Undesired metal particles in milk and dairy

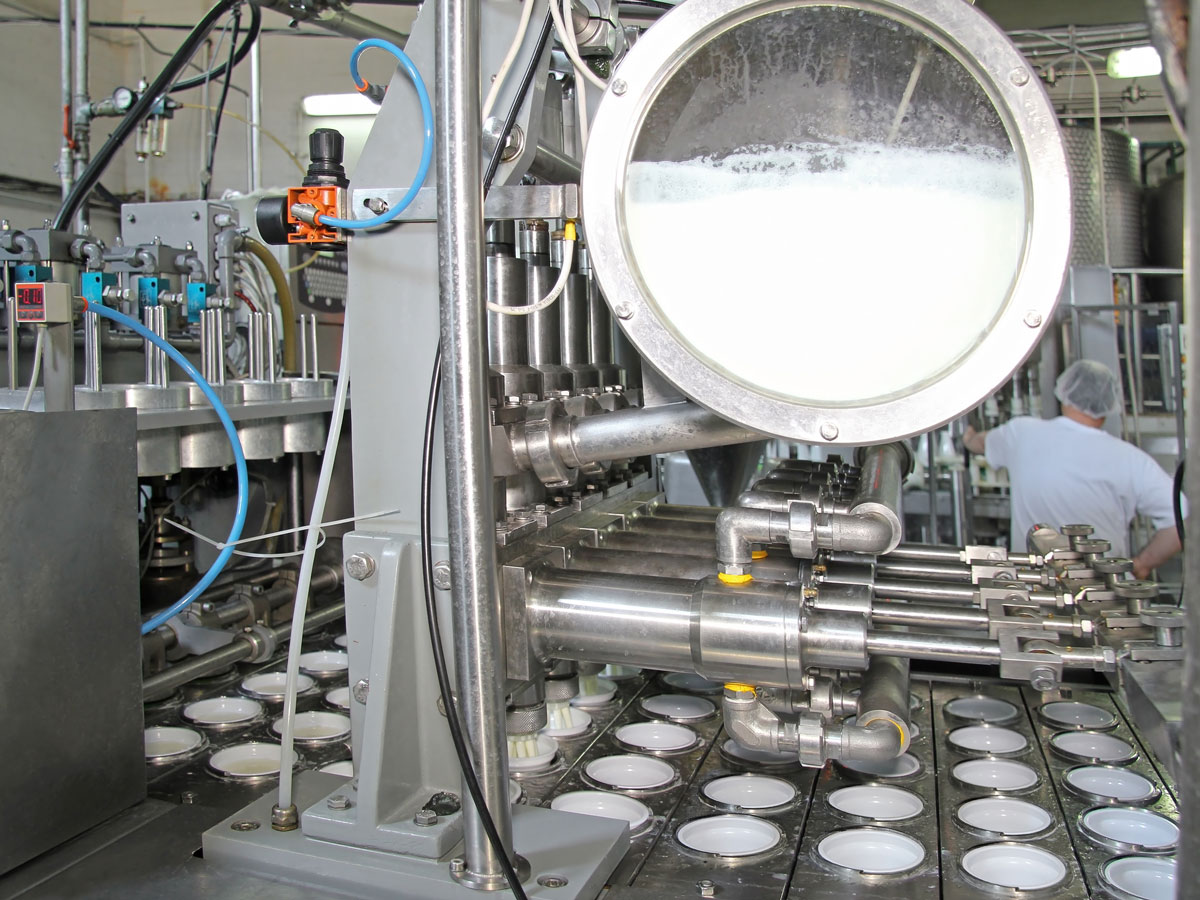

During the processing of milk into milk powder, whey powder or lactose, metal particles sometimes end up in the product flow. This happens during the pumping of the milk, or due to remnants left behind as a result of maintenance work. Sometimes particles come loose as a result of corrosion, for example due to temperature changes in the spray dryer. A contaminated input of materials or machine wear also causes metal pollution in milk powder and dairy.

