Flat pot magnets

Flat pot magnets are available in neodymium, samarium cobalt and ferrite. These magnets are suitable for gluing.

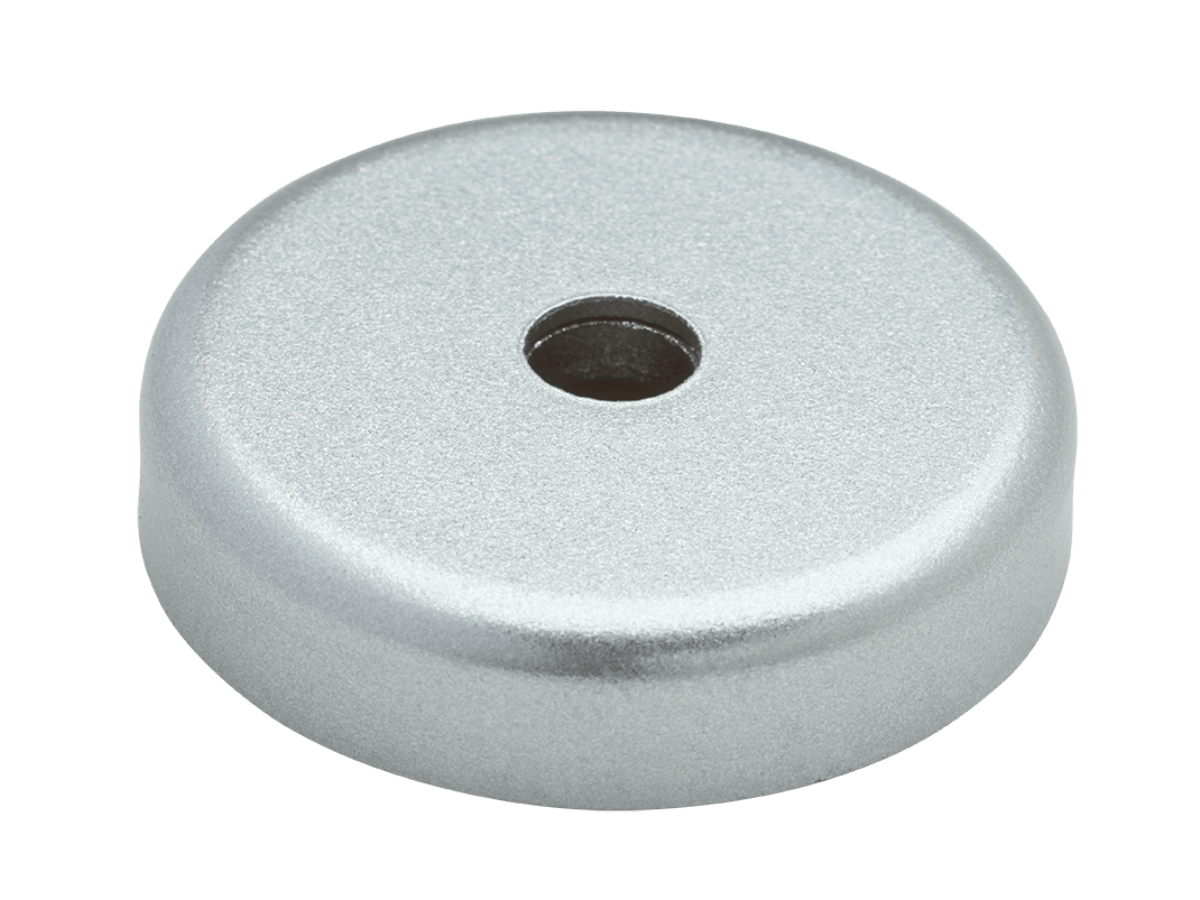

Pot magnets with countersunk hole

A bolt with a flat countersunk head falls flush with or in the top of the magnet. This optimizes the attracting surface of the pot magnet.

Pot magnets with cylinder hole

These pot magnets are screwable at a high torque while the magnet remains unloaded.

Pot magnets with internal thread

For easy installation in places with low installation height. When mounted, the pot magnet remains unloaded.

