Challenges in the packaging industry

The use of recyclable packaging requires efficient processes. You want flexible, automated packaging lines that can be easily converted to other product variants.

And the rising costs of transport and logistics require a reduction of packaging volumes.

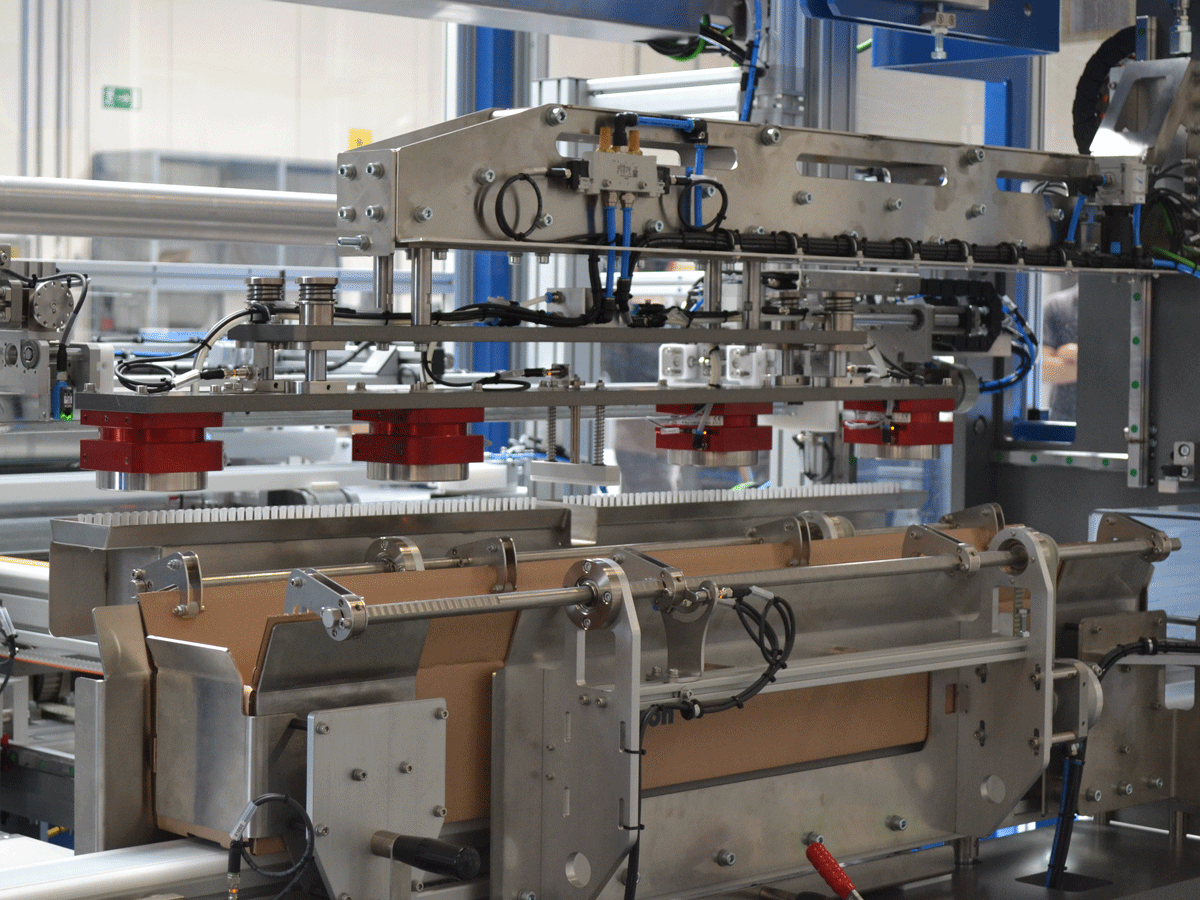

Gantry with magnetic grippers for handling and packing steel profiles

Less manpower due to automation

On a global scale, the packaging industry can only be successful with efficient packaging methods, with minimal labour costs. This can be done by automating repetitive work. Magnetic force is ideal for packaging cans, jars with steel lids and fasteners.

