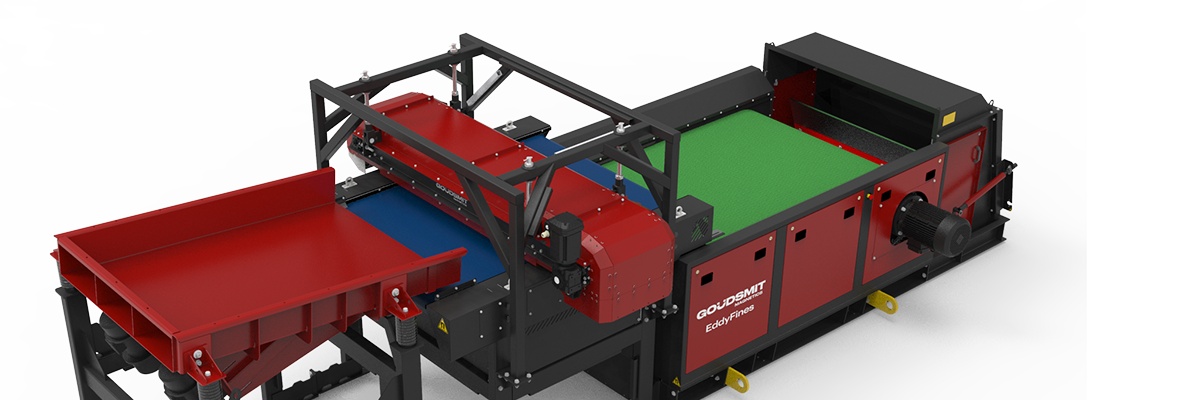

At IFAT in Munich (Hall B6-316), we will introduce a three-stage metal separator for plastics recycling, among other applications. This completely new concept consists of an Eddy-Current separator equipped with overband magnet and high-gradient head roller magnet. In one run, the system removes steel, very fine iron and stainless steel, as well as non-ferrous metals such as copper, aluminium, brass, precious metals and lead. Even metal-contaminated particles are separated from the product flow. The result of this integrated module is a cleaner and more marketable final fraction for plastics processors. Lower contamination levels in the granules or flakes reduce costs in the downstream process; filters of melting screws and installations for chemical processing of plastics remain clean and do not jam.

Adaptable modular system for plastics, WEEE and ASR recycling

This high-quality 3-in-1 metal separator is designed for fine materials from 0 to 15-20 mm.

It is particularly applied in plastics processing, but WEEE and ASR are also important applications where this magnetic technology can extract more valuable metals from the product stream. In this case with recovery as the goal instead of removal of metal contamination. We chose a combination with an overband instead of a magnetic drum separator because the first separation step gives a cleaner final fraction, which is more marketable. If required, this modular system is also available without an overband magnet.

Three-stage separation for optimum performance

The material is fed wide and in a thin layer via a vibratory feeder. This monolayer facilitates further processing of the product flow. Then the overband magnet takes effect. This separates coarser steel particles from the material. The high-gradient head pulley separator removes fine iron particles plus stainless steel, including trapped steel and stainless steel particles, after which the 38 HI Eddy current separator separates the non ferrous metal parts, even if they are attached to rubber or plastic, for example. The thinner layer thickness as well as the pre-separation by the overband magnet allow the separators to do their job better. The combination of these three different separation techniques allows recyclers to create more value by being left with a cleaner end product, which is more efficient to process and therefore more profitable. Ultimately, this results in more intensive metal separation and thus greater recovery of valuable metals.

For more information please use the contactform