Magnet inspections

Magnet inspections ensure the quality of the finished product. Inspecting and approving magnets is a prerequisite for proper operation in numerous products and processes.

Why magnet inspections?

The operation and performance of a magnet must be correct to ensure the quality of the end product.

Inspecting and validating magnets is a prerequisite for proper operation in numerous products and processes. Especially in the food industry, inspection of the magnet systems used is a requirement. Finished products must comply with the international food safety standard HACCP.

Our service engineers will also keep you up to date on the continuous technical improvements for the optimal separation of metal contaminants.

Contact our service department to make an appointment for a magnet inspection: call +31 (0)40 221 3283 or e-mail: service@goudsmitmagnets.com.

Read the whitepaper 'The value of fluxdensity measurement'

Or the newsitem about Magnet inspections and quality audits in the food industry

You can also watch the film: How to measure magnets.

Does a magnet become weaker over time?

In principle, no. Permanent magnets maintain their strength throughout their service life. However, there are a few reasons that may cause the magnetic force to decrease permanently:

- Heat: heat sensitivity varies according to magnet quality; some types of neodymium magnet begin to lose their strength at temperatures above 60°C. The magnetic strength drops to zero once the Curie temperature has been reached. The maximum temperature at which the magnetic strength is guaranteed is always listed in the product specifications of our magnetic systems. Ferrite is the only material that also weakens at low temperatures (below 40°C).

- Impact: impact load can alter the structure and direction of the magnetic "spins".

- Contact with external magnetic fields.

- Corrosion: corrosion may occur if the (coating of the) magnet is damaged or if the magnet is directly exposed to damp air. For this reason, the magnets are often built-in and/or protected.

When overloaded, electromagnets can overheat, possibly resulting in corrosion of the coils. This will also cause degradation of the magnetic force.

How do we conduct magnet inspections?

We check your magnets in the process line annually. In addition to measuring and inspecting the magnetic field strength, we also provide recommendations for process improvements. We record the measurements in an inspection certificate. For audits, this is a valuable report.

Inspections with minimal disruption of your processes.

With a calibrated gauss meter and minimal disruption of your processes, our service engineers carry out on-site measurements. They know exactly how and where to measure and check all installed magnet systems.

We also service other suppliers’ magnets.

For Goudsmit magnets, we then compare the measurements with the original values. If the magnet is from another supplier, we compare the measured magnetic strength with that of a similar magnetic separator.

What does the inspection certificate show?

The inspection certificate shows the location and description of the magnet system. Not only do we assess the current quality and condition, but also the working process.

Flux density - measured, original and minimum values.

The minimum flux density is the most important because the efficacy of your system depends on it. We subsequently compare the data with that from past measurements. In addition, we provide an inspection report in which we include any recommendations we may have for process optimization.

The following points are part of the inspection report:

- Is the magnet placed at the correct location in the process line for optimal results?

- Does the magnet meet the standard of minimum flux density?

- What is the physical condition of the magnet system?

- Are there signs of wear?

- Is there a risk of obstruction of the product flow or machine damage?

- Is the magnet safely accessible for cleaning?

- Is the de-ironing rate optimal?

- Is the magnet strong enough?

- Is the magnet being cleaned correctly and often enough?

If there are recommendations for process optimization, we add them to the inspection report.

Do you have any questions or would you like an appointment for a magnet inspection? Call +31 (0)40 221 3283 or e-mail: service@goudsmitmagnets.com.

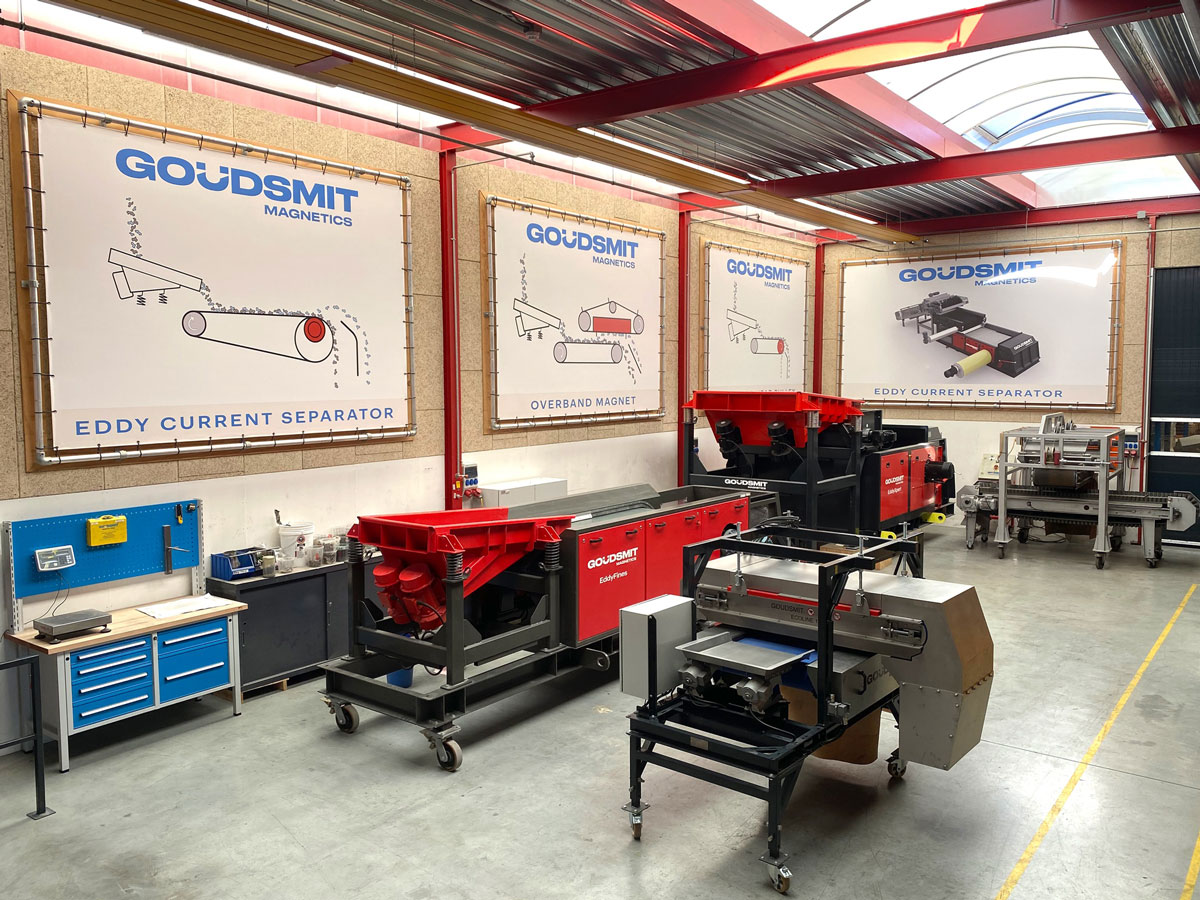

Test lab for magnet measurements

Testing can be complex, costly and time consuming. That’s why we have set up a special lab with various test facilities and equipment. In addition, our service engineers can visit on site to test the operation of the magnets in the process line.

With extensive experience and knowledge of magnets, we collect the right information about the operation of the magnet system in your product or manufacturing process. The specially designed test programme reduces the amount of time spent on and the cost of testing.

To save costs and time, we only test what is applicable to certain magnet systems and types. The result is a report that shows whether the product meets the requirements. For audits, this inspection certificate is a requirement.

Please contact our service department for a magnet inspection appointment. Call +31 (0)40 221 3283 or e-mail: service@goudsmitmagnets.com.