Failure to remove these undesired metal parts in time reduces the quality of your end product and results in damage claims and product recalls.

Metal contamination in milk powder on magnetic bars

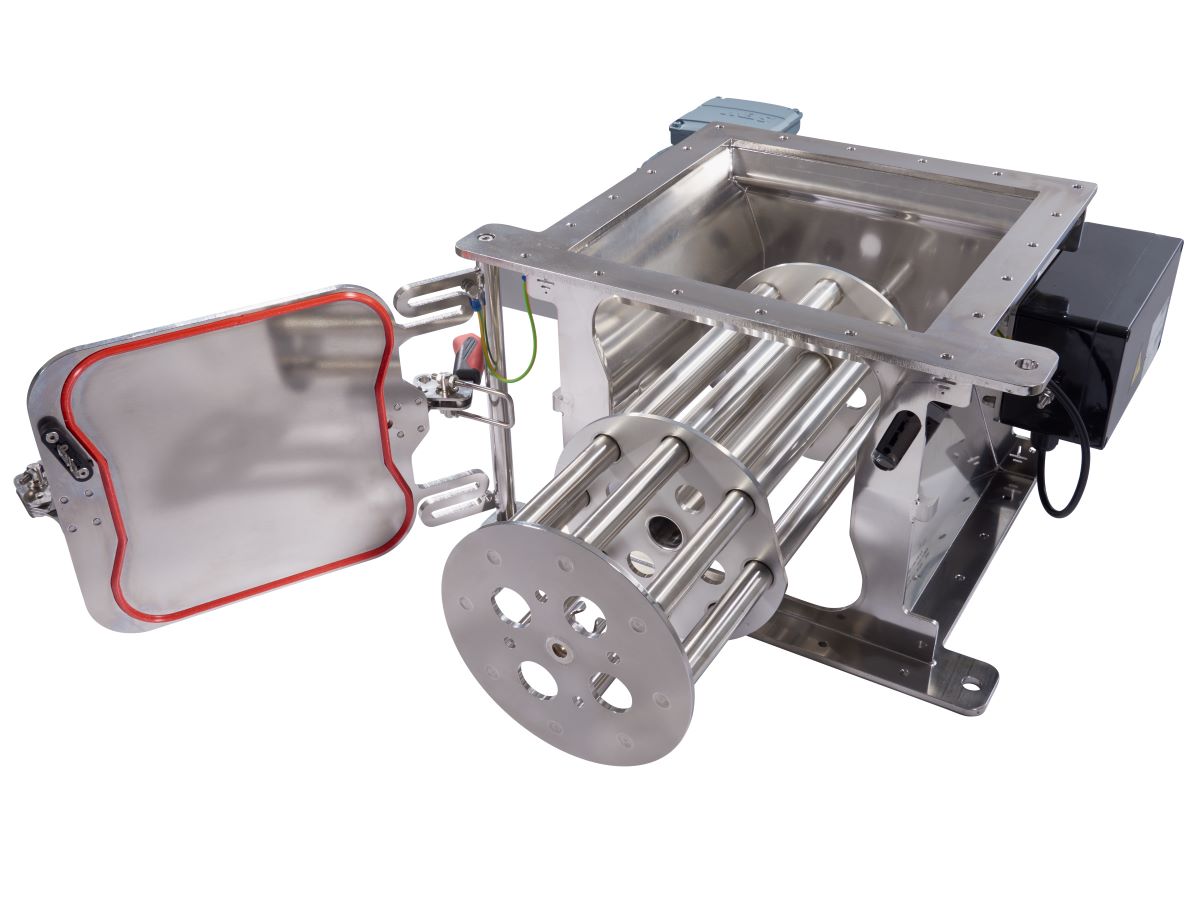

Hygienic version & quick cleaning

Goudsmit’s magnet systems are specially designed for the high hygienic requirements in the dairy industry. They have a rounded shape with a smooth finish. Due to the presence of a (semi-)automatic extractor, the trapped metal parts can be removed quickly and easily.