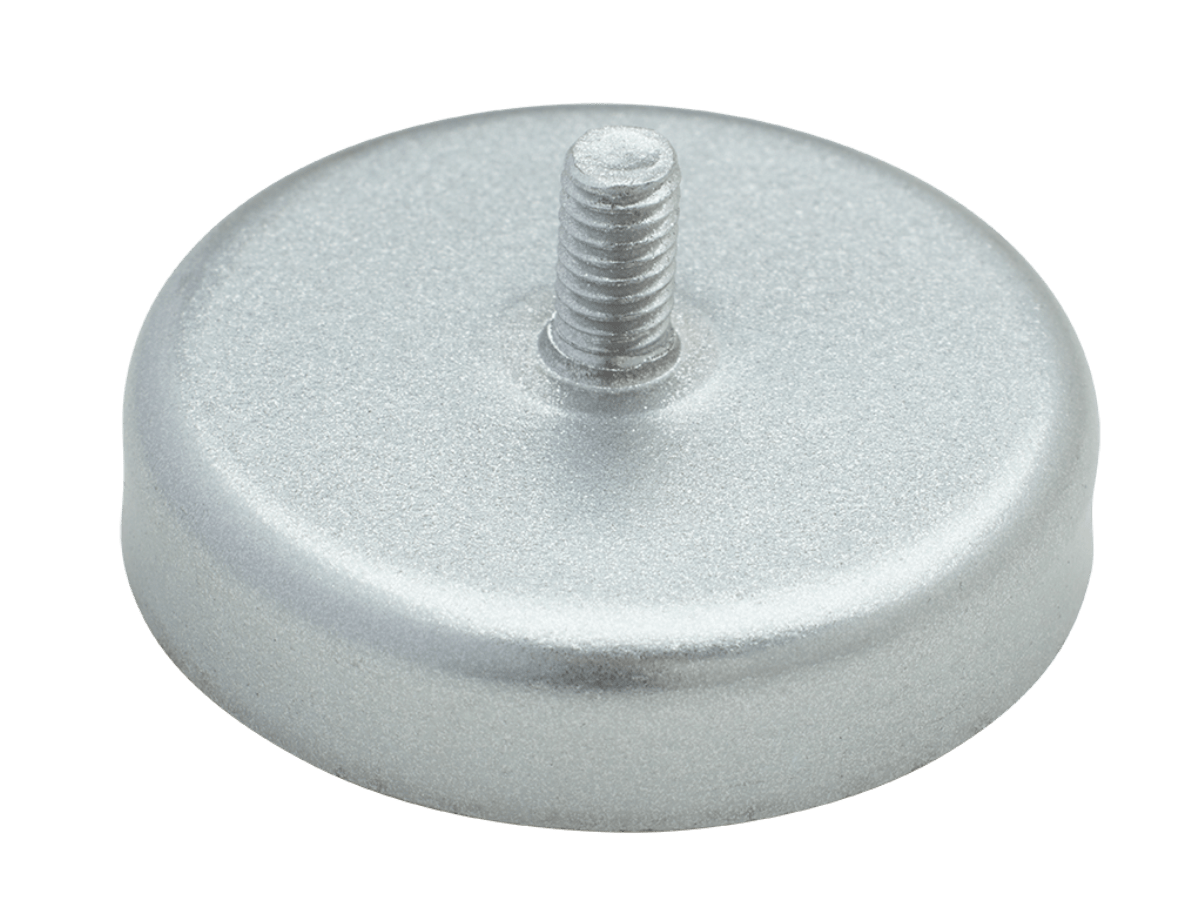

Pot magnets with threaded end

Compact magnet systems with a steel shell and a threaded end for easy mounting.

Pot magnets with threaded bush

Compact magnet systems with a steel shell and a threaded bush for easy mounting.

