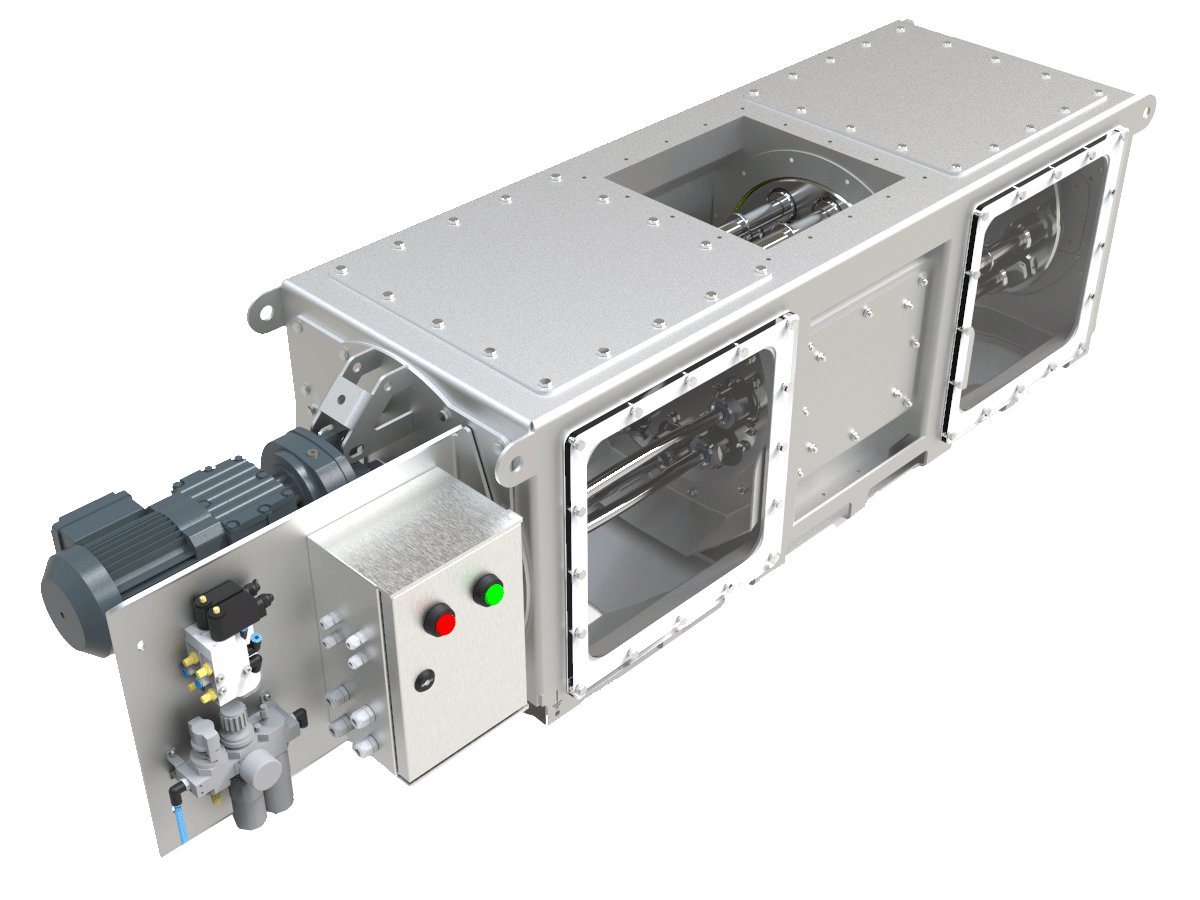

Cleanflows - automatic continuously cleaning - rotating

This is the only rotary Cleanflow type that does not require a production stop to discharge the filtered ferrous contaminants. Due to the automatic time-controlled discharging of ferrous particles, it is suitable for product flows with a relatively much ferrous contamination.

Suitable for poorly flowing - like sticky - powders in free-fall transport pipes.

The automatically controlled discharge of trapped ferrous particles makes these magnetic separators suitable for situations where they are hardly or not accessible for operation.

- Continuous automatic cleaning

- Rotor with magnetic bars

- Magnetic bars in pneumatic tube (Ø34 mm, 9400 gauss)

- Capacity up to 60 m³/h

- ATEX II 3D possible

Sticky powders with relatively many ferrous contaminants

The rotating, automatically cleaned Cleanflow magnets are very suitable for poorly flowing - like fatty - powders that contain relatively many ferrous contaminants, and / or for less easily accessible installations.