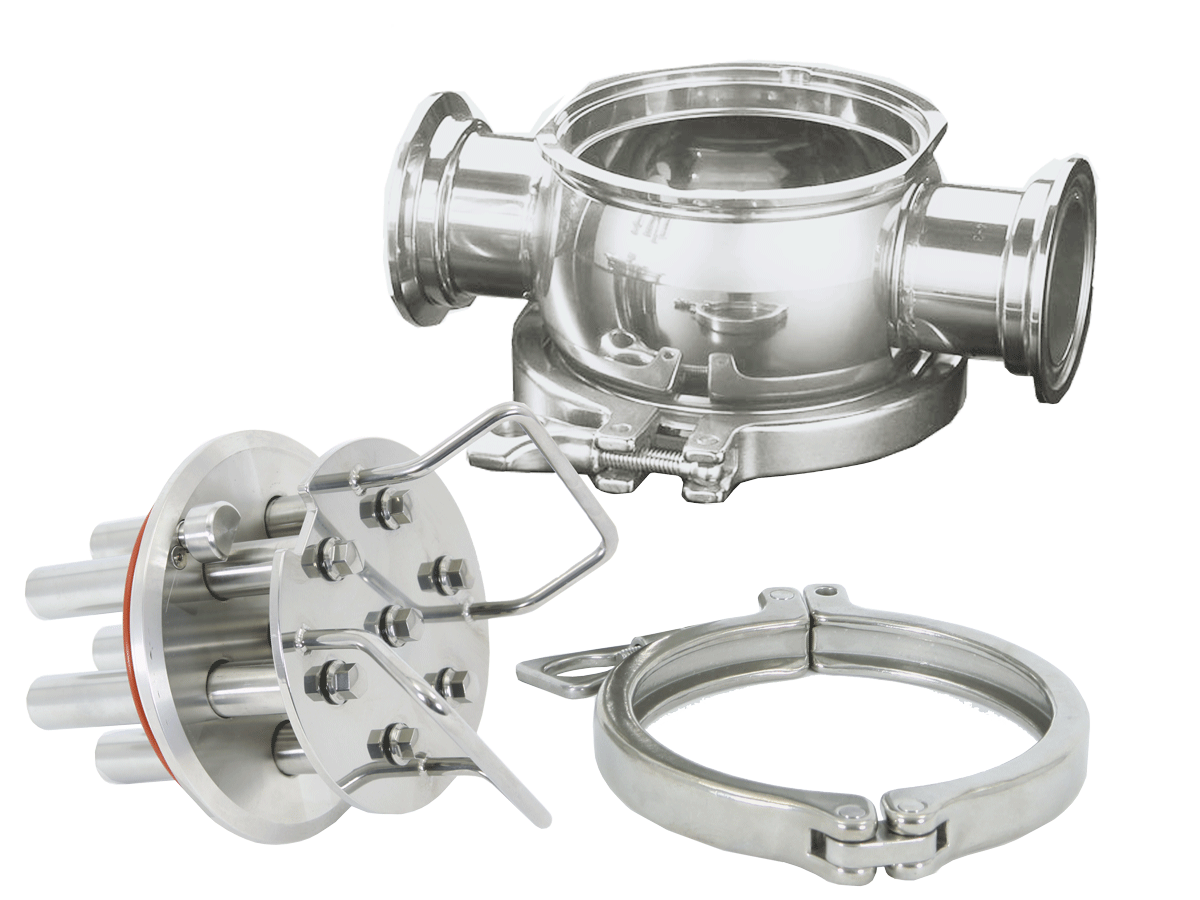

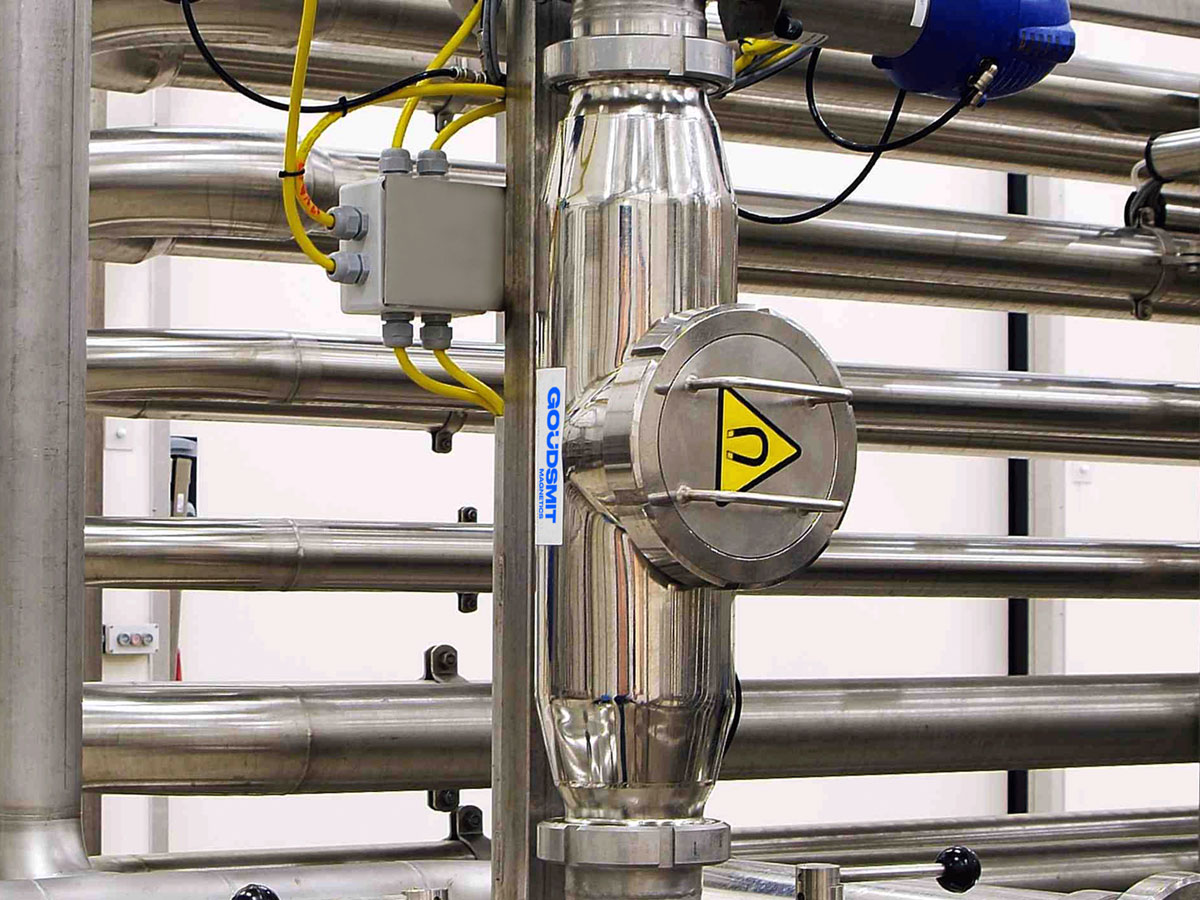

Magnetic filter in a fluid line

Efficient separation of iron and stainless steel particles from liquids

From liquids such as milk, butter or whey, you can separate smaller parts than from powders. This is apparent from tests and from practice. For these liquids, we have developed magnetic filters in industrial and hygienic versions. The EHEDG certified magnetic filters and filters with CIP/SIP (Clean-in-Place, Sterilising-in-Place) cleaning prevent bacterial growth. They are easy to clean, even in hard-to-reach places. Moreover, the magnetic filters are made of stainless steel 316 and have a smooth finish according to HDN (Hygienic Design Network) standards.