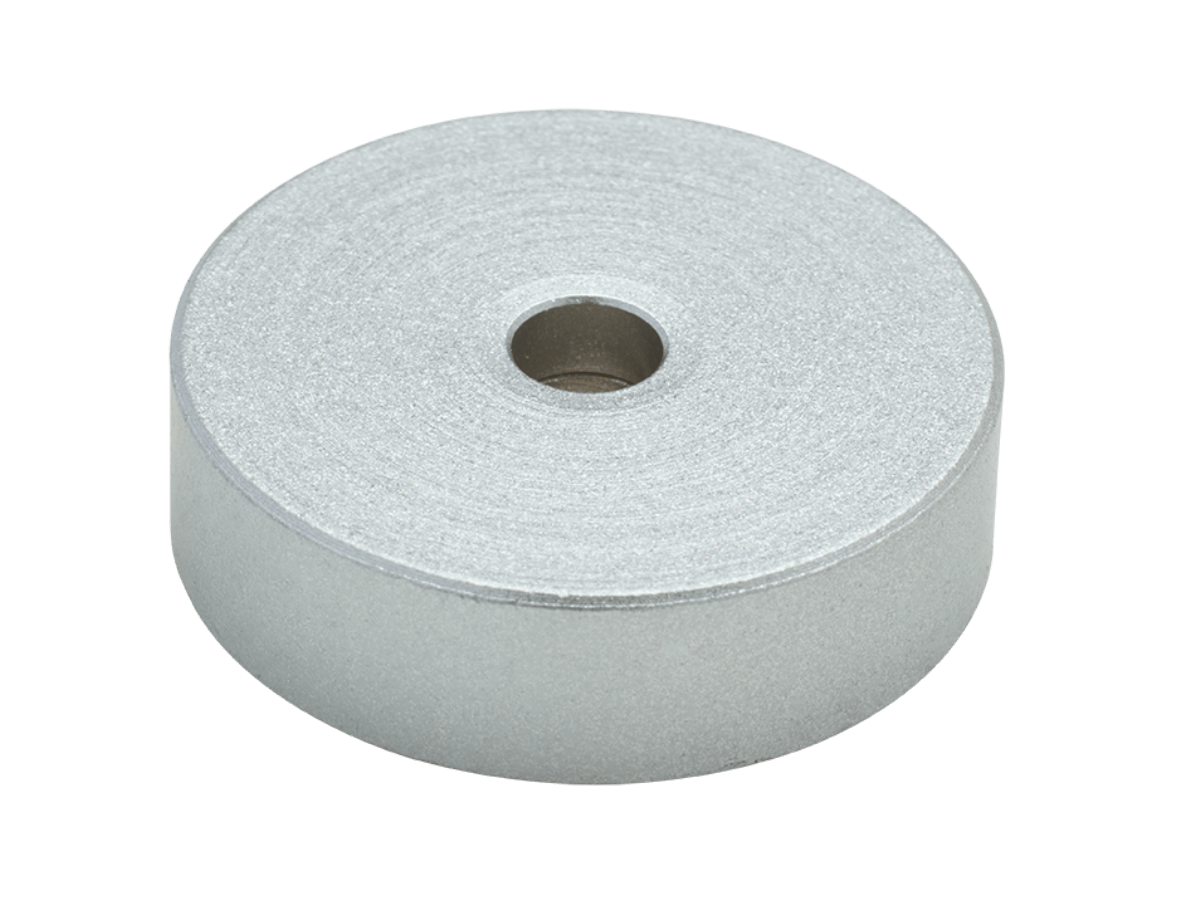

Pot magnets cylindrical

Pot magnets with fit tolerance h6-h9 are suitable for gluing, pressing and shrinking.