Construction & materials data

Click on a product variant to find the data sheet, drawings and other downloadable product information.

Short description

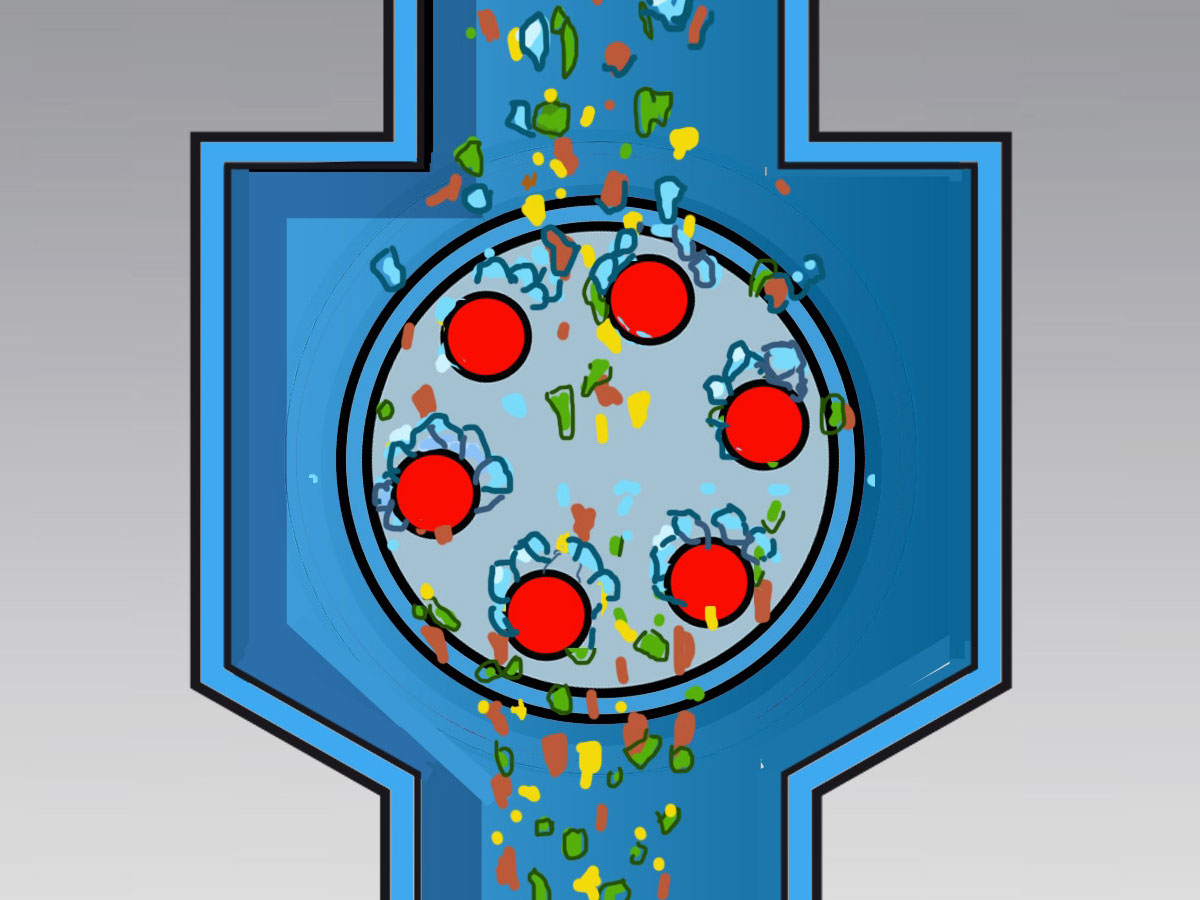

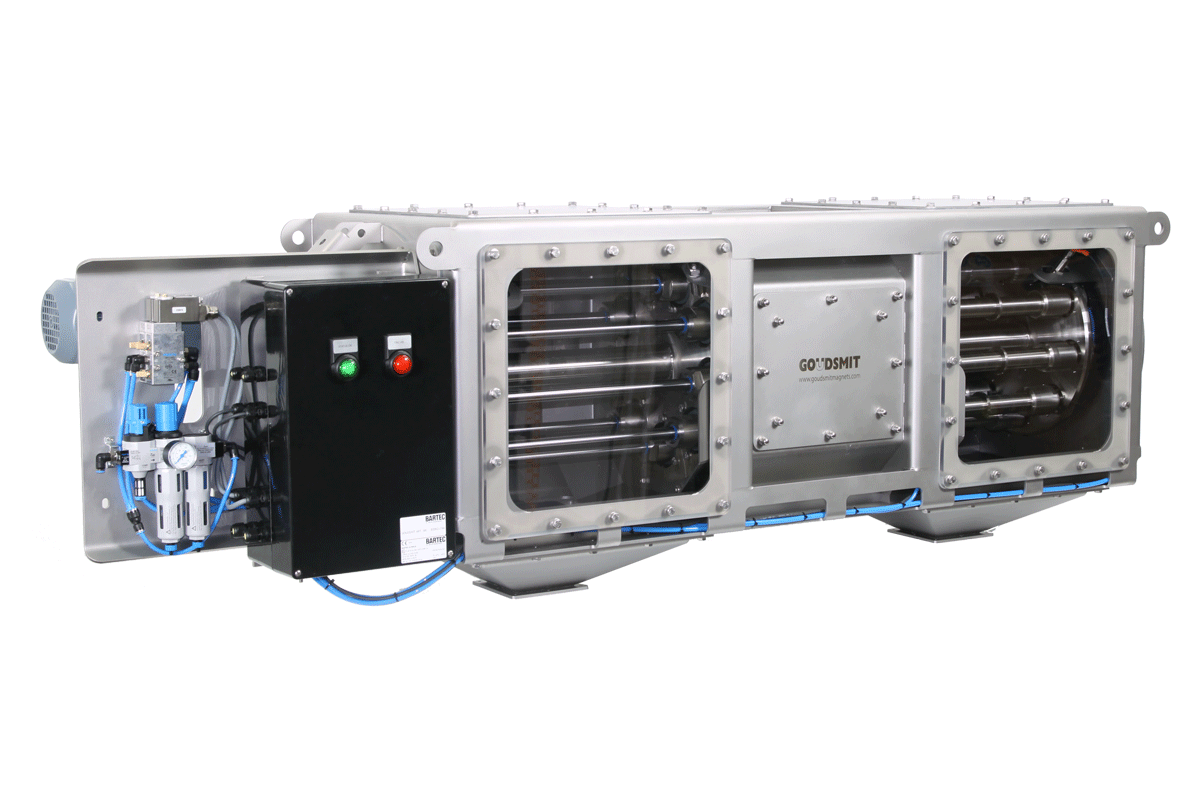

These automatic Cleanflow magnetic separators have a magnetic rotor. This rotor contains pneumatic magnetic bars, constructed of robust Ø34 mm SS tubes inside of which strong neodymium N42 magnet packages are moved by air pressure. The bars measure no less than 9400 gauss on the Ø34 mm tubes.

Summary of important specifications

- Siemens LOGO! PLC control

- Ø34 mm pneumatic operated magnetic bars

- Magnet quality: neodymium N-42, 9400 gauss on the Ø34 mm tube

- Material housing and rotor: AISI316 / AISI316(L)

- Finish: grit blasted

- Material gaskets in product channel: silicone, acc. EC1935 / FDA

Online accessories & spare parts

Click on a product variant to find the online available accessories & spare parts.

Filtering & discharging of ferrous contaminants

How does the magnetic filtering work?

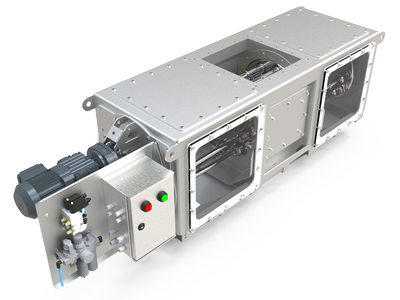

The magnetic rotor with very strong neodymium magnetic bars is positioned in the middle of the product flow. The product with ferrous contaminants always passes multiple magnetic bars while flowing through the separator.

The magnets attract passing ferromagnetic contaminants. The captured particles stick to the magnets, while the purified product flows further.

How does the cleaning / iron discharging work?

- Production can continue during cleaning, because the magnetic bars of these Cleanflows are horizontally fixed inside the product channel. As a result, magnetic contaminants can never pass.

- The pneumatic tubes enclosing the magnetic bars are horizontally fixed positioned in both the product channel and - in turn - in the left and right side chutes for iron particle discharging.

- After you have given the start signal for an iron particle discharge cycle, the tubes slide over the magnets by air pressure to the left or right iron discharge chute.

- The retainer rings on the tubes hereby drag the trapped ferrous particles out of the product channel. Once outside the product channel, the ferrous particles fall off the tubes as soon as they are outside the influence of the magnets.

- The time interval between 2 iron particle discharge cycles can be set locally, on the PLC control on the machine, or from your central control.