With FEM simulations & magnet calculations, we design the best magnet system for you. We combine your concept with our magnet knowledge and thus accelerate your innovation and development process. This saves you valuable time. In the new white paper, you can read all about FEM calculations for Hall sensors, among other things.

Using FEM calculations (finite element method), our engineers simulate magnet assemblies, both in 2D and 3D. Applying simulations and calculations at an early stage prevents design errors and gives you direct insight into the operation of your prototype and end product. This speeds up your time-to-market, saves you money and gives you certainty about the operation of a magnet or assembly even before the prototyping phase.

With FEM simulations:

- Accelerate your time-to-market

- Gain quick insight into the operation of a prototype, magnet or assembly

- Prevent design errors

- Saves you time and money

FEM optimises magnetic performance

Magnetic materials such as Neodymium are expensive. This makes it extra important to make the best use of the magnets. FEM calculations and simulations plus our years of experience and knowledge of magnetism, ensure that we can accurately predict how the magnet will behave in terms of:

- Depth of the magnetic field

- Peaks and troughs of the magnetic field over a surface

- Maximum force of the magnet on another ferromagnetic object

- Present 'residual magnetism' when switching magnets on and off

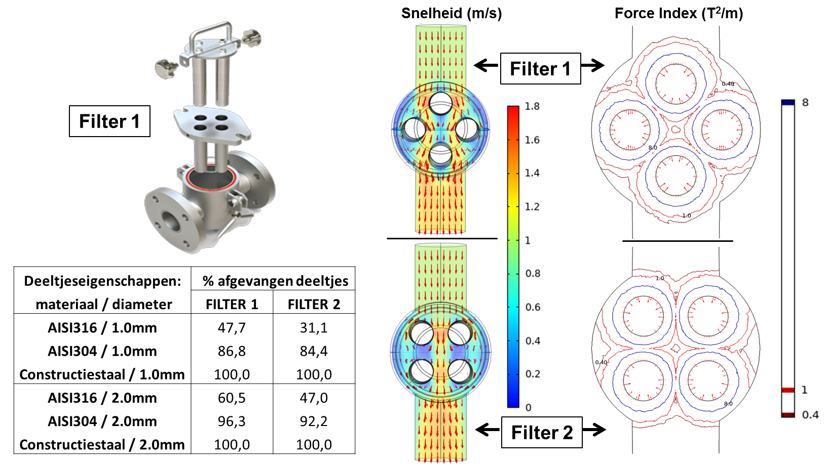

- Separation of particles from a product stream of, for example, powder or liquid.

Also read the blog: FEM calculations prove magnetic force

More information? Please use the contact form