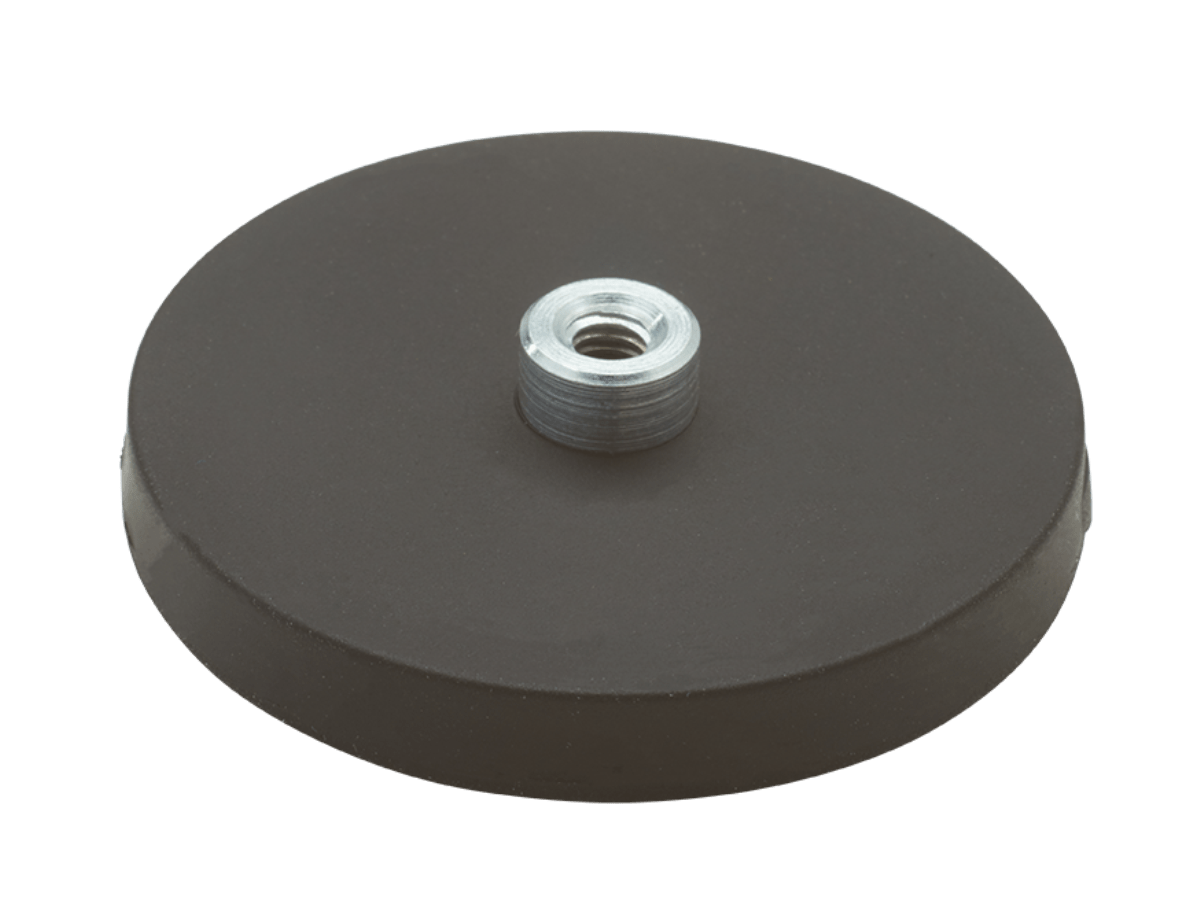

Rubberized pot magnets

With rubber coating for more shear force. Perfectly suited for easily damaged surfaces to prevent scratches.

Electro holding magnets

Electromagnets can be switched on and off. Used to pick up, position and hold products.

