Cleanflows - manual cleaning - rotating

Especially suitable for magnetic filtering of small amounts of ferrous contaminants from poorly flowing - e.g. fatty - powders in free-fall transport pipes. Rotation of the magnetic bars prevents bridging and blockages.

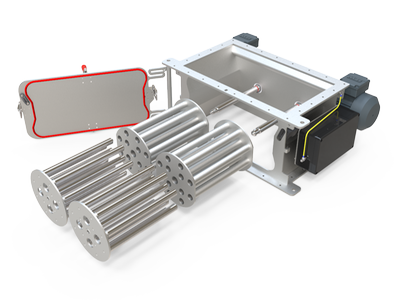

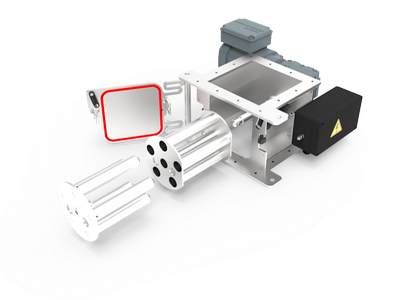

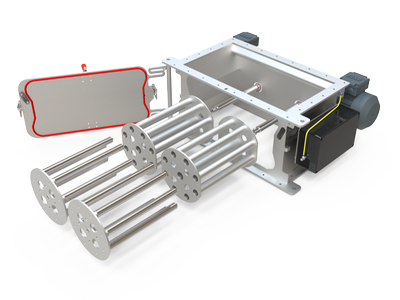

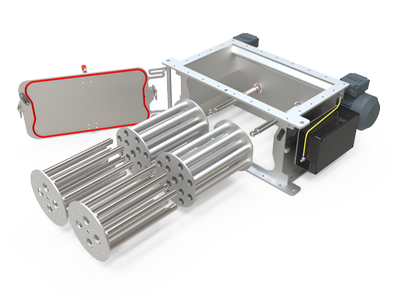

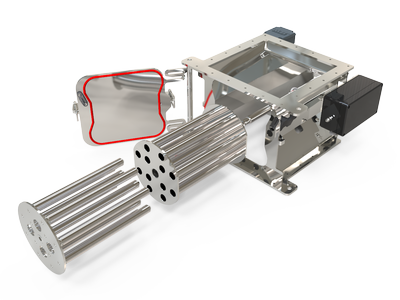

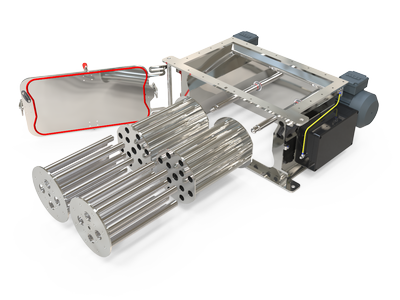

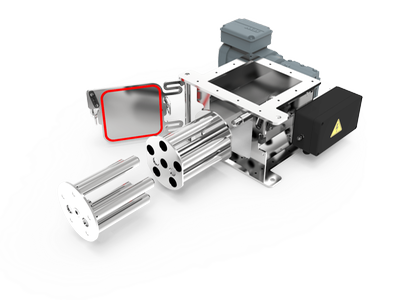

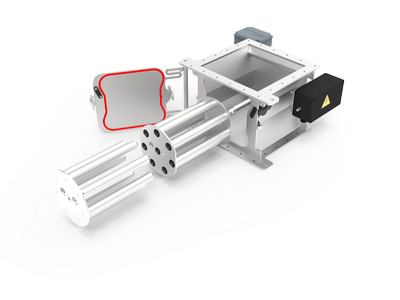