Palletizer on robot arm

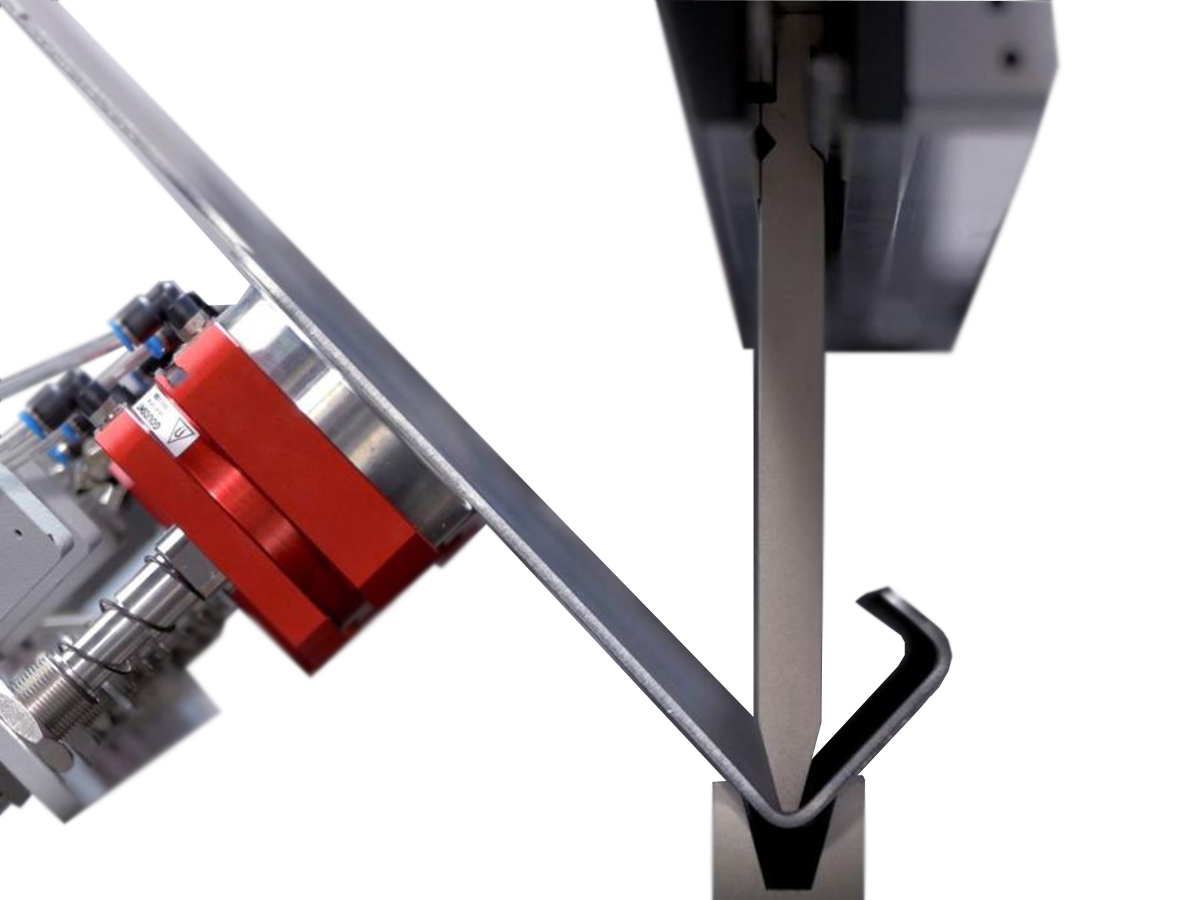

Reduce packaging volume through magnetic alignment

Transporting empty space is a waste. This often happens when depositing long steel products in boxes, such as nails and fasteners.

A magnetic field allows you to orient and align these products neatly. This reduces the packaging volume by at least a factor of 3.

We are happy to use our specialist skills to help you

Take advantage of our many years of experience and know-how to face today’s challenges together.

Our mission is to be the best partner for magnetic solutions, in order to realise the ideal packaging line together with you.

Palletizer for canned pet food

Shorter cycle times through automation with magnetic force

Magnets offer surprising solutions for handling and transporting packaging with ferromagnetic properties, such as cans and jars with steel screw caps.

When developing magnetic modules and components, our engineers pay close attention to optimising magnetic force with the ideal magnet composition.

Our specialists design and build a magnet system for you that meets your requirements with regard to acceleration forces, cycle times and accuracy.

Fulfilling safety requirements

Safety is always a top priority in automated processes. To provide your employees with a safe working environment, it is essential to use reliable machines and production equipment.

Goudsmit pays a lot of attention to safety when developing machines and equipment, in accordance with the Machinery Directive.