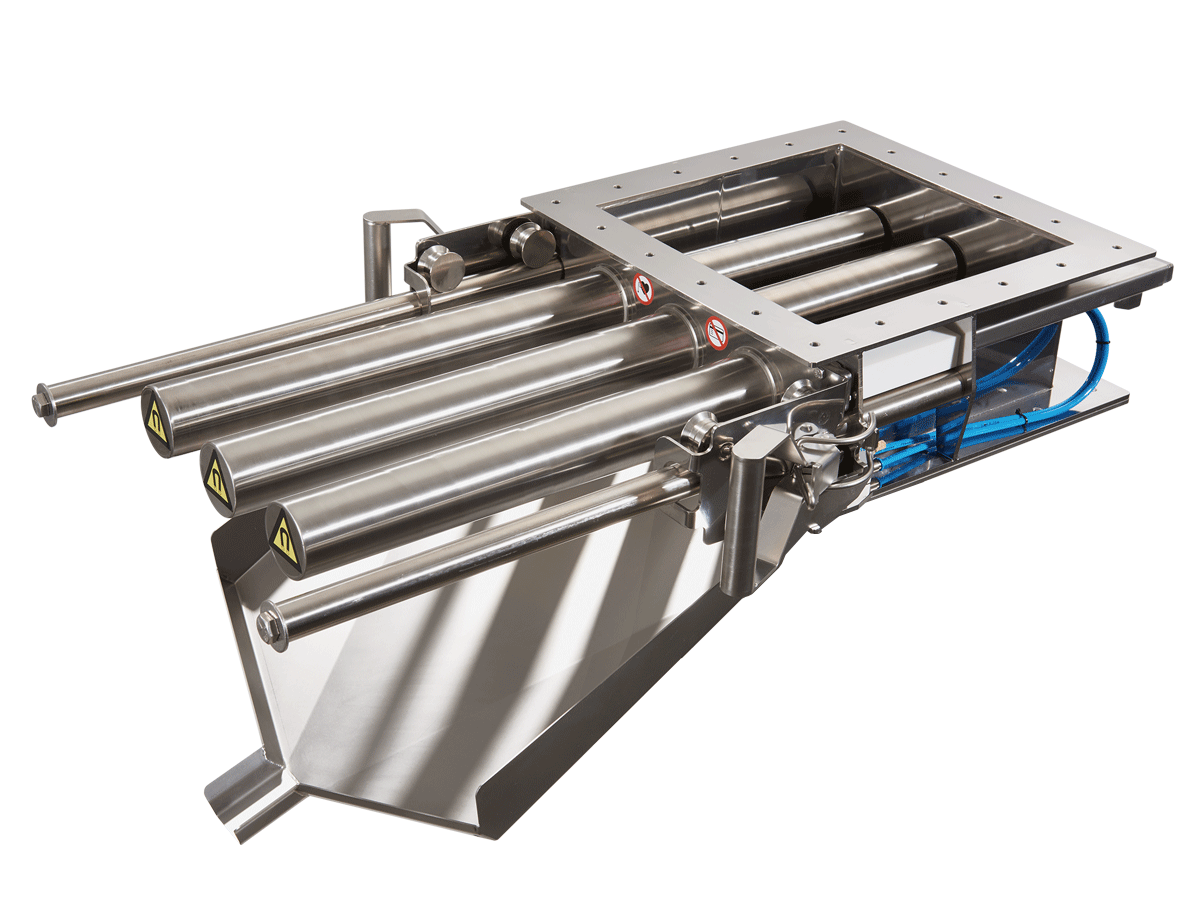

Strong magnetic separators remove undetectable iron and stainless steel parts from powder

The metal particles in milk powder are so small that a metal detector cannot see them. Goudsmit supplies powerful magnetic separators that are able to capture these small particles from around 30 µm. These separators contain magnetic bars that have a small but very intensive magnetic field. They separate the finest metal particles from powdered dairy products.

In addition to ferrous parts, these strong magnetic separators even capture stainless steel particles. Due to the deformation, such particles acquire weakly magnetic properties.