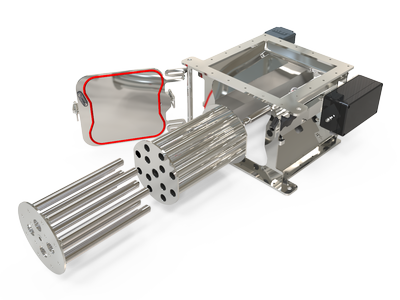

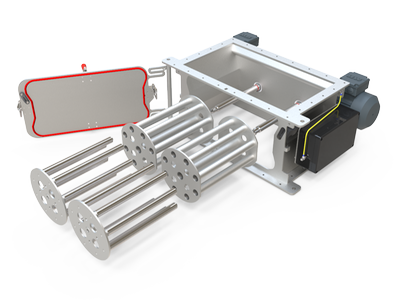

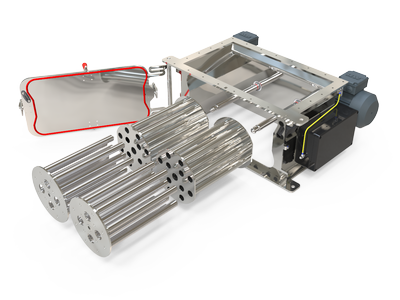

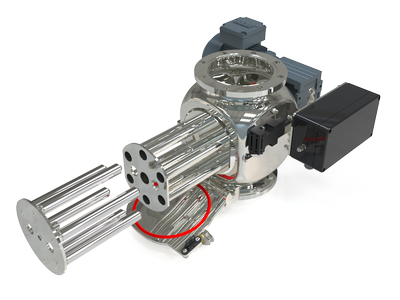

- 1 or 2 rotors with magnetic bars

- Magnetic bars in extractor tube (Max. 13,000 gauss)

- Capacity 9 - 45 m³/h

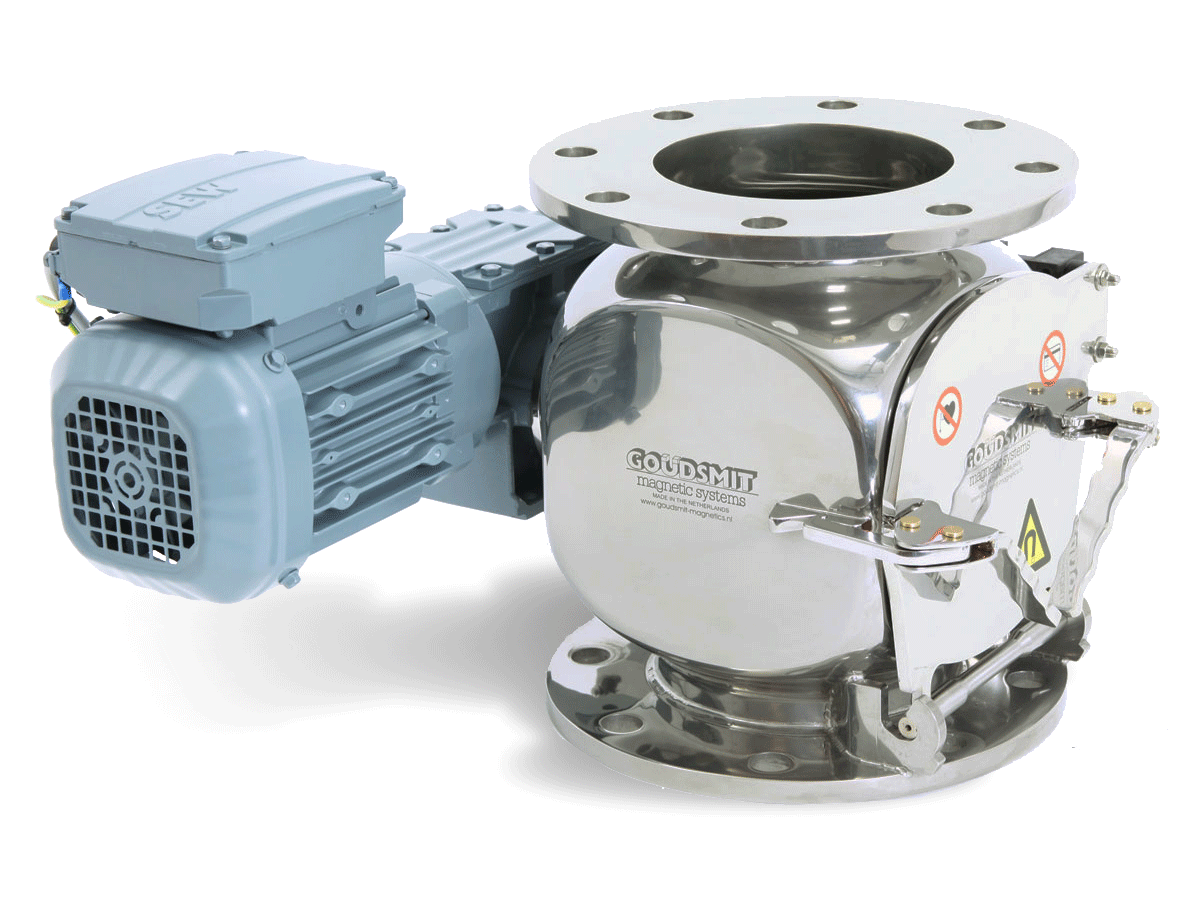

- Types basic/food/pharma

- ATEX II 1/2 D possible

Poorly flowing powders in free-fall pipes

These rotating Cleanflow magnetic separators are specially suited for poorly flowing powders. The rotating magnetic bars prevent bridging and in the end blockages or clogging (see also 'Working principle').

