally certified and guarantees the explosion protection of our magnetic separators.

Magnetic separator or a metal detector?

A magnetic separator removes the metal contaminants from the product flow. Magnetic separators have virtually no product loss and are suitable for removing large amounts of metal contaminants. Iron parts are removed during planned production stops or continuously during production. They cause hardly any product loss.

A metal detector only detects metal contamination. To remove the detected metal part, you must stop the production line or have an ejector remove the metal part. This leads to a lot of production and product loss.

More info?

Then visit our information page on magnetic separation.