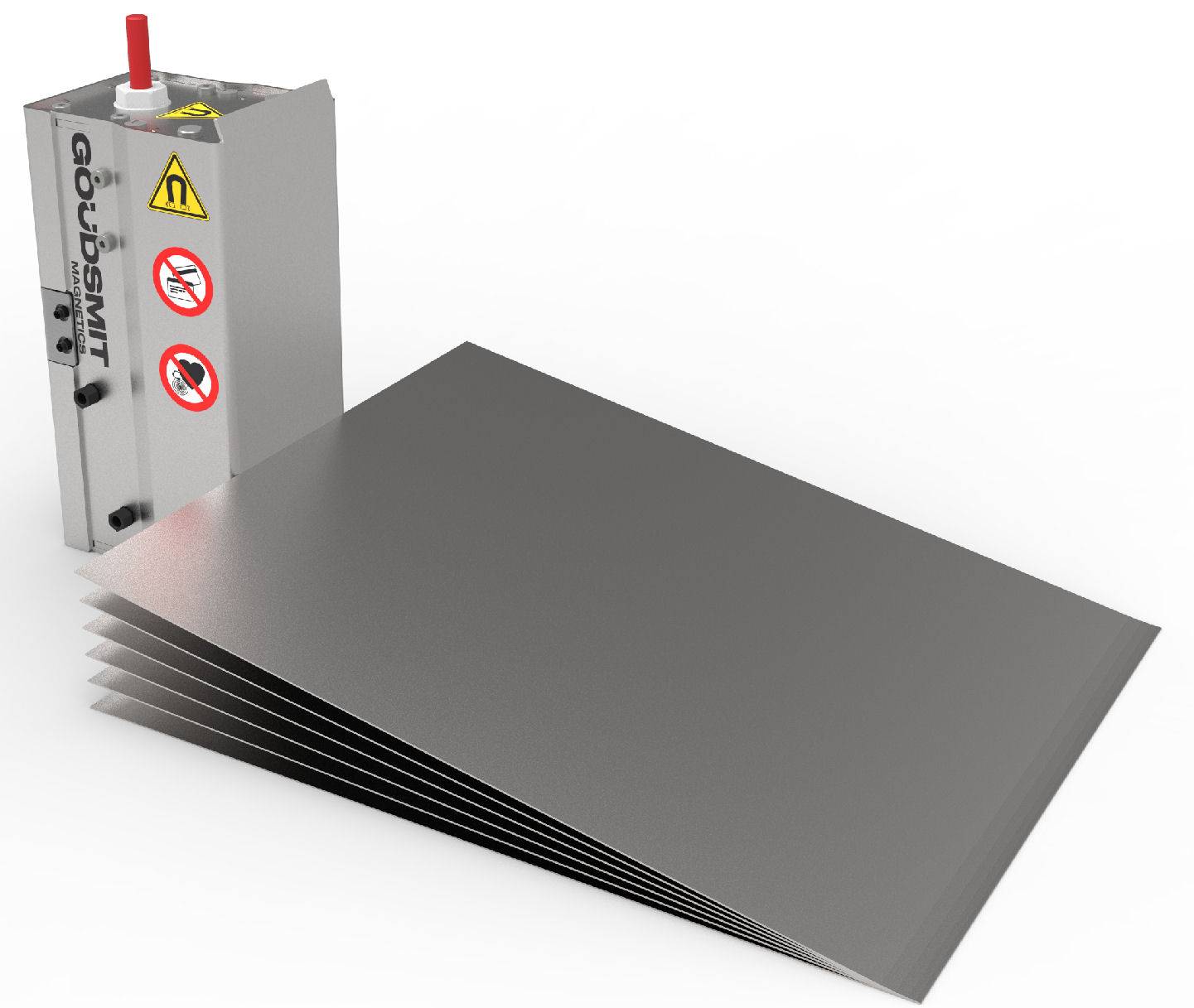

Goudsmit's recently developed 'Fail Safe' magnetic sheet separator automatically separates steel sheets up to a thickness of approximately 4 mm. The separator is equipped with extremely powerful Neodymium magnets that can be switched on and off pneumatically using a newly patented system. This switching operation occurs quickly through the rotation of the magnets. The maintenance-free sheet separator is the only one of its kind that is equipped with a spring-driven off mode.

Extra safe

The extra safe – hence the name Fail Safe - sheet separator automatically switches to the off position when there is any interruption in the compressed air flow, even with a full load at maximum stack height. During maintenance, it is also impossible for the magnet to accidentally remain switched on. That’s something you ordinarily can’t see, and it often leads to industrial accidents. With the red indicator you can see from a distance whether the magnet is switched on. This provides added safety. In contrast to fixed sheet separators, switchable sheet separators allow for an interim change of products during a set process. It is possible to separate steel sheets of almost any shape, length or width. Round or asymmetrical shapes are also possible. The permanent magnetic force does not decrease and is guaranteed for decades.

Automated processes

In addition, this system, in combination with a swivel arm, is height adjustable. Magnetic sheet separators can be used in sheet metal processing industries and robotised cells for the production of welded assemblies. Robots pick up large sheet pieces with magnetic grippers and position them on a welding bench. Because the steel sheets are oiled, they can stick to each other, with the robot sometimes taking two sheets at the same time.

Strong neodymium magnets

As a result, the second steel sheet may detach halfway to the welding bench. This can cause a lot of damage in a high-tech environment where a welding bench is often equipped with sensors, recorders and actuators. The double insertion of two steel sheets stuck together can also cause great damage to a die. By applying Neodymium sheet separators, the sheets are separated from each other despite the film of oil, whereupon the robot can lift them one by one from the stack. The Fail Safe sheet separator also provides an option for on/off detection using a plug & play system.

Pneumatic operation

The compressed air operated sheet separators increase safety and reduce the costs of unstacking or changing a stack of steel sheets. The magnets not only separate oiled sheets, but also work well when there is a vacuum present between steel sheets, or when sheets are pre-processed or polished. In contrast to fixed sheet separators, switchable sheet separators allow for an interim change of products during a set process.

When the top sheet is removed from a stack, the bottom sheet immediately takes its place. In order to replenish a stack of steel sheets, the magnetic sheet separators can simply be turned off with a pneumatic valve. After releasing the swivel arm, the magnets turn away, after which a stack of sheets can easily be changed or replenished.

More information? Please use the contact form