Separation of fine metals from sticky products

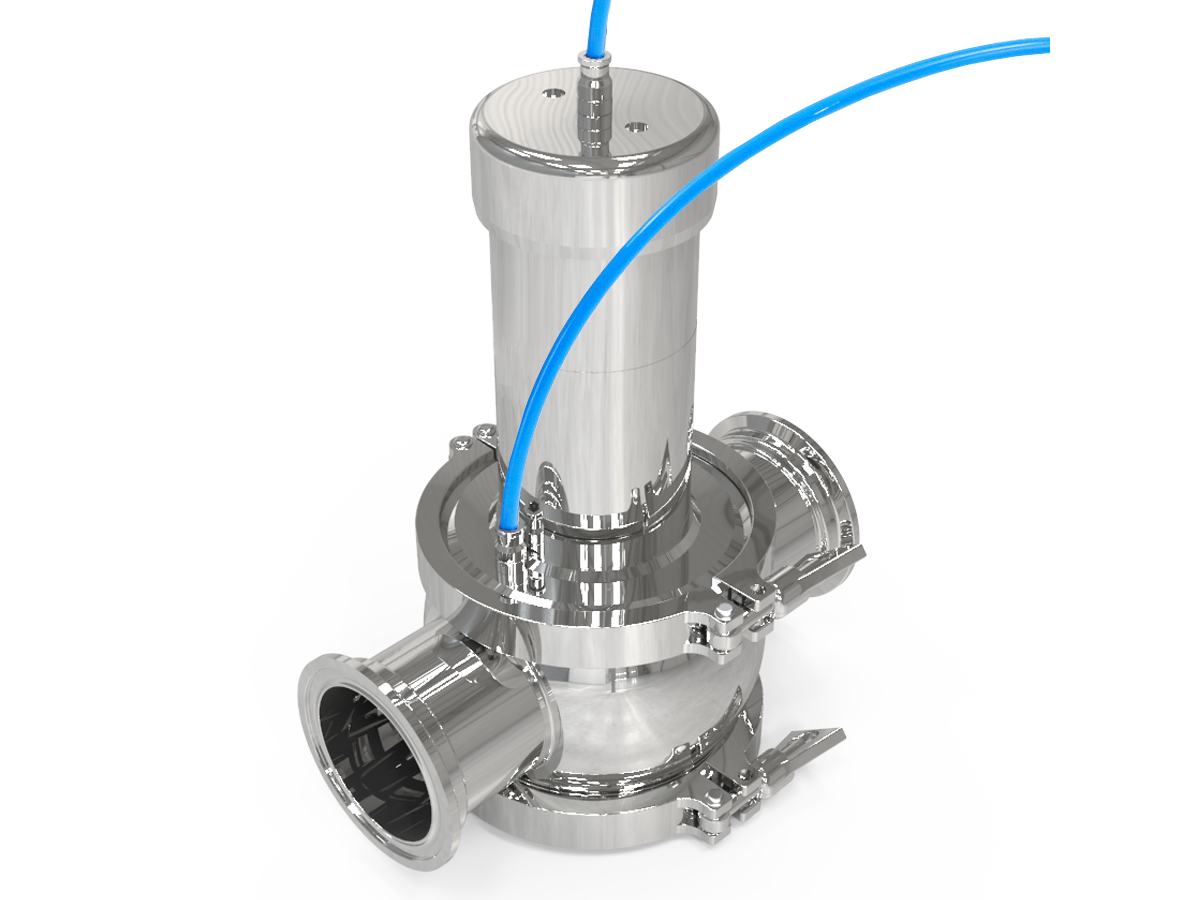

The spray drying of milk creates an additional risk of metal parts coming out of the spray towers. The specially developed EasyClean magnetic separators remove these metal particles, even from poorly flowing powders. With this new generation of magnets, the rod diameter, magnetic force and spacing have been optimised. Thus, even sticky products have a good flow.