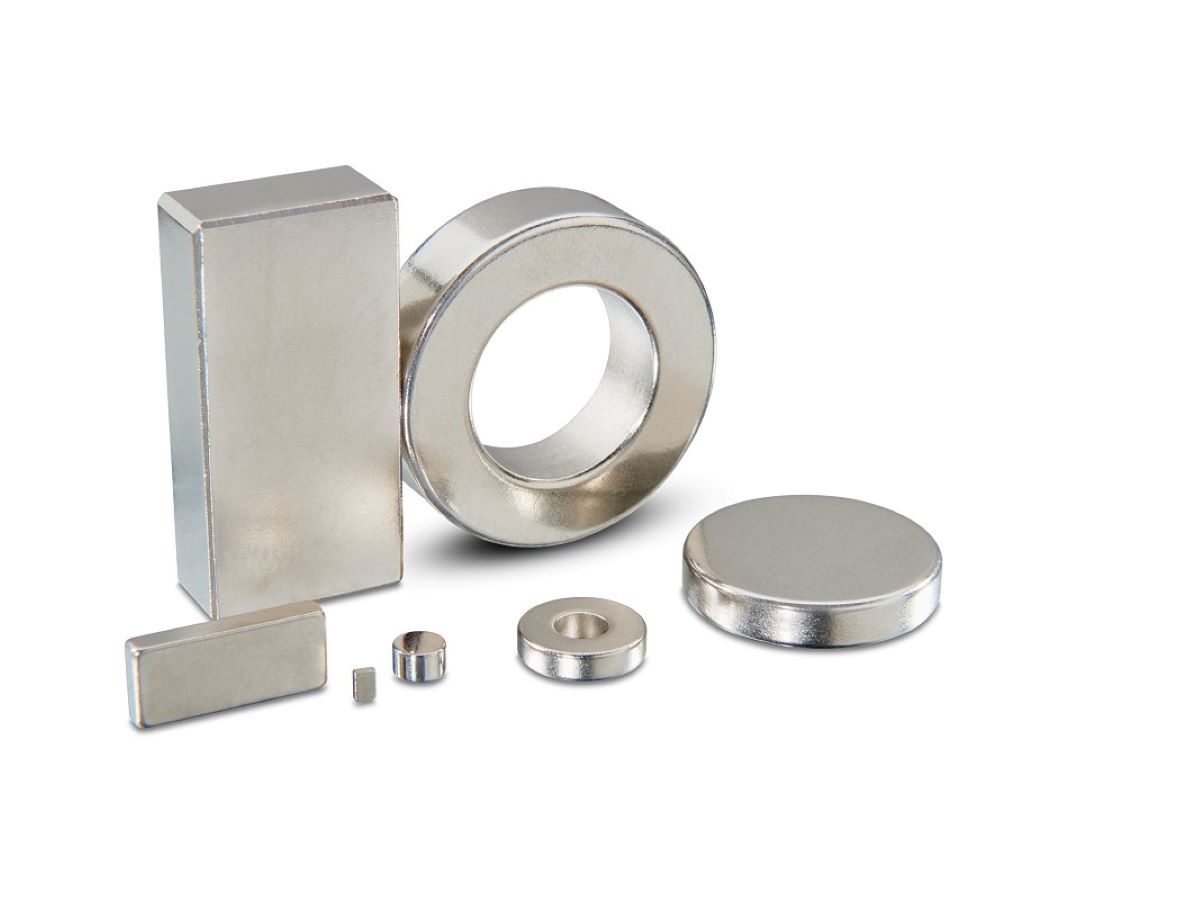

Neodymium - NdFeB stock magnets

If you need a permanent magnet that is small, lightweight and super strong.

Pot magnets and round electromagnets of high quality

Compact magnetic systems with a shell of steel, brass, high-grade steel or plastic. The shell prevents dispersion of the magnetic field and increases the magnetic force of the attracting surface. The shell - or pot - also provides better corrosion and chemical resistance. The maximum operating temperature ranges from 60 to 450 °C.

Pot magnet materials

Pot magnets are available in the following materials:

- neodymium (NdFeB)

- samarium cobalt (SmCo)

- AlNiCo

- ferrite (FeB)

The maximum application temperature ranges from 60 to 450 °C.

Installation options

Pot magnets and electromagnets are available in various designs: flat, threaded bush, threaded stud, countersunk hole, through hole and threaded hole. The many different models mean there is always a suitable magnet for your application.

Conditions for optimum holding force

Clean pole surfaces and a flat workpiece ensure optimal magnetic holding force. The specified holding forces are measured under optimum conditions: perpendicular, on a piece of grade 37 steel that has been ground flat to a thickness of 5 mm, without air gap. Small cracks in magnetic material have no effect on the pull force.

In principle, pot magnets retain their magnetic strength indefinitely if not exposed to these four factors (see 'Does a magnet lose strength over time?')