The 'Basic' versions are suitable for so-called non-food applications; the hygienic 'Food‘ / 'Pharma' versions are suitable for food and pharmaceutical industries with a danger for bacterial growth.

Construction & materials data

Summary of specifications

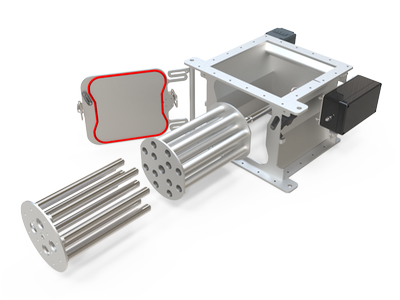

- Multiple magnetic bars mounted in a rotor.

- Extractor bars for 'quick cleaning'.

- Magnet quality: neodymium.

- Removable rotor on a shaft, driven by an electric motor.

- Materials - in contact with product: AISI316(L).

- Door with robust hinge that is held shut with quick-release clamps.

- Sturdy silicone EC1935 / FDA door gasket.

- Steute door safety switch - switches the motor on/off when the door is closed/opened.

Available accessories, version & options

Online available accessories & spare parts

Click on a product variant to find the online available accessories & spare parts.

Versions:

- Basic types are suitable for non-food applications - without danger for bacterial growth.

- Food types are suitable for food and pharmaceutical applications where there is a risk of bacterial growth.

- Pharma types with hydroformed housing are suitable for food and pharmaceutical environments where there is a very high risk of bacterial growth. This type has smooth, sloping surfaces and rounded corners without welds.

- ATEX: food and basic types have ATEX and non-ATEX versions, farma types are all ATEX. All ATEX versions are certified according ATEX Ex II 1/2D.

Options:

- Versions for high temperatures (to 140°C) - not available in combination with ATEX

- White door seal instead of red

- Inlet/outlet adapter pieces from square to round

- Extra strong magnets

- Interface signals: Analogue contact for connection of PTC resistor

Option for type Pharma:

- Counter-flanges

Filtering & discharging of ferrous contaminants

How does the magnetic filtering work?

The magnetic rotor with very strong neodymium magnetic bars is positioned in the middle of the product flow. The product with ferrous contaminants passes several magnetic bars while flowing through the separator.

The magnets attract passing ferromagnetic contaminants. The captured particles stick to the magnets, while the purified product flows further.

Because the rotor rotates inside the housing, the product continuously falls off the bars. This prevents 'bridging', product accumulation and ultimately blockages. Moreover, the magnetic filtering capacity remains optimal, because the magnetic bars remain clean.

How does the cleaning / iron discharging work?

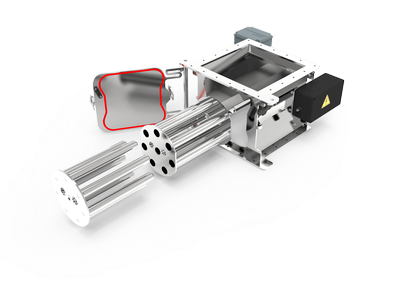

After you have stoped the product flow, you can take the entire magnetic rotor unit out of the product channel.

Then you can pull the magnetic bars out of the extractor tubes, causing the ferrous particles to fall off the extractor tubes.

Cleaning / iron discharging sequence

- Stop the product flow.

- Loosen the fastener clamps.

- Take the complete magnet unit out of the housing.

- Take the magnet unit out of the extractor unit and place it away from the extractor unit on a clean surface.

Catch the ferrous particles that now will fall off the tubes and dispose them. - Wipe clean all parts with a soft cloth and - if necessary - a suitable cleaning fluid.

- Shove the magnet unit back into the extractor unit.

- Place the complete magnet unit assembly back into the housing.

- Tighten the fastener clamps.

- Restart the product flow.