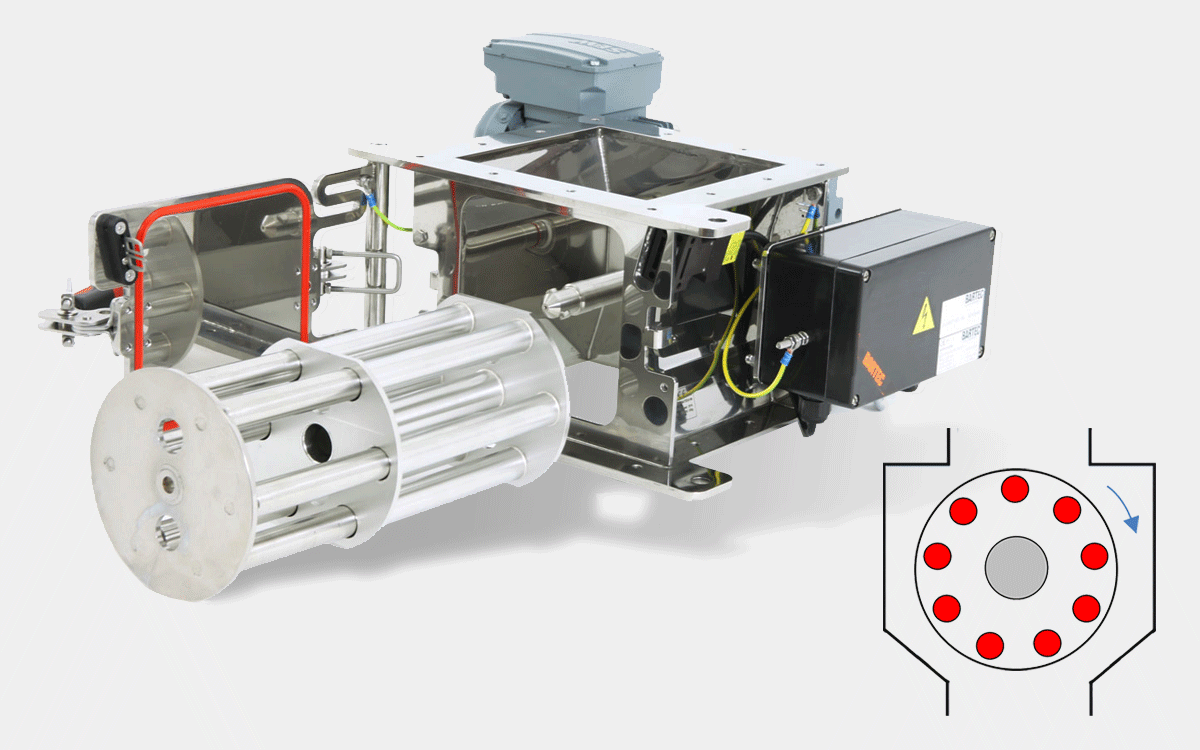

Rotating magnetic separators are suitable for really difficult-flowing, fatty powders. The turning of the rotor prevents bridging and blockages on the rods.

Rotating Cleanflow magnet filters metal particles from fatty powders

EHEDG magnets for High Care baby food

In the High Care departments in the production of milk powders for, among other things, baby food, the best separation and hygiene are a necessity. We have developed a special magnetic separator for this; the Hydrohansu Cleanflow magnet. This semi-automatic cleaning magnetic separator with rotating bars is EHEDG certified, has an extra high magnetic field strength and offers you the very best metal separation.

The EHEDG certified Hydrohansu Cleanflow magnet is specially made for milk powder

Custom advice: the right magnet in the right place

At Goudsmit, we always strive for the best separation result. By using different magnetic solutions in succession, or by filtering the metal particles at different stages of the process. If magnetic technology is not enough, we will also tell you.

Every product is different. We have an extensive testing centre available to determine the properties of your product. Practical tests give you and us quick insight to determine the right separator and location in the process. We will be happy to advise you after the analysis. This way, you are guaranteed the best metal separation and product quality.